Automobile high-voltage wiring harness wire-passing protection structure

A high-voltage wiring harness and protection structure technology, which is applied to vehicle components, electrical components, circuits or fluid pipelines, etc., can solve the problems of the rubber components of the wiring harness sleeves coming out, the increase of reliability risk points, and water leakage, so as to improve the installation reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

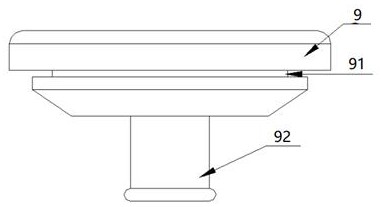

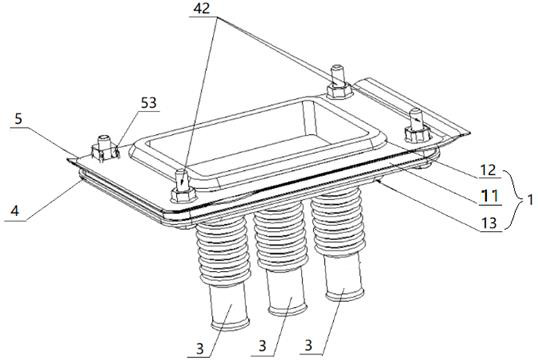

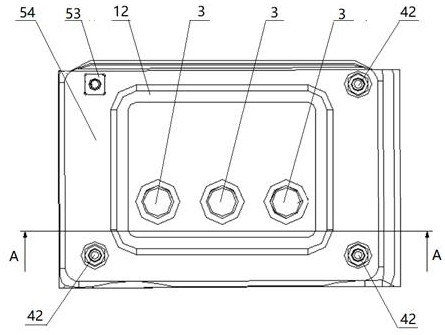

[0036] see Figure 2 to Figure 10 The shown a kind of protective structure of automobile high-voltage wire harness, comprises rubber member 1, waterproof sealing ring 2, wire harness casing 3, body member 5, and the mounting part 11 of described rubber member 1 cooperates with body member 5 above, and described The waterproof sealing ring 2 is arranged at the matching part of the rubber member 1 and the body member 5, which effectively solves the problem of airtightness and waterproofness of the whole vehicle affected by the rubber member due to long-term tension; multiple wire harness sleeves 3 are fixedly connected to the The middle part of the rubber member 1 is characterized in that: a sheet metal member 4 is in close contact with the mounting part 11 of the rubber member 1, and is connected to the body member 5 by a threaded fastener; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com