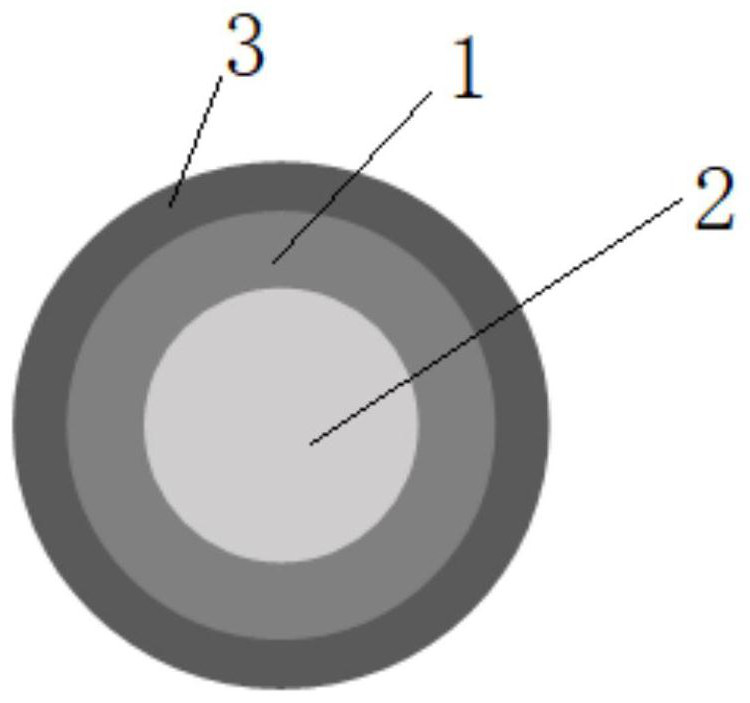

Cement paste temperature control self-repairing microcapsule and preparation method thereof

A microcapsule and self-healing technology, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of cementing quality decline, damaged layers, blowout accidents, etc., to improve mechanical strength, simple manufacturing process, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

