Gas separation device for geothermal energy recharge well

A gas separation and reinjection well technology, which is applied in degassed water/sewage treatment, water/sewage multi-stage treatment, mechanical oscillation water/sewage treatment, etc., can solve the waste of thermal energy area, blockage, and affect the recharge effect, etc. problems, to achieve the effects of reducing energy consumption, stabilizing the water outlet speed, and ensuring the utilization rate of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

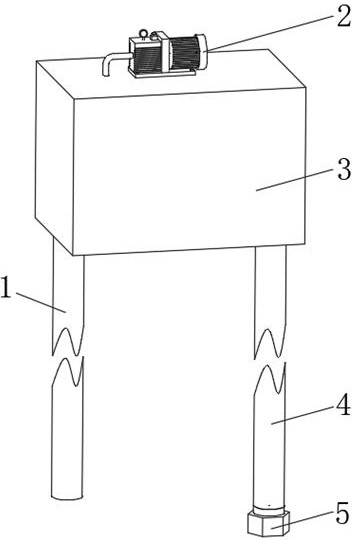

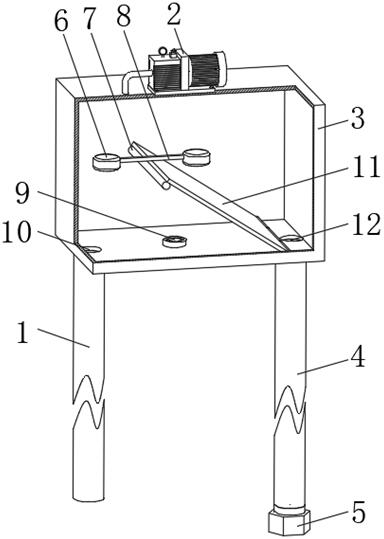

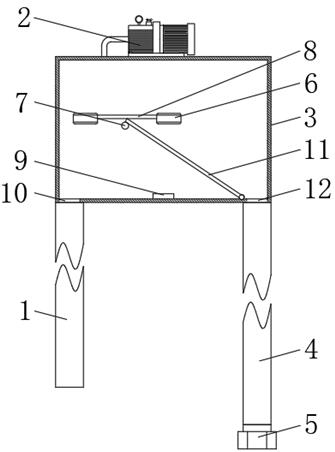

[0033] Example 1: Please refer to Figure 1-3 , this embodiment discloses a gas separation device for geothermal energy recharge wells, including a negative pressure pump 2 and a sealed housing 3, the sealed housing 3 is used to form a negative pressure environment, and the sealed housing 3 can withstand the difference in internal and external air pressure; The upper side of the casing 3 is provided with an exhaust hole communicating with the inside and outside thereof, and the exhaust hole communicates with the air inlet of the negative pressure pump 2 .

[0034] Specifically, such as figure 2 As shown, the lower side of the sealed housing 3 is provided with a water inlet hole 10 and a water outlet hole 12 that communicate with the inside and outside of the water inlet hole 10. connect.

[0035] Further, the height difference between the bottom end of the drain pipe 4 and the upper side of the inner cavity of the sealed housing 3 is greater than 10m.

[0036] The negative...

Embodiment 2

[0049] Embodiment two: if figure 2As shown, this embodiment discloses a gas separation device for geothermal energy reinjection wells. The bottom side of the inner cavity of the sealed housing 3 is connected to the rotating shaft or hinge at the lower end of the rotating plate 11. The rotating plate 11 is located between the water inlet hole 10 and the water outlet hole 12. A floating member is installed on the upper end of the rotating plate 11. The width of the rotating plate 11 is Both sides of the direction are slidingly connected with the inner wall of the sealed casing 3 , and the recharge water in the sealed casing 3 flows through the top of the rotating plate 11 .

[0050] When the sealing shell 3 is filled with refilling water, the refilling water will cause the floating part to float up, and the floating part will drive the upper end of the rotating plate 11 to move, and the distance between the bottom end of the rotating plate 11 and the liquid surface in the seali...

Embodiment 3

[0053] Embodiment three: as figure 2 and image 3 As shown, this embodiment discloses a gas separation device for geothermal energy recharge wells. On the basis of Embodiment 1 or Embodiment 2, an ultraviolet lamp 7 is installed in the sealed casing 3 of this embodiment; The cables pass through the sealed casing 3 and are electrically connected to the controller outside the sealed casing 3 .

[0054] The ultraviolet lamp 7 sterilizes the water flowing through the sealed casing 3 to prevent bacteria from corroding the pipeline or blocking the gaps in the heat storage area.

[0055] Iron bacteria: A group of bacteria that derive their energy from the oxidation of ferrous iron. The ferric hydroxide formed can be stored inside or outside the bacterial membrane sheath and can corrode pipes.

[0056] Saprophytic bacteria: They are "heterotrophic" bacteria. Under certain conditions, they obtain energy from organic matter, produce viscous substances, and accumulate and precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com