Double-wall high-performance refueling limiting valve and working method thereof

A working method, high-performance technology, applied in the direction of functional valve type, valve operation/release device, lift valve, etc., can solve the problems of opening the fuel limit valve and high pressure of the fuel tank system, to eliminate pressure, improve safety, reduce hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

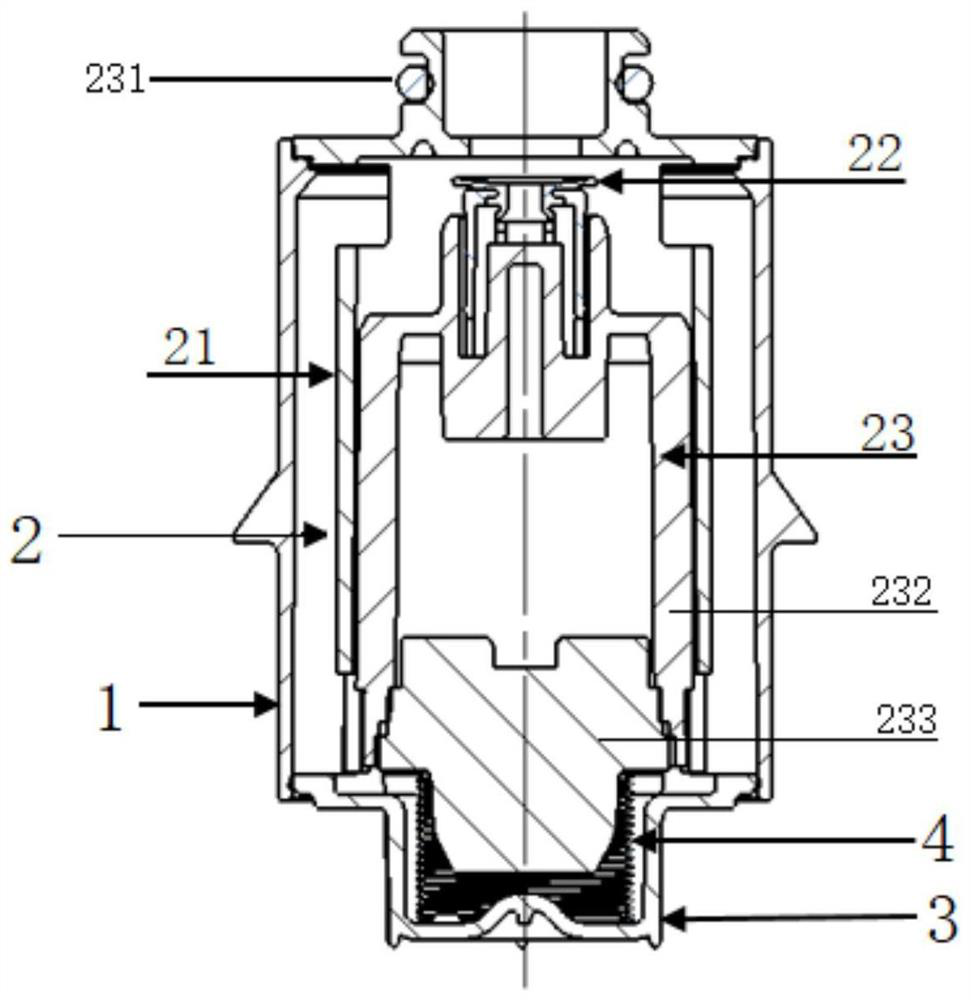

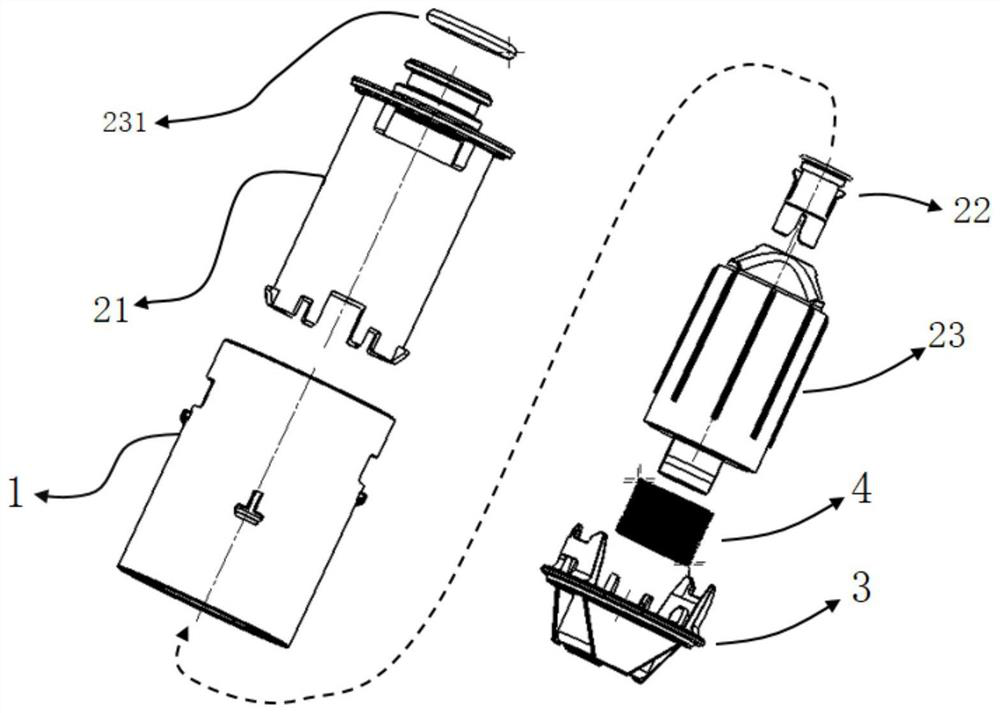

[0055] Based on the above structural basis, such as Figure 1~15 As shown, the working method of the double-wall high-performance refueling limit valve of the present invention, the working method includes the following steps:

[0056] (1) Refueling: During the refueling process, as the oil in the tank rises, when the oil reaches the oil hole 11, the oil flows into the casing 1 through the oil hole 11 of the casing 1, and the float 33 is in the oil After entering, under the effect of buoyancy, it rises rapidly, and drives the airtight door 32 to rise together until the first-level opening vent hole 221 and the second-stage opening vent hole 212 are in a closed state. At this time, the refueling is completed;

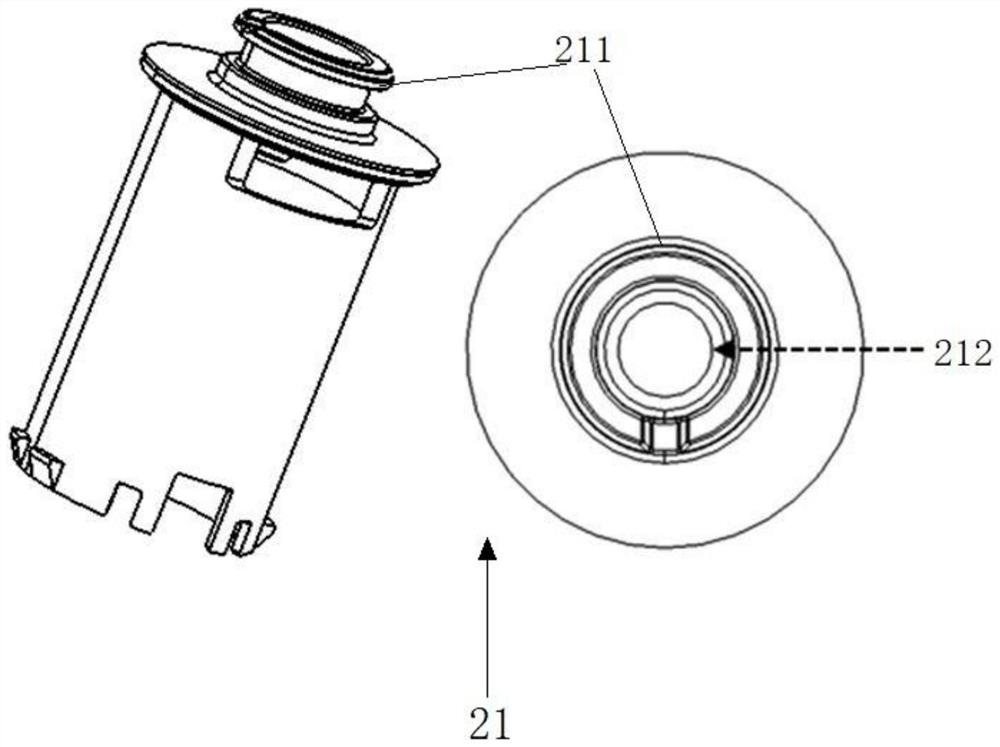

[0057] (2) Exhaust: The oil in the fuel tank gradually decreases with use. The more oil vapor is generated in the fuel tank, the greater the pressure in the fuel tank. The area is small, the area corresponding to the second-stage opening vent hole 212 is large, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com