An Acoustic Black Hole Sandwich Plate Vibration Damping Structure

A technology of vibration-damping structure and black hole, which is applied in the fields of acoustic black-hole sandwich plate vibration-damping structure, multi-layer composite sound insulation and vibration-damping structure, and sandwich plate. Sound insulation ability, environmental pollution-free effect

Active Publication Date: 2022-06-03

HARBIN ENG UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention solves the problem of complex structure and high price when the existing active control method is used to solve the vibration and noise reduction problem of the aircraft structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

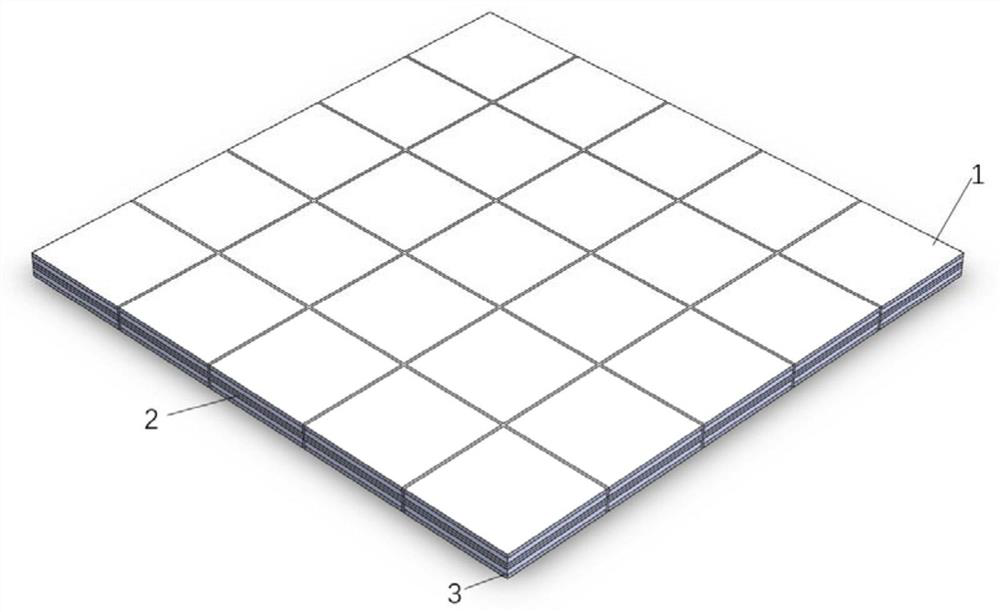

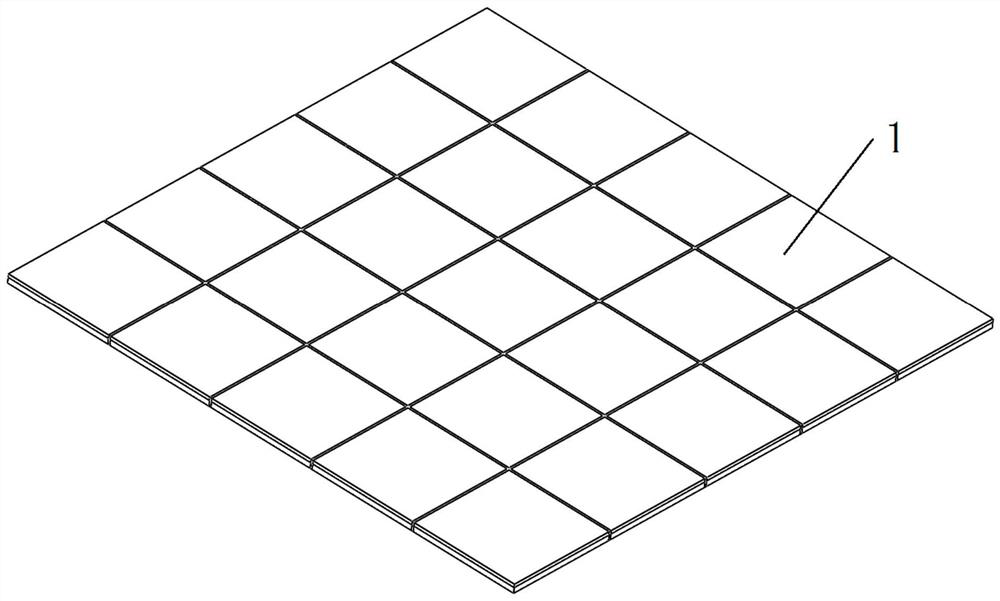

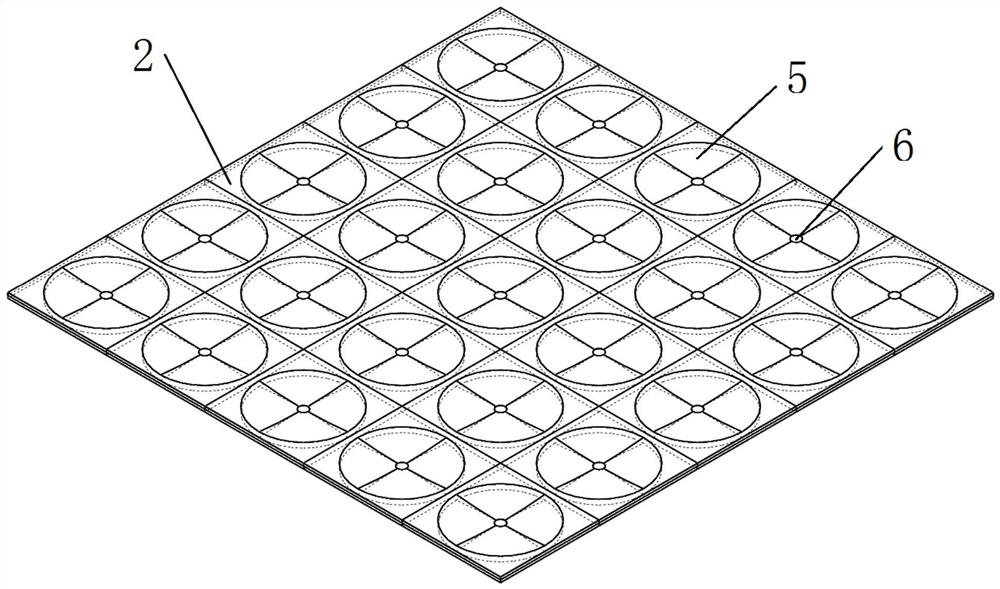

An acoustic black hole sandwich plate vibration damping structure relates to a sandwich plate. The invention solves the problem of complex structure and high price when the existing active control method is used to solve the vibration and noise reduction problem of the aircraft structure. One side plane of the panel (1) and the backboard (3) of the present invention is provided with an orthogonal stiffened plate (4), and there are multiple cavities (7) in the orthogonal stiffened plate (4). A plurality of acoustic black holes (5) are embedded on the upper and lower sides of the acoustic black hole embedding plate (2), and a truncated hole (6) is opened at the thinnest position of the acoustic black hole (5), and the panel (1), both sides The acoustic black hole embedding plate (2) and the back plate (3) are fixedly connected in order from top to bottom, and each acoustic black hole (5) on the bilateral acoustic black hole embedding plate (2) is embedded in a cavity (7) Inside, the acoustic black hole (5) embedded in the cavity (7) is a unit cell structure. The invention is used for vibration reduction and noise reduction of aircraft.

Description

An acoustic black hole sandwich plate vibration-damping structure technical field The present invention relates to a kind of sandwich plate, be specifically related to a kind of acoustic black hole sandwich plate vibration damping structure, is a kind of multi- A layered composite sound insulation and vibration reduction structure belongs to the field of vibration reduction and noise reduction of aerospace and ship structures. Background technique In the field of power machinery such as aerospace and ships, vibration and noise problems are more common. The existence of the aircraft will not only affect the normal operation of various equipment of the aircraft, but also greatly affect the life of the staff. Therefore, the problems of vibration and noise in the field of aircraft engineering have always been paid attention to. for sailing Generally speaking, the method of active control and passive control can be used to solve the problem of vibration reduction and noi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G10K11/162

CPCG10K11/162

Inventor 刘春川王朋王喆王阳绵傅康

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com