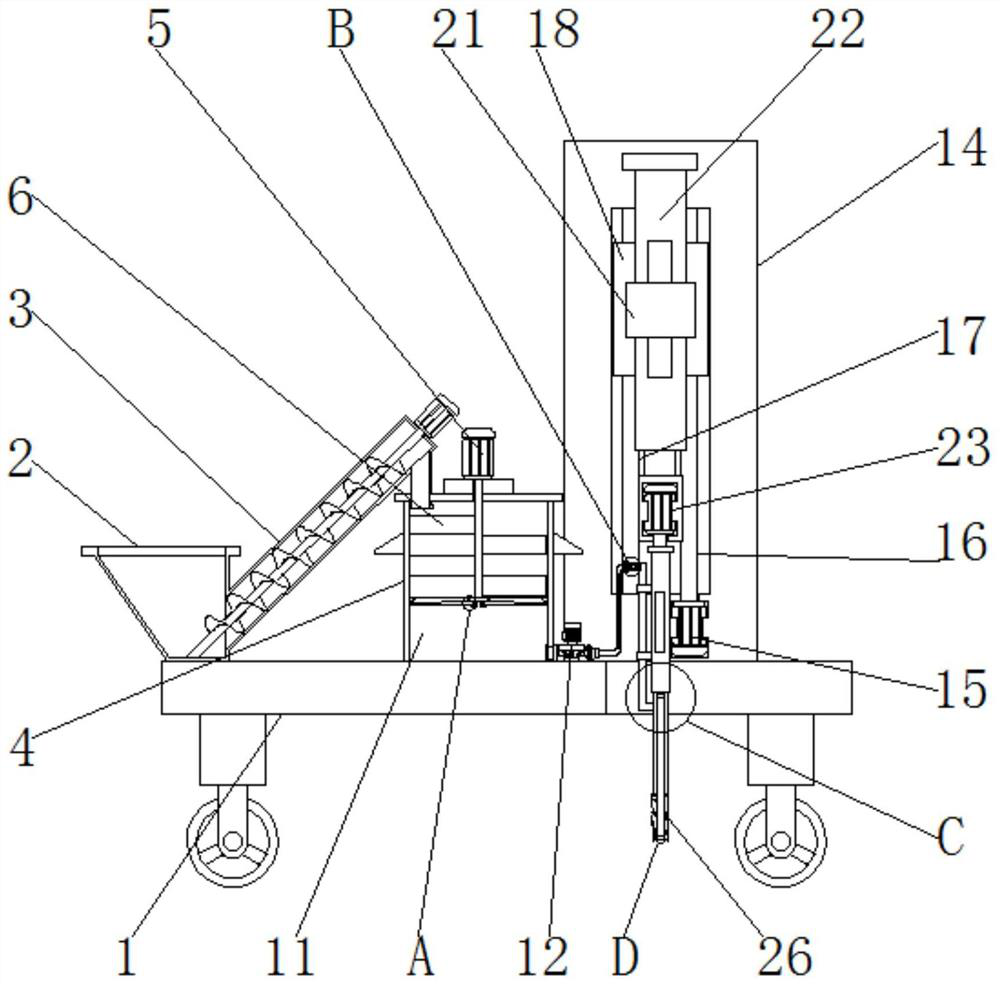

Roadbed underground grouting reinforcement device for road construction

A technology for road construction and grouting reinforcement, applied in the protection of roads, roads and soils, can solve the problems of insufficient time, inconvenient disassembly and maintenance of pipelines, unsatisfactory toughness, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

