Acidification outburst elimination effect evaluation method

A coal seam and dissolution technology, applied in the direction of earthwork drilling, wellbore/well components, instruments, etc., can solve problems such as coal material degradation, coal and gas outburst, and achieve the effect of ensuring authenticity and objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

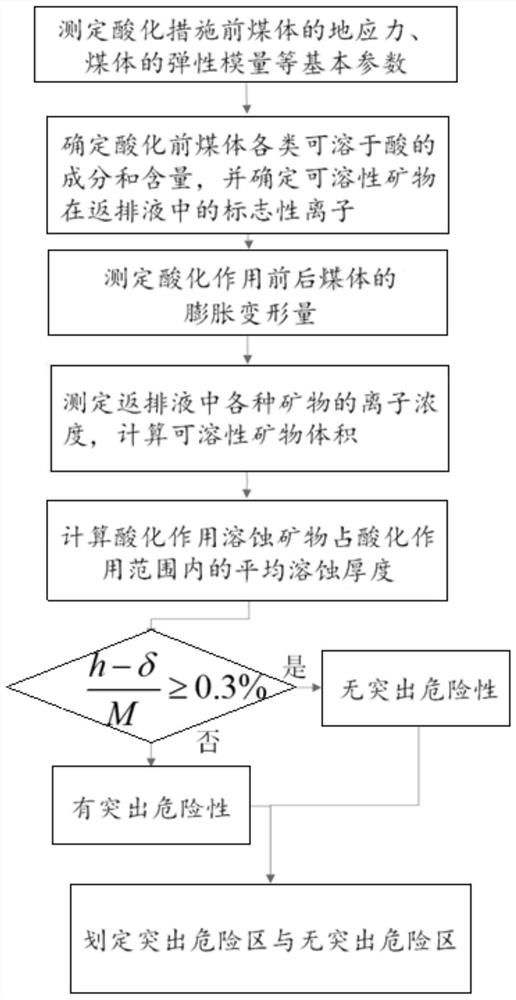

[0031] see figure 1 , the present embodiment provides a method for judging the effect of acidification and detoxification, comprising the following steps:

[0032] 1) Measure and sample the in-situ stress value of coal seam 1 in the area to be gas controlled by using the hollow inclusion borehole stress relief method. The elastic modulus test is carried out to determine the elastic modulus and Poisson's ratio parameters of the coal sample.

[0033] 2) Use X-ray diffraction and fluorescence spectroscopy to find out the types of erodible minerals that can react with acid in coal samples, and use the calibration method to determine the content of various erodible minerals. Wherein, the erodible minerals include carbonate rocks, silicate rocks and sulfides.

[0034] 3) Implement acidification and anti-permeability measures, and use the deep base point method to measure the expansion deformation δ of coal seam 1.

[0035] 3.1) Acidizing borehole 2 and coal expansion and deformat...

