Acoustic black hole sandwich flat plate vibration reduction structure

A vibration-reducing structure and black hole technology, which is applied in the direction of sound-generating devices and instruments, can solve the problems of high price and complex structure, and achieve the effects of low cost, satisfying sound insulation ability, and improving overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

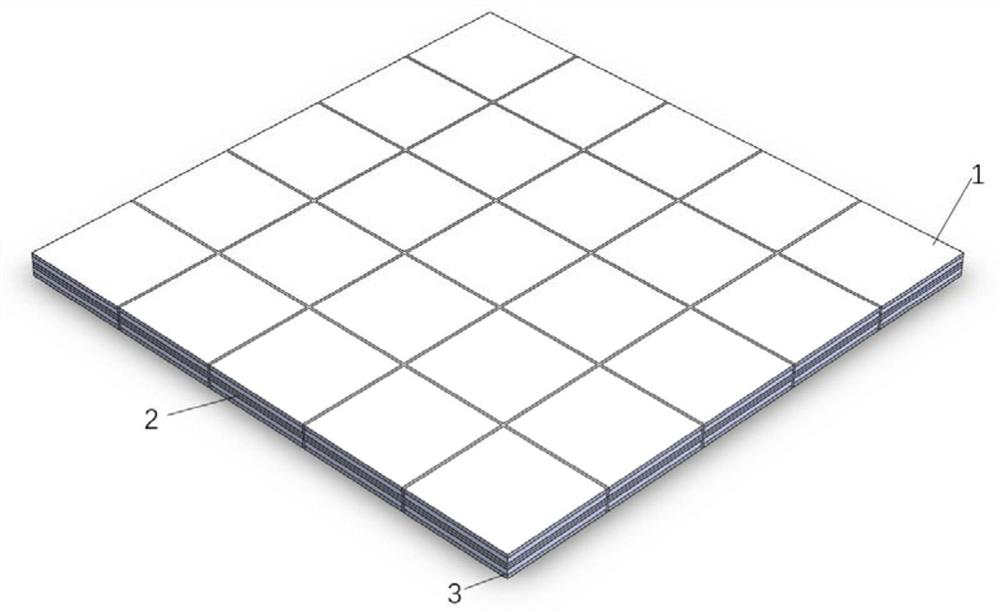

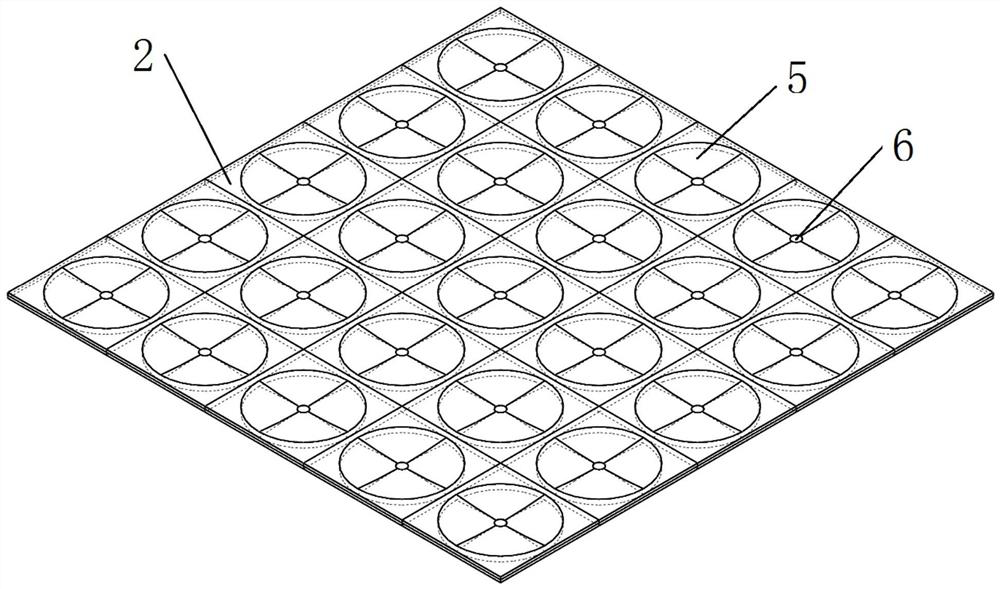

[0020] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, an acoustic black hole sandwich plate vibration damping structure of this embodiment, which includes a panel 1, a double-sided acoustic black hole embedded panel 2 and a back panel 3, the panel 1 and the back panel 3 are both square plates, and the panel 1 and one side plane of the back plate 3 are provided with an orthogonal stiffened plate 4, and there are multiple cavities 7 in the orthogonal stiffened plate 4, and multiple cavities 7 are embedded in the upper and lower sides of the double-sided acoustic black hole embedded plate 2. an acoustic black hole 5, and a truncated hole 6 is opened at the thinnest position of the thickness of the acoustic black hole 5, the panel 1, the double-sided acoustic black hole embedded board 2 and the back plate 3 are fixedly connected in order from top to bottom, and the double-sided acoustic black hole Each acoustic black hole 5 on the embedde...