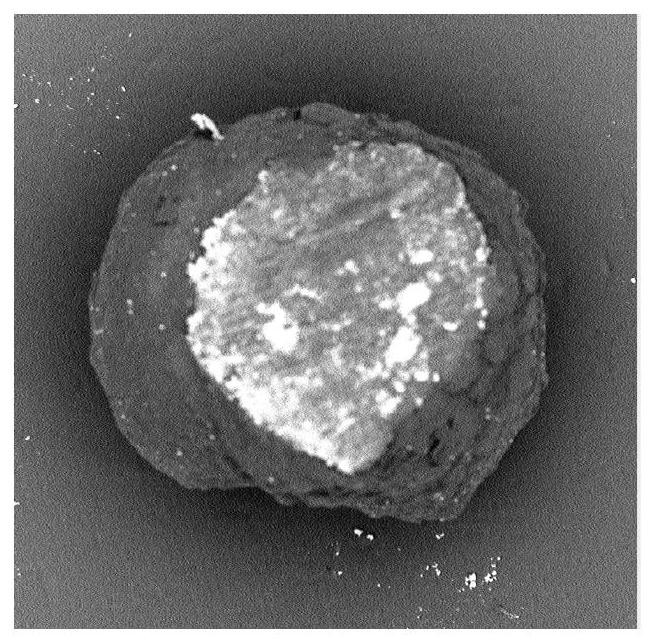

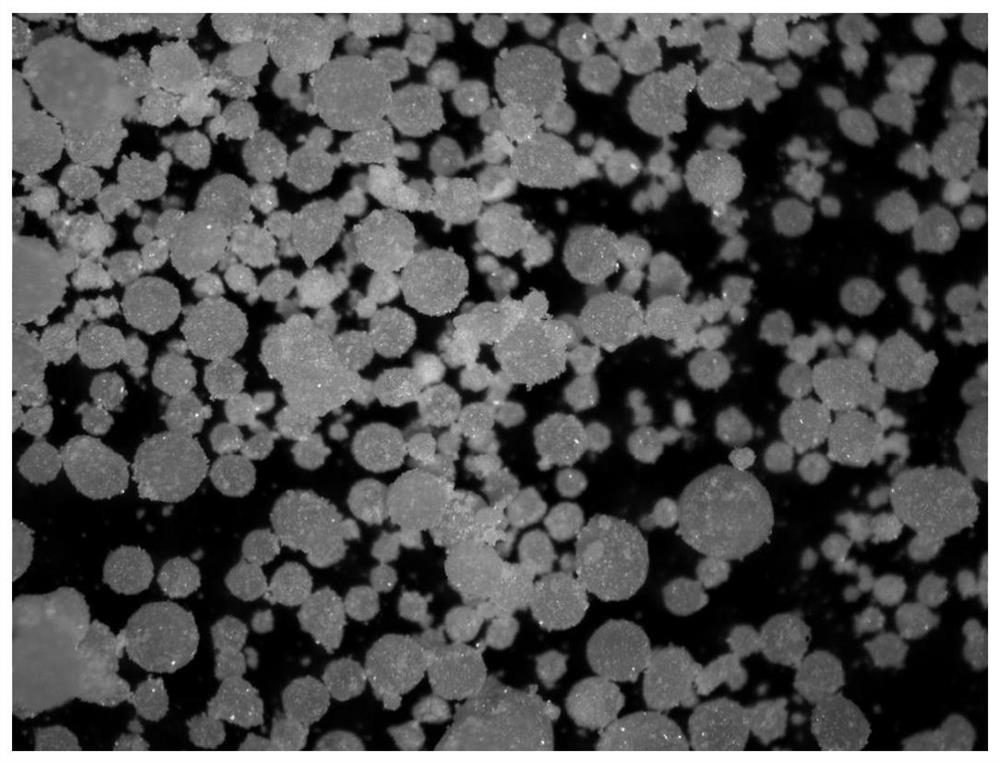

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the microcapsules for temperature-controlled self-repair of cement slurry, comprising the following steps:

[0044] Step S1, take the sliced paraffin and mix it with any proportion of low-carbon paraffin, heat it in a water bath to 55-65°C, and stir it with a magnetic stirrer until the paraffin-paraffin mixture dissolves into a transparent state; the proportion of low-carbon paraffin determines the control of the microcapsules. temperature range; among them, the carbon chain number of the main component of paraffin wax is between 18 and 30, and the carbon chain number of the main component of low-carbon paraffin is below 18, and its general formula is C n h 2n+2 , wherein, 5≤n<18; low-carbon paraffins can be any one or more of pentane, hexane...heptadecane;

[0045]Step S2, adding sodium dodecylbenzenesulfonate to the liquid in step S1, and fully stirring with a magnetic stirrer at a temperature of 55-65°C t...

Embodiment 1

[0053] Take 5g of sliced paraffin and 2.5g of low-carbon paraffins and mix them in a beaker, heat in a water bath to 60°C, stir with a magnetic stirrer at low speed until the paraffin paraffin mixture dissolves into a transparent state; add 0.15g of dodecane to the transparent liquid Sodium phenyl sulfonate, and fully stirred and emulsified with a magnetic stirrer at a speed of 400r / min at a temperature of 60°C to obtain a core material solution; weigh 3.75g of calcium chloride powder, stir and dissolve in deionized water, and prepare Calcium chloride solution with a solute mass fraction of 20%; slowly add the calcium chloride solution dropwise to the core material solution, and stir at a speed of 350r / min with a magnetic stirrer while heating in a water bath at a temperature of 60°C 1h, obtain the first mixed solution; Take 2.25g sodium carbonate powder and dissolve in deionized water, prepare sodium carbonate solution, add 0.75gE-51 epoxy resin and ethanol to the sodium car...

Embodiment 2

[0058] Take 5g of sliced paraffin and 5g of low-carbon paraffin and mix them in a beaker, heat in a water bath to 58°C, and stir at a low speed with a magnetic stirrer until the paraffin and paraffin mixture dissolves into a transparent state; add 0.15g of dodecyl to the transparent liquid Sodium benzenesulfonate, and fully stirred and emulsified with a magnetic stirrer at a speed of 500r / min for 30min at a temperature of 58°C to obtain a core material solution; weigh 4.5g of calcium chloride powder, stir and dissolve in deionized water, and prepare Calcium chloride solution with a solute mass fraction of 20%; slowly add the calcium chloride solution dropwise to the core material solution, and stir at a speed of 350r / min with a magnetic stirrer while heating in a water bath at a temperature of 58°C 1h, obtain the first mixed solution; Take by weighing 3.5g sodium carbonate powder and dissolve in deionized water, prepare sodium carbonate solution, add 0.8gE-51 epoxy resin and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com