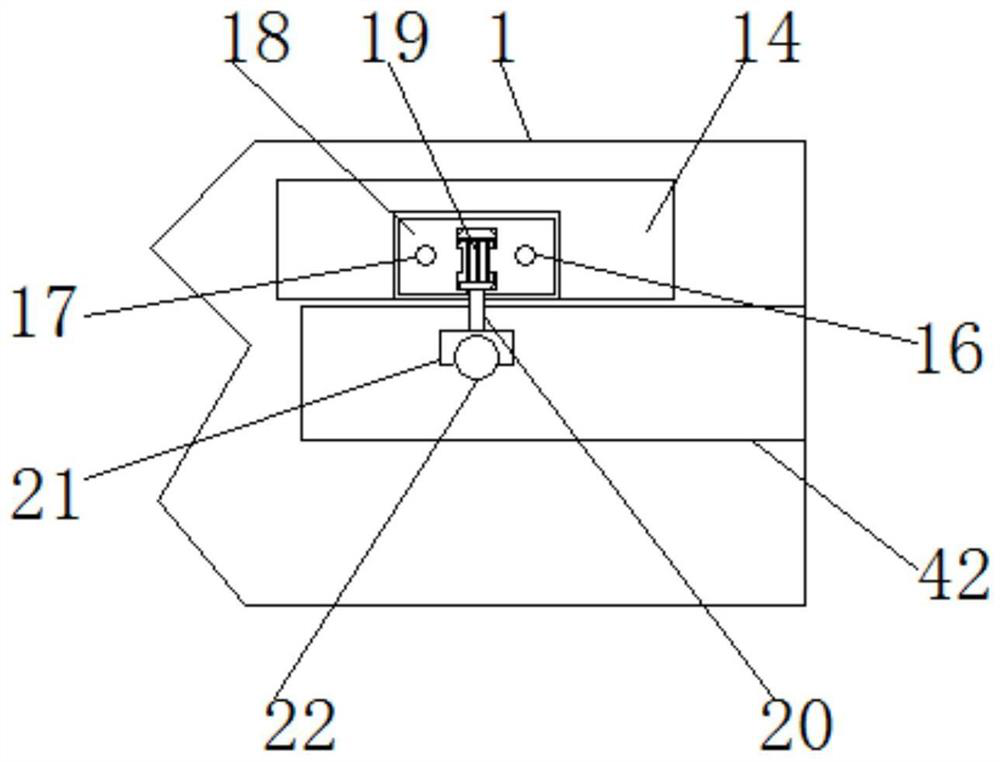

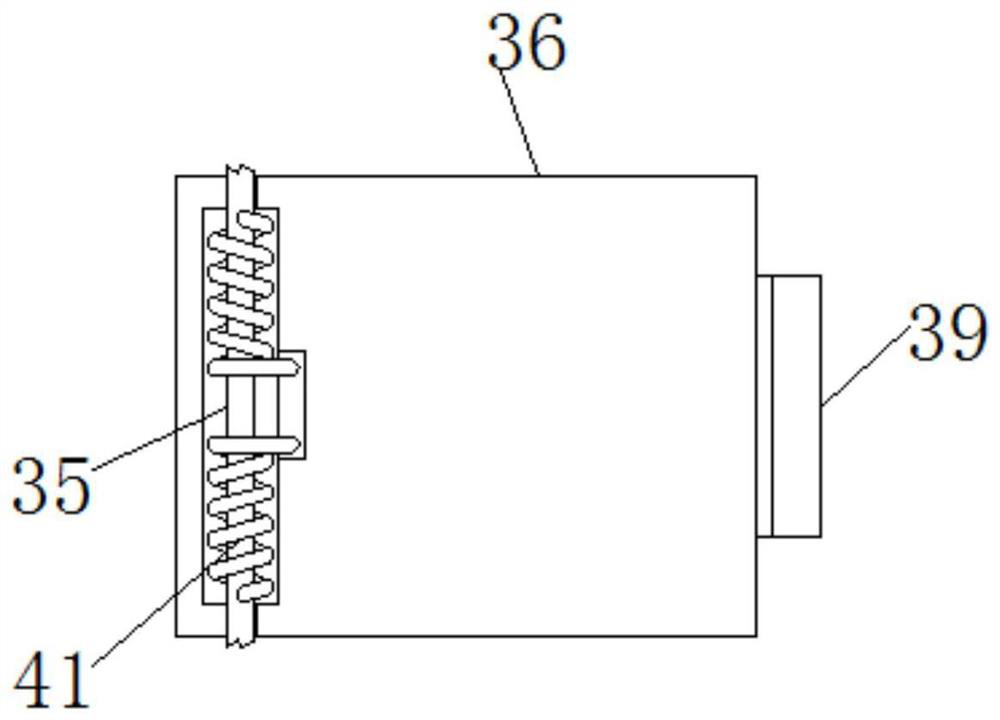

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment 1 provides a kind of epoxy grouting material, and it comprises the following components in parts by mass: 60 parts of bisphenol A type epoxy resins; 25 parts of furfuryl alcohol phenolic resins; 30 parts of ethylene glycol glycidyl ethers , 30 parts of ethylene dithiocarbonate; 15 parts of ethylenediamine, 20 parts of p-phenylenediamine; 10 parts of protein glue, 3 parts of NaOH, 3 parts of aluminum chloride, and 3 parts of glyoxal.

Embodiment 2

[0059] Present embodiment 2 provides another kind of epoxy grouting material, and it comprises the following components in parts by mass: 50 parts of bisphenol F type epoxy resins; 20 parts of furfuryl alcohol urea-formaldehyde resins; Glycerin glycidyl ether 30 parts, 20 parts of ethylene dithiocarbonate; 10 parts of ethylenediamine, 10 parts of m-phenylenediamine; 5 parts of protein glue, 2 parts of NaOH, 1 part of zinc chloride, and 2 parts of glutaraldehyde.

Embodiment 3

[0061] Present embodiment 3 provides another kind of epoxy grouting material, and it comprises the following components in parts by mass: 70 parts of bisphenol A type epoxy resins; 30 parts of furfuryl alcohol phenolic resins; Trimethylol propane glycidyl ether 50 parts, 50 parts of ethylene dithiocarbonate; 15 parts of ethylenediamine, 30 parts of p-phenylenediamine; 10 parts of protein glue, 5 parts of NaOH, 5 parts of magnesium sulfate, and 5 parts of glyoxal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com