Nanometer rare earth composite polymerization inhibitor as well as preparation method and application thereof

A composite polymerization inhibitor and nano-rare earth technology, which is applied in the fields of corrosion treatment/scaling inhibition of equipment, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problems of ineffective prolongation of oil refining and hydrogenation units, poor scale inhibition and descaling effects, etc. problem, achieve the effect of maintaining long-term operation, saving production cost and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: a kind of nano-rare earth composite polymerization inhibitor, each component and its corresponding weight are as shown in table 1, and prepare and obtain by following steps:

[0059] S1, N,N-dimethylformamide, 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide free radical, antioxidant, calcium dodecylbenzenesulfonate, nano rare earth The oxide and nano-rare earth derivatives were mixed for 20 minutes at a temperature of 30°C to obtain a mixture;

[0060] S2, adding JM-1 fuel booster to the mixture, and mixing at a temperature of 50° C. for 40 minutes to obtain a nanometer rare earth composite polymerization inhibitor.

[0061] Wherein, antioxidant adopts 2,6-di-tert-butyl p-cresol;

[0062] Nanometer rare earth oxide adopts nanometer lanthanum oxide;

[0063] Lanthanum chloride is used for nano-rare earth derivatives;

[0064] The nano rare earth oxide and the nano rare earth derivative are composed of nano lanthanum oxide and lanthanum chloride in a we...

Embodiment 2-6

[0066] Embodiment 2-6: A kind of nano-rare earth composite polymerization inhibitor, the difference from Embodiment 1 is that each component and its corresponding weight are shown in Table 1.

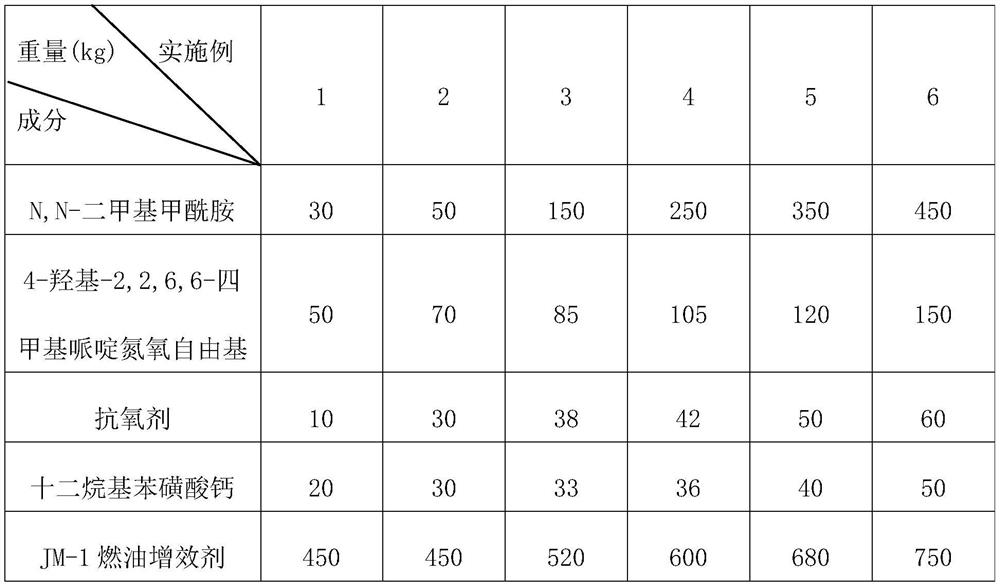

[0067] Each component and its weight (kg) in table 1 embodiment 1-6

[0068]

Embodiment 7

[0069] Embodiment 7: a kind of nano-rare earth composite polymerization inhibitor, the difference with embodiment 4 is, in the preparation process of nano-rare earth composite polymerization inhibitor, antioxidant consists of 2,6-di-tert-butyl p-cresol and N,N'-di-sec-butyl-p-phenylenediamine is composed by mixing at a weight ratio of 1:1. Nano-rare earth oxides use nano-lanthanum oxide and nano-cerium oxide, nano-rare-earth derivatives use lanthanum chloride and cerium chloride, nano-rare-earth oxides and nano-rare earth derivatives are made of nano-lanthanum Cerium is mixed in a weight ratio of 1:1:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com