specific Embodiment approach 2

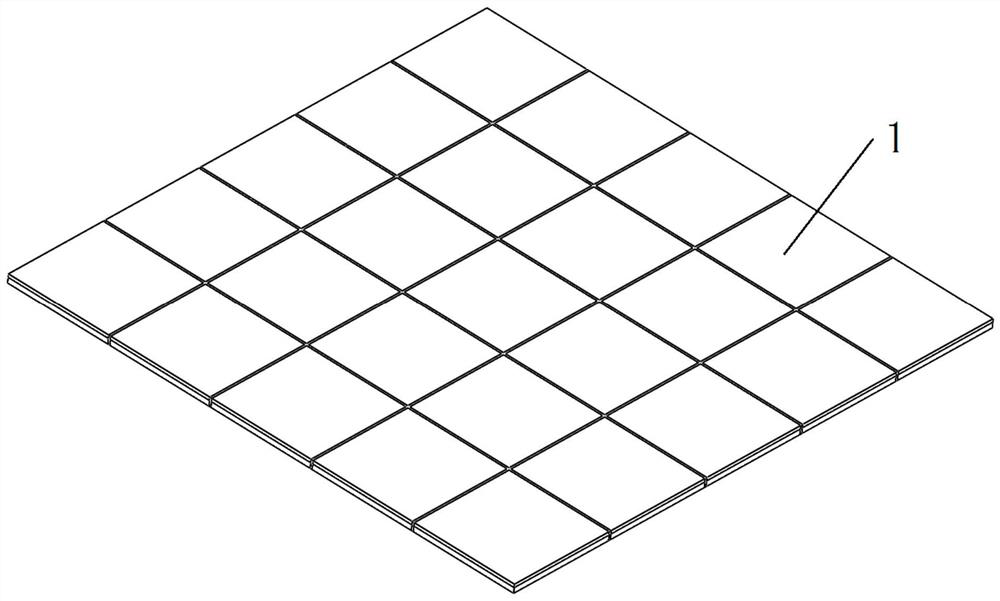

[0022] Specific implementation mode two: combination figure 2 with Figure 4 To describe this embodiment, both the panel 1 and the back plate 3 in this embodiment are square flat plates, and the cavity 7 is a square cavity. In such a setting, considering that a single acoustic black hole is formed by rotating a one-dimensional acoustic black hole, it has good symmetry, so the corresponding panels and cavities are designed to be square to ensure the excellent structural strength of the overall structure. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 Describe this embodiment, the panel 1, the double-sided acoustic black hole embedded panel 2 and the back panel 3 of this embodiment are fixedly connected by gluing or welding in order from top to bottom; or the panel 1, the double-sided acoustic black hole embedded panel 2 and the backplane 3 are integrally formed by 3D printing in order from top to bottom. Such setting can ensure the stability of the overall structure, and ensure that the experimental results can meet the actual needs when the frequency bandgap position is controlled by adjusting the size of the structure and material parameters. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com