Connector

A technology of connectors and grounding terminals, which is applied in the field of signal transmission, can solve problems such as unreliable assembly of wafers and shells, and achieve the effects of low overall shape requirements, improved assembly reliability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

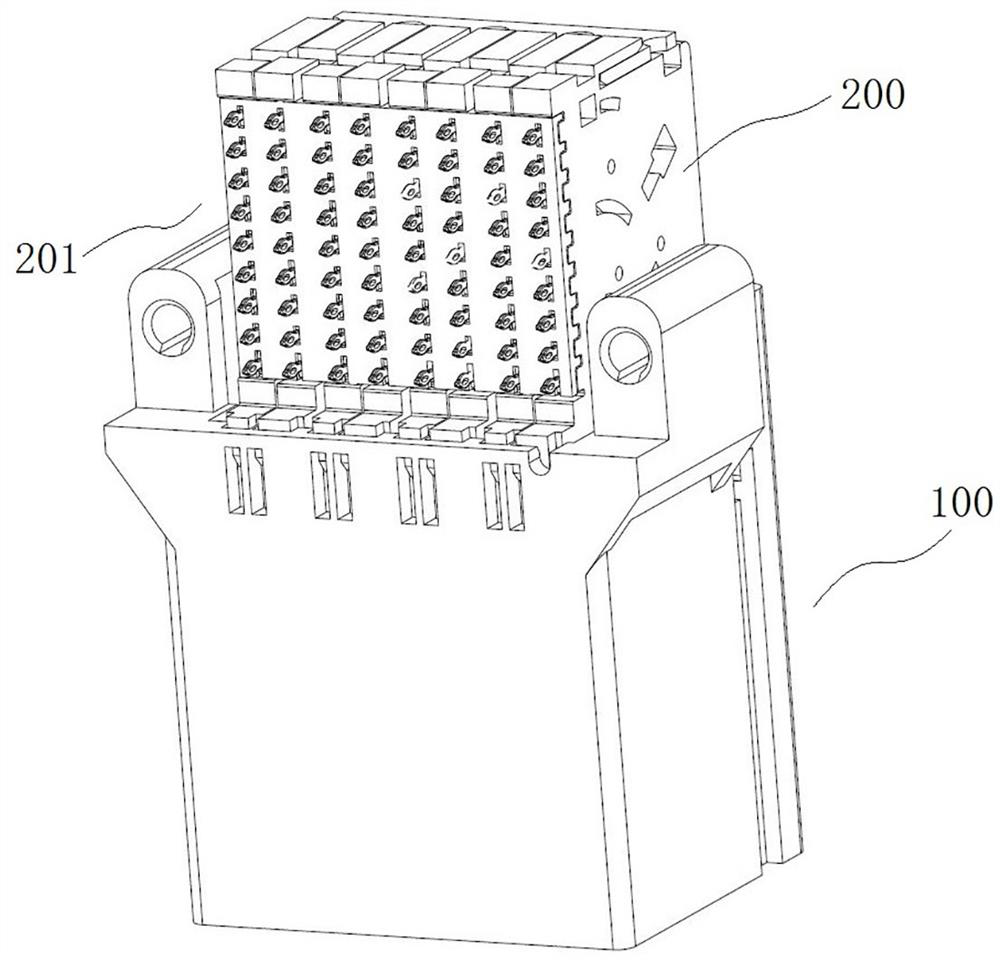

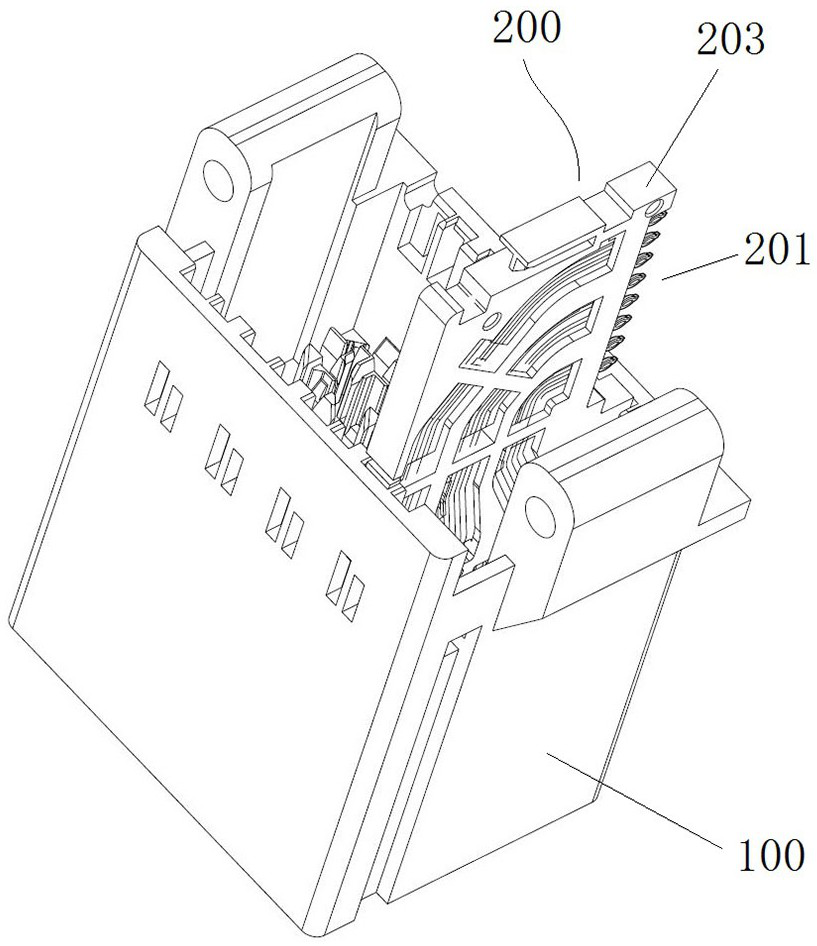

[0085] Such as Figure 1 to Figure 14 As shown, in this embodiment, the orthogonal connector is taken as an example to illustrate the related structure of the connector. The mating connector is mounted on the second circuit board when in use, and the first circuit board and the second circuit board are arranged orthogonally. The orthogonal connector includes a housing 100 in which multiple (at least two) wafers 200 are arranged. There are signal terminals 204 and grounding terminals 205 in the housing 100. The signal terminals 204 and grounding terminals 205 are installed at one end when in use. On the first circuit board, the other end is used to insert the signal terminal and the ground terminal in the matching connector.

