Water cutting knife nozzle and driving device for driving water cutting knife nozzle

A driving device, a technology of water jet cutter, applied in the direction of metal processing, etc., can solve the problems of difficult to adjust accurately, high labor intensity, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

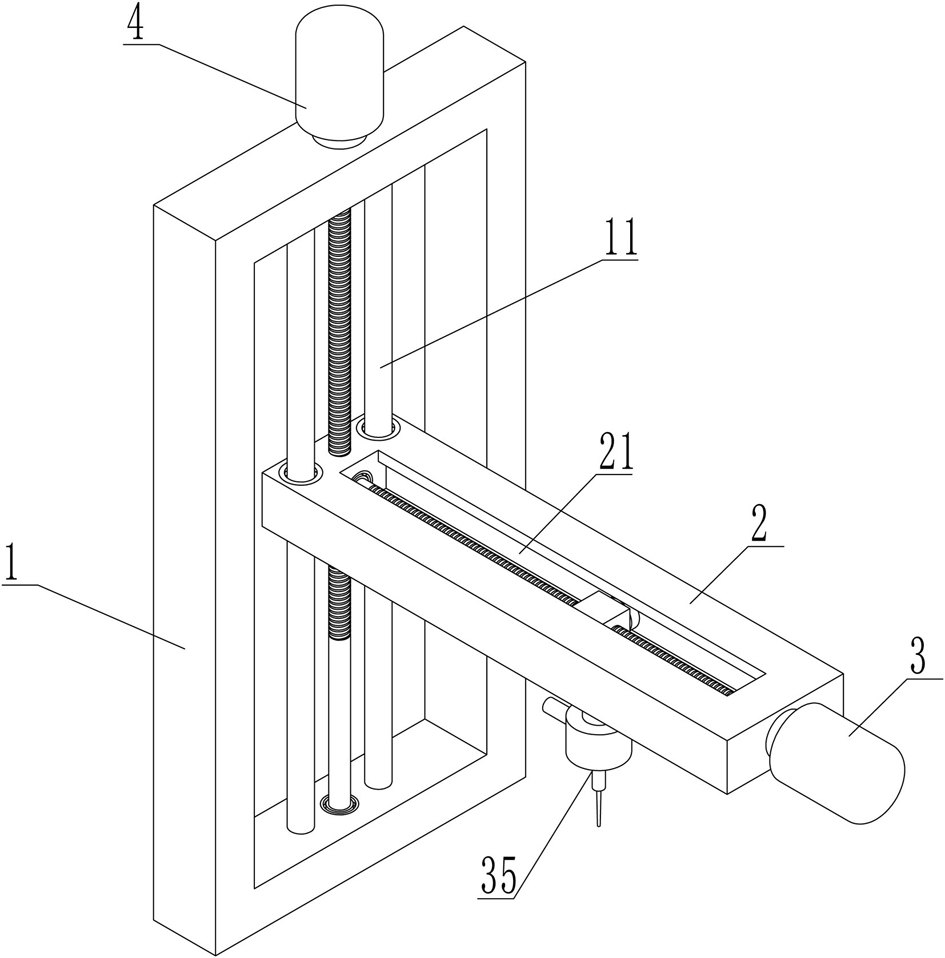

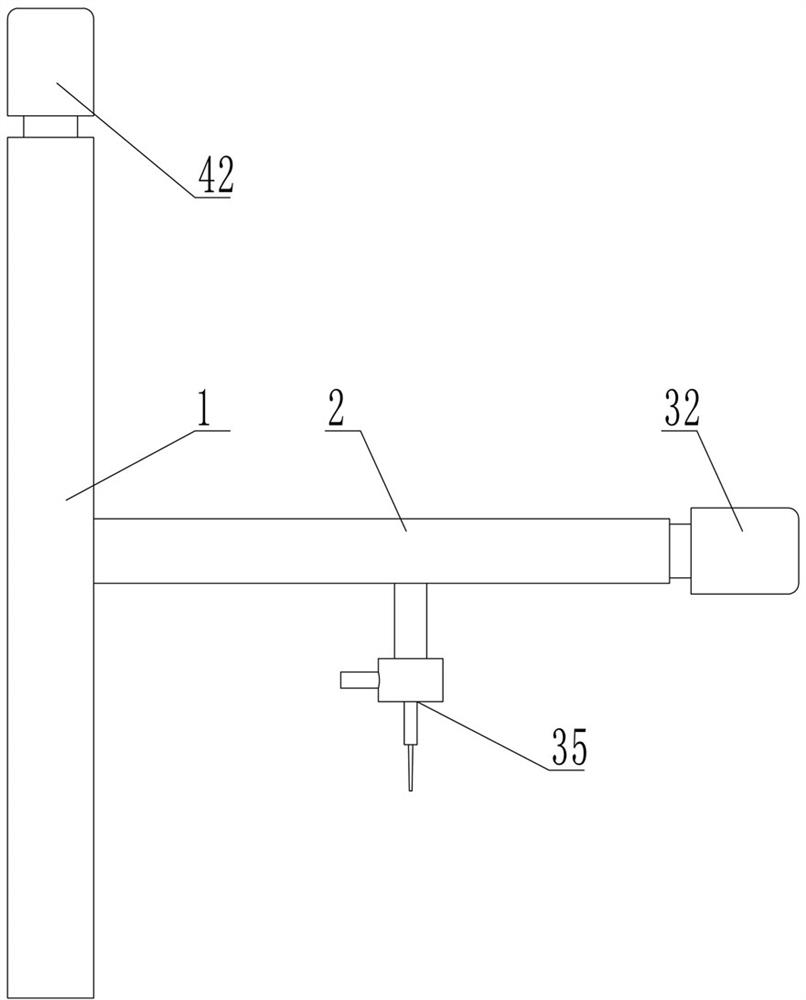

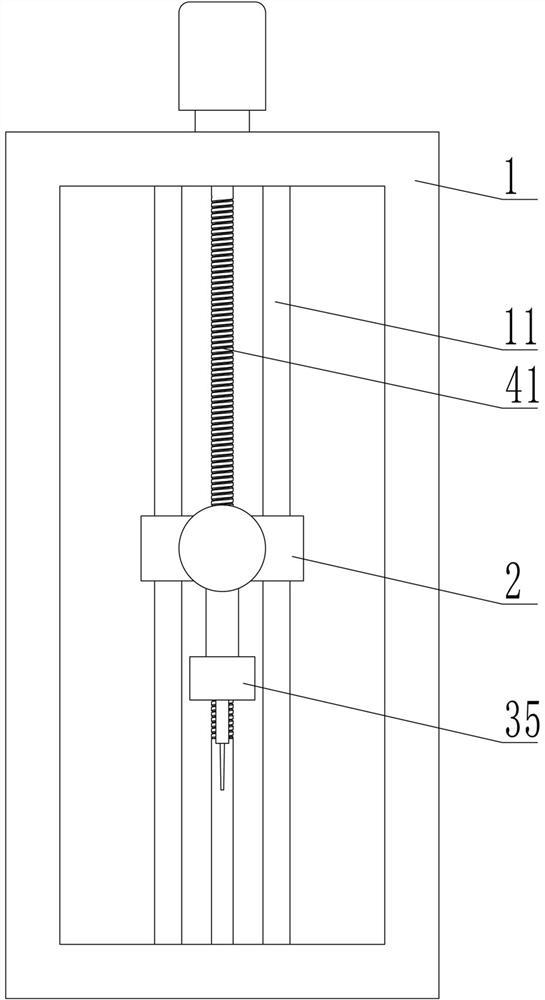

[0033] Such as Figure 1~Figure 6 Among them, a water cutting knife nozzle and driving device for driving the water cutting knife nozzle, it includes a support frame 1, a knife rest 2, a knife adjustment mechanism 3 and a knife rest adjustment mechanism 4; the horizontal screw rod 31 of the knife adjustment mechanism 3 wears The knife rest 2 cooperates with the knife seat 33, and the water cutting knife 35 connected with the knife seat 33 hangs from the lower part of the knife rest 2. The vertical screw rod 41 passes through the support frame 1 and cooperates with the tool holder 2; the horizontal screw rod 31 rotates to drive the knife seat 33 to drive the water cutter 35 to move horizontally, and the vertical screw rod 41 rotates to drive the tool holder 2 to vertically lift. The structure is simple, and one end of the tool holder 2 is slidably matched with the positioning rod 11 of the support frame 1, the side of the tool holder 2 is perpendicular to the support frame 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com