Plastic bottle filling machine

A filling machine, plastic bottle technology, applied in packaging, packaging protection, packaging sterilization and other directions, can solve the problems of microbial death, bacterial residues, contamination of filling products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

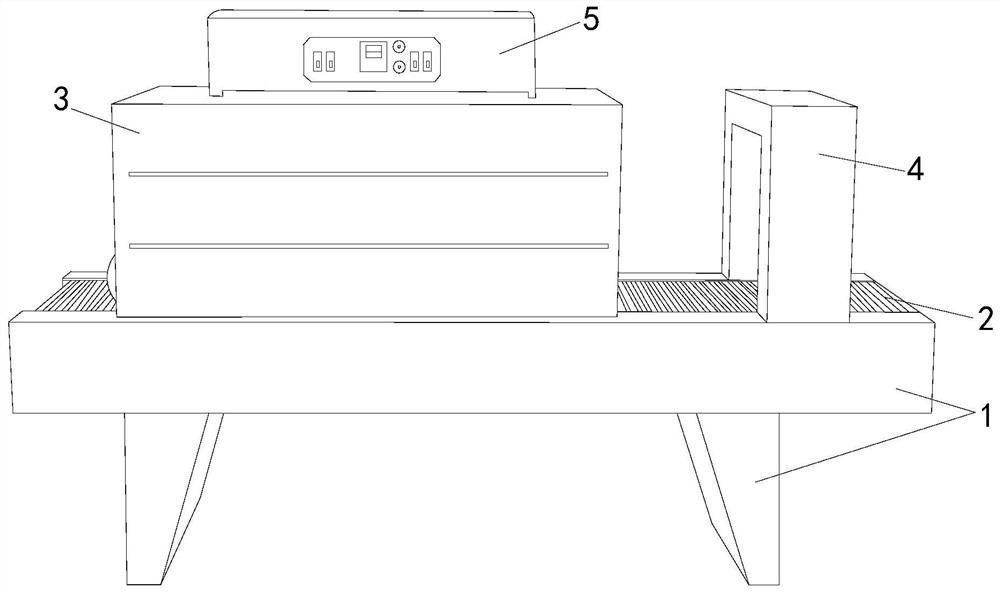

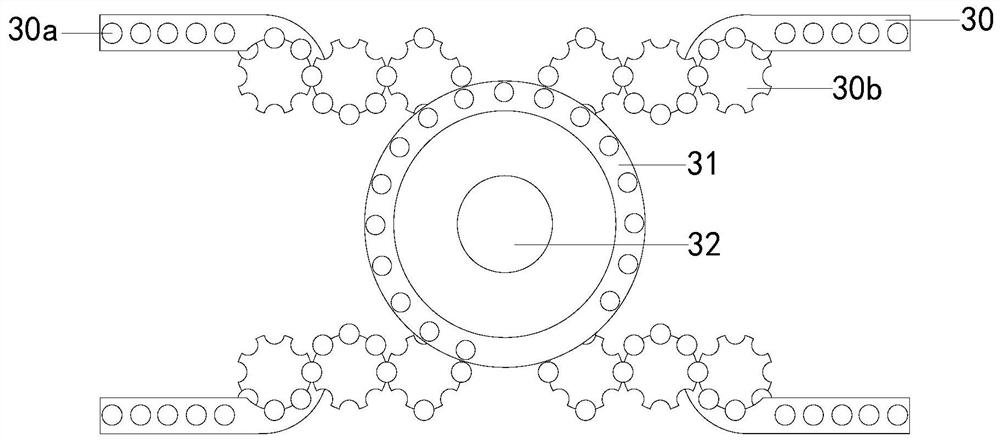

[0024] see figure 1 , the present invention provides a plastic bottle filling machine, the structure of which includes: a conveyor frame 1, a conveyor track 2, a filling mechanism 3, a light sterilizer 4, and a control box 5. The top surface of the conveyor frame 1 is connected to the conveyor Track 2, a filling mechanism 3 and a light sterilizer 4 are arranged on the transmission track 2, and the two are spaced apart from each other. The carrier of the conveying structure used to transport empty plastic bottles to be processed by the filling mechanism 3 and sterilized by the light sterilizer 4. The conveying track 2 connected by the top surface keeps the structural position of the filling mechanism 3 and the light sterilizer 4 unchanged Under the circumstances, it can maintain a fixed frequency of irradiation and filling with each plastic empty bottle to ensure the high-speed filling and sterilization efficiency. The filling mechanism 3 processes the filling and transports i...