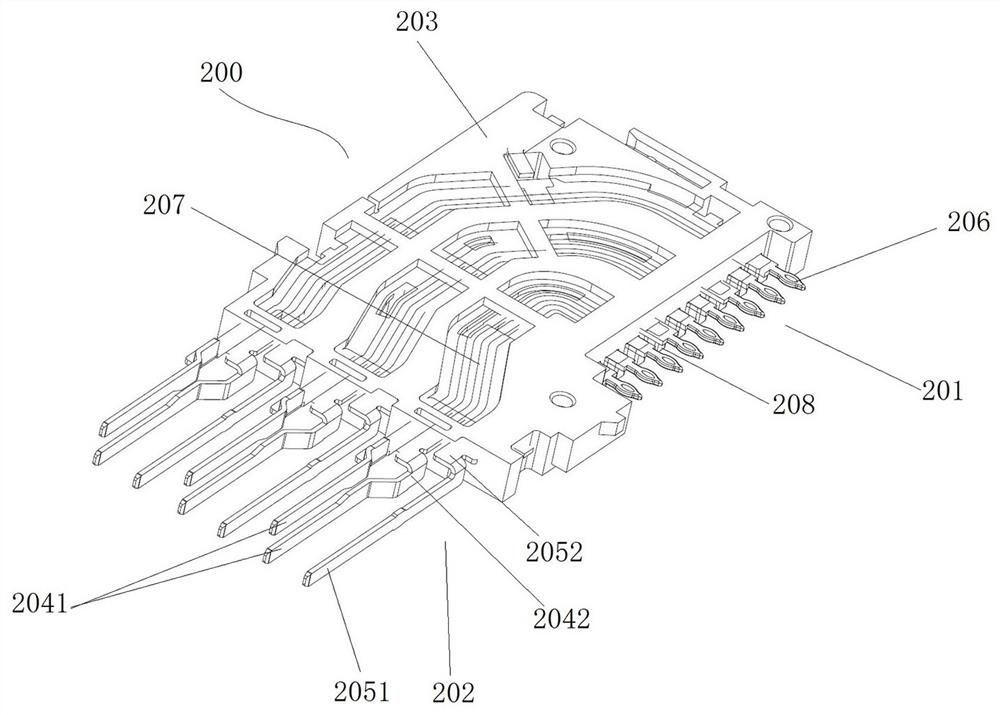

[0086] The structure of wafer 200 is as image 3 and Figure 4 As shown, the chip 200 includes an insulating frame 203 on which three signal differential pairs and three ground terminals 205 are fixed. The signal differential pairs and the ground termi...

Embodiment 1

[0108] In Embodiment 1, the grounding column is a rectangular column. In this embodiment, the shape of the grounding post may be cylindrical or other shapes.

specific Embodiment 3

[0110] In Embodiment 1, the grounding post is inserted into the grounding contact socket, and the end surface of the grounding post is flush with the surface of the separator. In this embodiment, the end surface of the grounding post may be located inside the grounding contact socket in the partition. Alternatively, in other embodiments, the grounding post may not be inserted into the grounding contact socket, that is, the grounding contact socket is small, and the grounding post is located at one side of the grounding contact socket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com