Multifunctional impurity removal device for recovering methylbenzene in production of sym-triazobenzene herbicides

A technology of s-triazines and herbicides, which is applied in the field of impurity removal devices for recovering toluene in the production of multi-functional s-triazines herbicides, and can solve the problems of inconvenient slag discharge, inconvenient cleaning of stills, and lack of Problems such as storage and collection of filtered slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

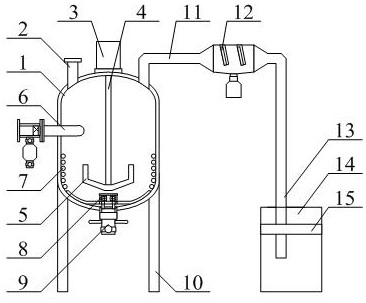

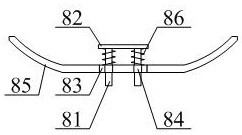

[0040] as attached figure 1 And attached image 3 shown

[0041]The invention provides a kind of impurity removal device for recovering toluene in the production of multifunctional s-triazine herbicides, which comprises a reaction kettle 1, an upper side feeding pipe 2, a stirring motor 3, a transmission rod 4, a U-shaped stirring frame 5, a material Slag filter collection frame structure 6, heating pipe 7, dust-proof pad slag hanger structure 8, rotating drive frame structure 9, longitudinal support 10, air outlet pipe 11, water-liquid separation frame structure 12, L-shaped conduit 13, collection box 14 and the adsorption layer 15, the upper feed pipe 2 is plugged on the left side of the upper part of the reactor 1; the stirring motor 3 bolts are installed on the middle and upper part of the reactor 1; the transmission rod 4 is arranged on the reactor The inner side of the kettle 1, while the bolts are installed on the lower output shaft of the stirring motor 3; the bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com