Embodiment 2

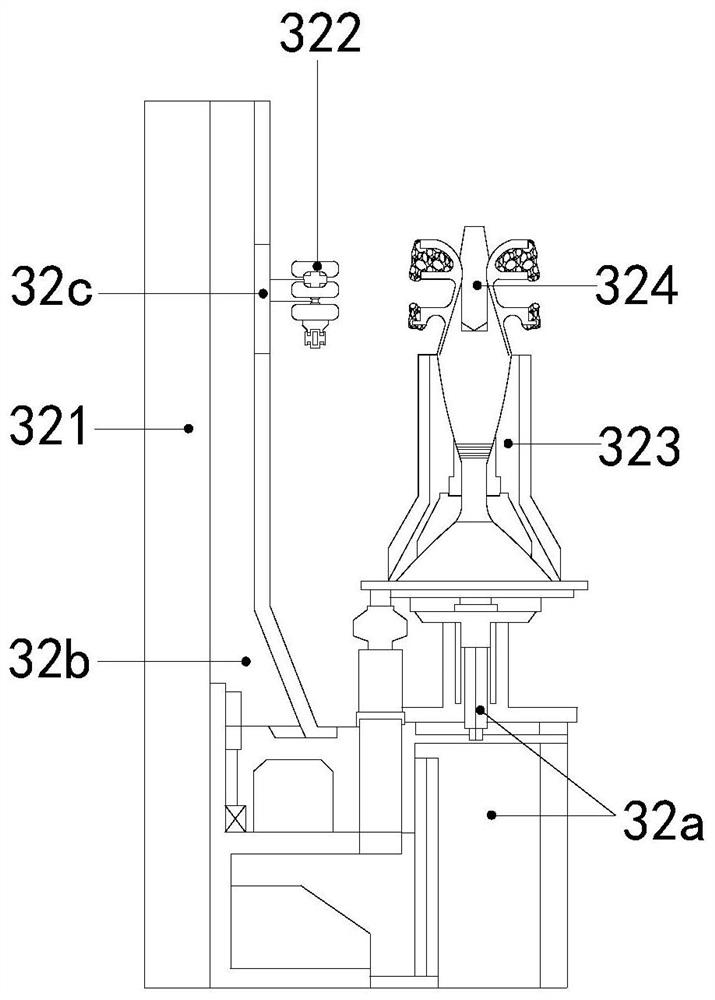

[0031] The description of the second embodiment drawn in conjunction with the first embodiment, combined with image 3 , Figure 4 , Figure 5 and Image 6 , the inner side of the bottle stand 321 is provided with a bottle mouth brush roller 322, the bottle body sticking column 323 is located on the surface of the bottle stand 321 and one end thereof is connected to the inner light pipe 324 of the bottle, the roller shaft 3220 is connected to the adsorption bag wheel 3221, The bottom of the adsorption capsule wheel 3221 is provided with honeycomb brush wheels 3222 at intervals, and the adjacent positions below the honeycomb brush wheels 3222 are connected with threaded brush wheels 3223 at intervals, and the two sides of the trapezoidal column 3230 are provided with convection grids 3231 and connected with expansion glue layers 3232 , the outer layer of the expansion rubber layer 3232 is connected to the water-absorbing column sleeve 3233, and the sides of the astigmatism tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com