PEMFC electric pile temperature control method and system

A temperature control method and stack technology, applied in fuel cell control, circuits, fuel cells, etc., can solve problems such as affecting service life, temperature rise, and excessive temperature difference between inlets and outlets, to ensure reliable operation, prolong service life, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

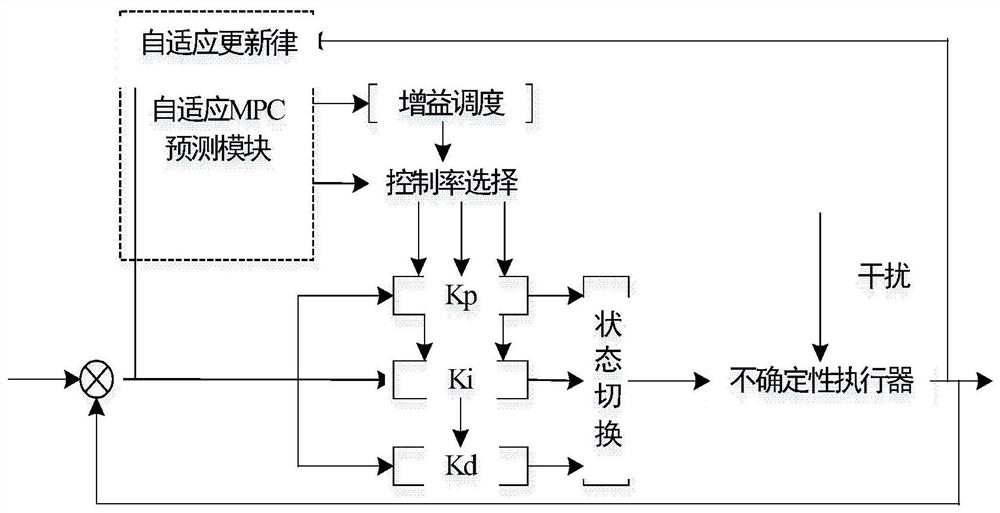

[0029] Such as figure 1 As shown, the present embodiment provides a method for controlling the temperature of a PEMFC stack. Taking the specific application to a water-cooled PEMFC stack as an example, the precise temperature control of the water-cooled PEMFC stack under different operating conditions, the water-cooled PEMFC stack The stack model includes cooling water circuit, radiator, cooling water pump and temperature sensor; the controlled objects of the water-cooled PEMFC stack model are cooling water pump and radiator, the manipulated variable is the inlet and outlet temperature of the PEMFC stack, and the target output current value of the PEMFC stack is taken as Amount of mutation perturbation. Its specific steps include:

[0030] Step 1: Obtain the volt-ampere characteristic curve of the PEMFC stack model, and use the target optimal temperature under different current values as the initial temperature value;

[0031] Step 2: Adjust the PID control parameters of t...

Embodiment 2

[0044] The present embodiment provides a PEMFC stack temperature control system, including:

[0045] The initial module is used to obtain the volt-ampere characteristic curve of the PEMFC stack model, and the target optimal temperature under different current values is used as the initial temperature value;

[0046] The optimization module is used to regulate the PID control parameters of the PEMFC stack model according to the gain change rate of the PEMFC stack inlet and outlet temperature relative to the PEMFC stack state change and the target current value at adjacent moments;

[0047] The control module is used for controlling the temperature at the inlet and outlet of the PEMFC electric stack according to the PID control parameter and the initial temperature value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com