Embodiment 2

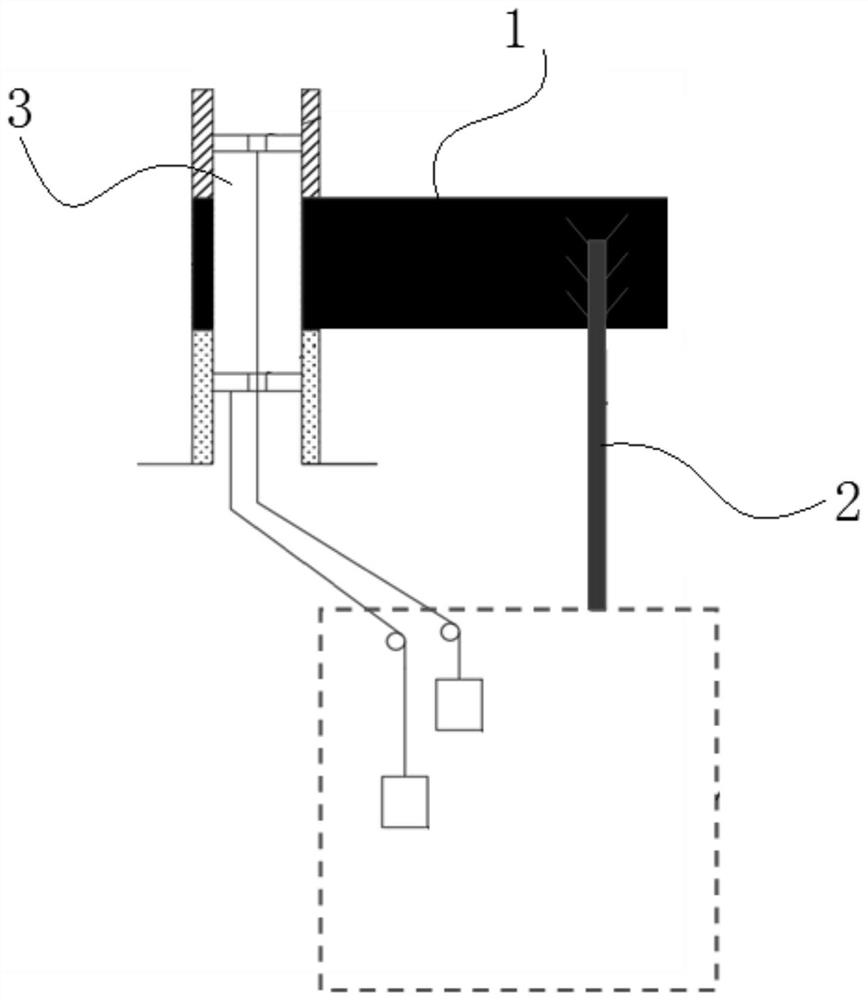

[0046] The main steps of this embodiment are the same as those in Embodiment 1. see figure 2 , Outburst elimination in this embodiment is the acidification of the upper coal seam. Acidizing borehole 2 is a layer-crossing borehole constructed in the drainage drill field.

Embodiment 3

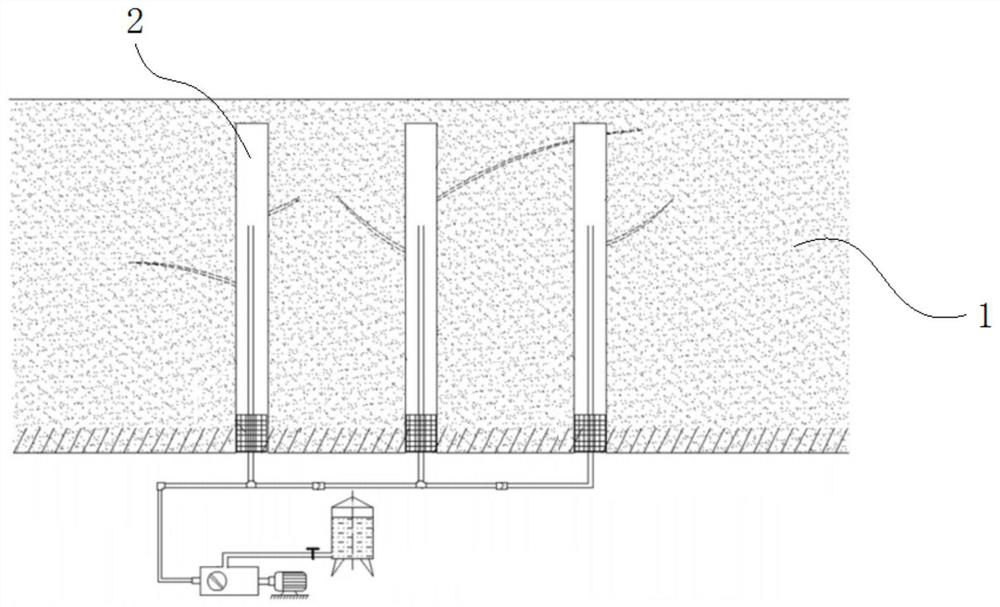

[0048] The main steps of this embodiment are the same as those in Embodiment 1. see image 3 , The work of eliminating outbursts in this embodiment is acidification and outburst elimination in this coal seam. Acidizing drilling 2 is to drill down along the coal seam inclination on the side of the roadway along the return air channel before mining at the working face, and to drill down along the inclination of the coal seam on the side of the roadway along the transport channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com