A high-speed large-scale paper output device

A large-scale paper, high-speed technology, applied in the field of conveying and outputting devices, can solve the problems of time consumption, low production efficiency, increased lamination time, etc., to achieve the effect of ensuring the transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

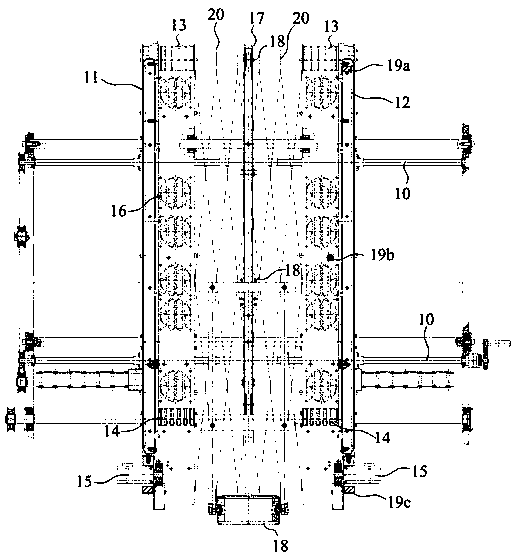

[0016] A high-speed large-scale paper output device of the present invention includes a two-way screw 10, a pair of paper feeding groove sides 11, 12 arranged on the two-way screw, and several reeds 20 pass between the paper feeding groove sides 11, 12 Connected, the two-way screw rod 10 is driven to rotate by a servo motor or a stepping motor, so that the sides 11 and 12 of the paper feeding groove are expanded along the slide bar to both sides or contracted toward the middle, so that the reed 20 is deformed and the paper feeding width is changed.

[0017] The reeds 20 are flush with the surfaces of the sides 11, 12 of the paper feeding trough, and play the effect of supporting the middle part of the facial paper, while the reeds are arranged in a longitudinal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com