Feeder automation test system

A feeder automation and testing system technology, applied in the field of feeder testing, can solve problems such as system instability, test accuracy deviation, high defect rate of equipment, etc., and achieve accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

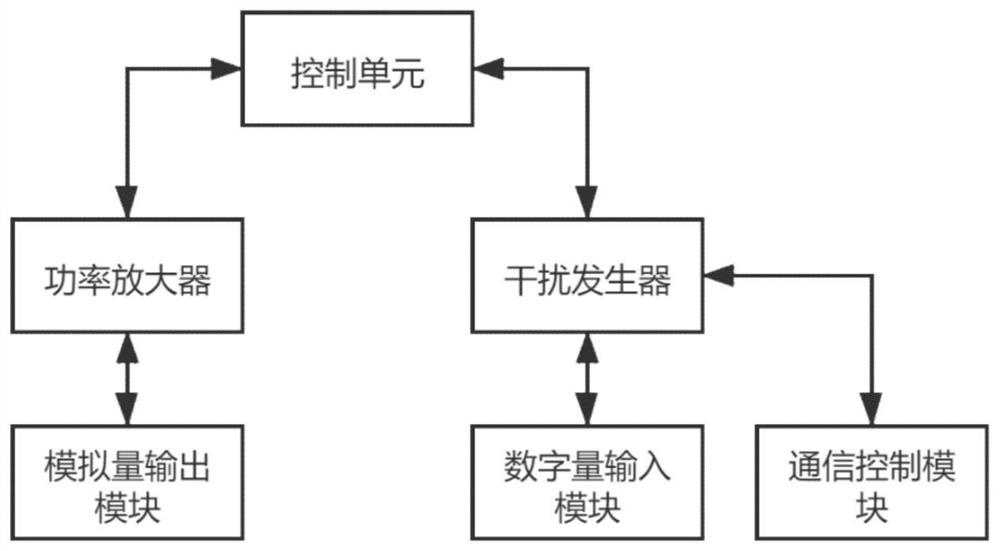

[0022] refer to figure 1 , as the first embodiment of the present invention, a feeder automatic test system is provided, and the feeder automatic test system includes a control unit, a power amplifier and a disturbance generator.

[0023] The control unit is used to complete analog output amplitude and angle control, analog output rectification and communication control, and conduct automatic test of feeder. The power amplifier is used to amplify weak voltage signals into AC current signals and AC voltage signals, and output them through the analog output module. Specifically, the power amplifier is connected to the control unit and the analog output module. The interference generator analyzes and interferes with the signal input to the control unit through the digital input module, and sends the control signal of the control unit through the communication control module. Specifically, the disturbance generator is connected to the control unit, the digital input module and t...

Embodiment 2

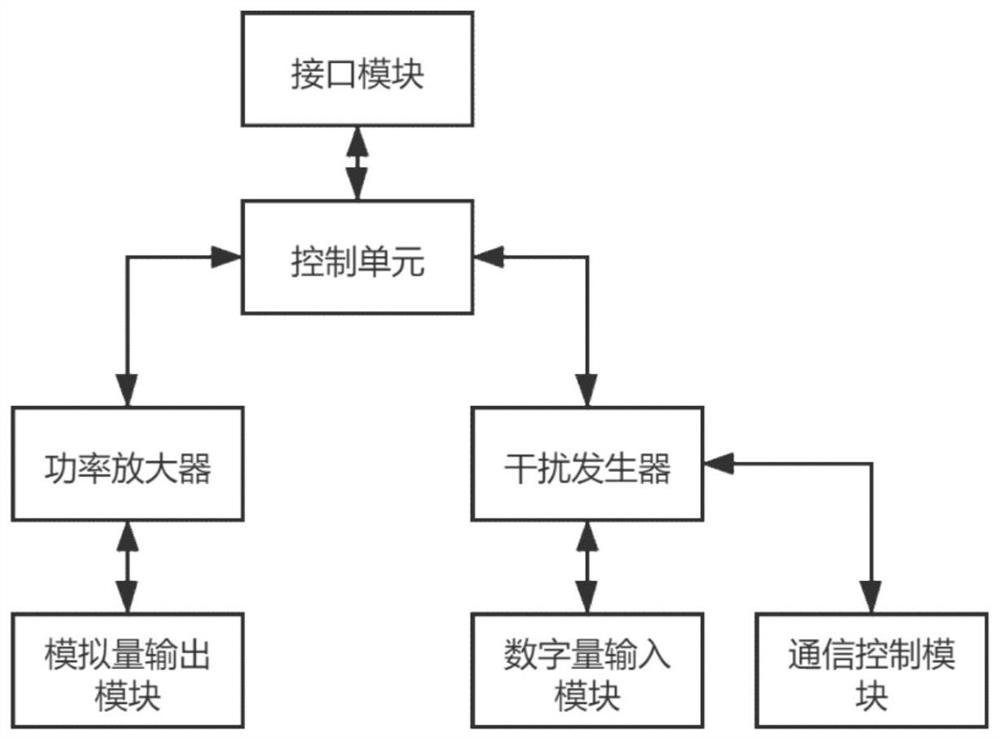

[0027] refer to figure 2 , is the second embodiment of the present invention, and this embodiment is different from the first embodiment in that: the control unit is also connected with an interface module, and the interface module includes a USB interface, a network port and a serial port.

[0028] Compared with Embodiment 1, further, this automatic feeder test system includes a control unit, a power amplifier and an interference generator.

[0029] The control unit is used to complete analog output amplitude and angle control, analog output rectification and communication control, and conduct automatic test of feeder. The power amplifier is used to amplify weak voltage signals into AC current signals and AC voltage signals, and output them through the analog output module. Specifically, the power amplifier is connected to the control unit and the analog output module. The interference generator analyzes and interferes with the signal input to the control unit through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com