Magnetic field orientation method and device for tape casting of magnetic materials and product

A tape-casting, magnetic material technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low efficiency, weak orientation ability, cumbersome installation, etc., to achieve flexible and convenient operation, high orientation efficiency , the effect of uniform intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The magnetic field orientation device and method for tape casting of magnetic materials provided by the embodiments of the present invention are used to prepare a magnetic thin film in which magnetic fillers are oriented vertically or along the length direction of the film.

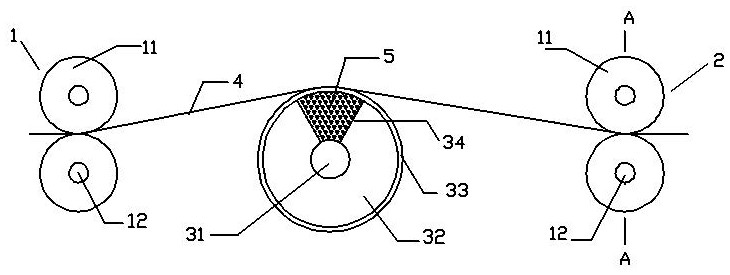

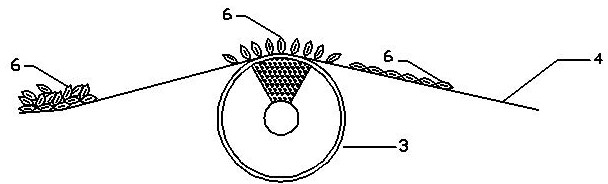

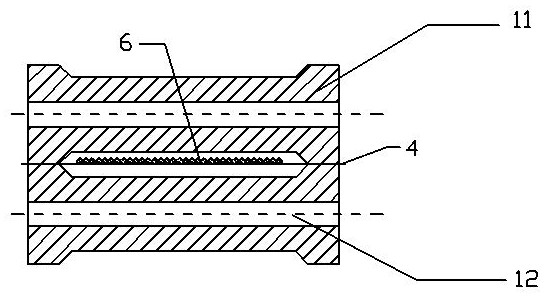

[0055] The magnetic field orientation device for tape casting of magnetic materials provided in this embodiment includes a tape casting machine and its support (not shown in the drawings), and also includes the first limiting pair of rollers 1 and the magnetic field orientation roller sequentially arranged on the support. 3, the second position-limiting pair of rolls 2, and the cast base tape 4 passing through the first position-limiting pair of rolls 1, the magnetic field orientation roll 3, and the second position-limiting pair of rolls 2 in sequence; The slurry is scraped and coated by a scraper, etc.) The cast slurry to be tape-casted, the slurry includes magnetic fillers to be oriented; in this...

Embodiment 2

[0072] The magnetic field orientation device, method and product provided by the embodiment of the present invention are basically the same as the embodiment 1, and it is used to prepare a magnetic thin film in which the orientation of the magnetic filler is perpendicular to the length direction of the film. The difference is that:

[0073] In the magnetic field orientation device for tape casting of magnetic materials provided in this embodiment, the horizontal height of the top arc section where the magnetic field orientation roller 3 is in contact with the casting base tape 4 is higher than the position where the first limiting pair of rollers 1 contacts the casting base tape 4 Horizontal height, at the arc-shaped top position of this section, the casting base belt 4 is lifted upwards, so that the casting base belt 4 forms a slope of 2 to 8° between the first limiting pair of rollers 1 and the top of the magnetic field orientation roller 3 , that is to form an uphill sectio...

Embodiment 3

[0085] The magnetic field orientation device, method and product provided by the embodiments of the present invention are basically the same as those in Embodiments 1 and 2, and are used to obtain a magnetic field in which the orientation of the magnetic filler is aligned along the length direction of the film. film. The difference is that:

[0086] In the magnetic field orientation device tape-casting of the magnetic material, the horizontal height of the top arc section of the magnetic field orientation roller 3 contacting the casting base tape 4 is higher than the horizontal height of the position where the second limiting pair of rollers 2 contacts the casting base tape 4, The casting base tape 4 is lifted up at the position of the top arc section, so that the casting base tape 4 forms a slope of 2 to 8° between the second position-limiting pair of rollers 2 and the top of the magnetic field orientation roller 3, that is, a gradient from the magnetic field is formed. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com