Spiral conveyor

A technology of screw conveyor and screw body, which is applied in the field of feeding machinery and equipment, can solve the problems of easy damage of tail bearings, and achieve the effects of protecting the contact surface, good self-lubricating effect, and good self-lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

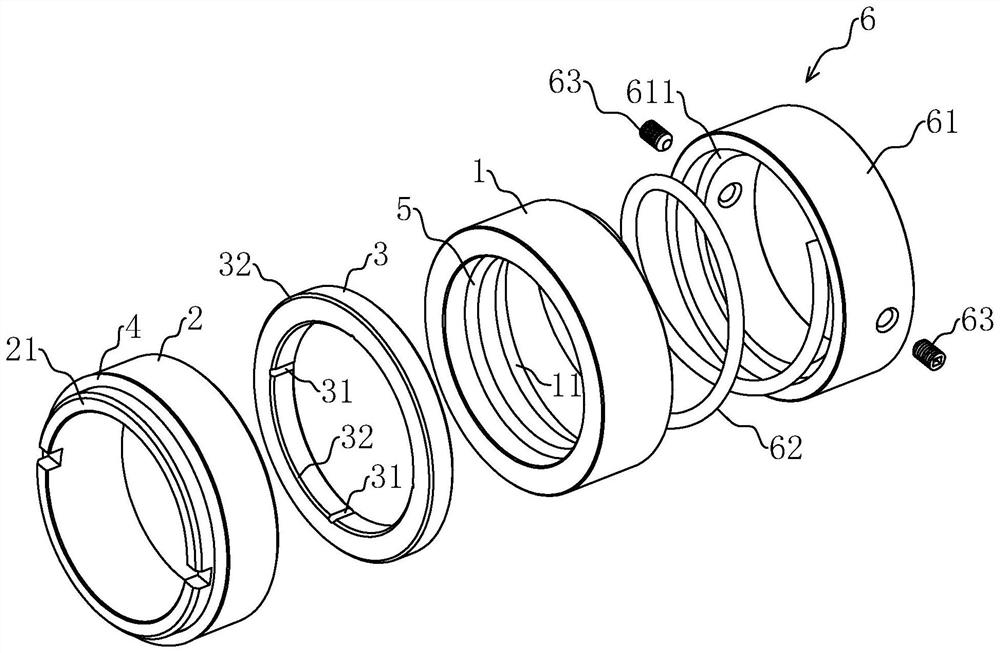

[0038] The following is attached Figure 1-4 The application is described in further detail.

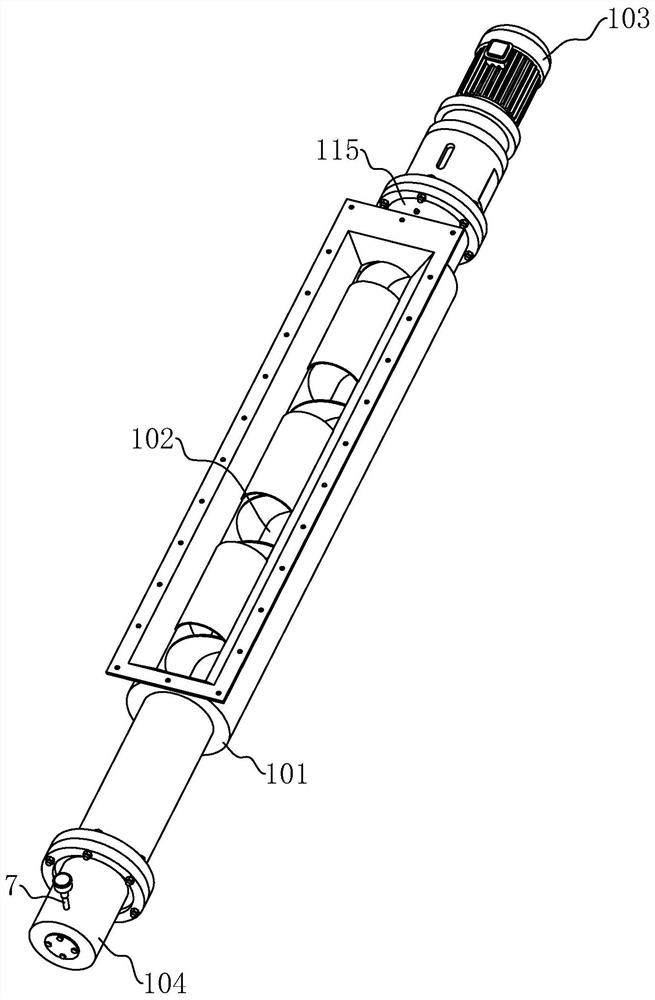

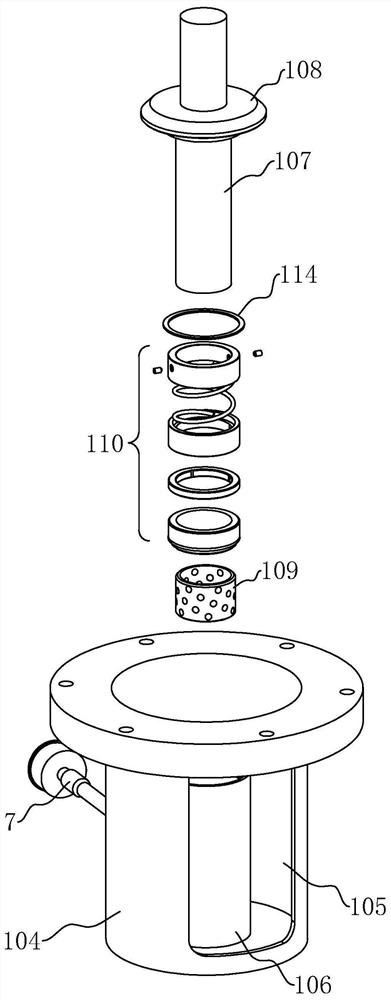

[0039] The embodiment of the present application discloses a screw conveyor, which is suitable for harsh environments with medium and low speed rotation. refer to figure 1 with figure 2 , the screw conveyor includes: a main casing 101, a screw body 102 and a power source 103, the screw body 102 is rotatably installed in the main casing 101 and its two ends protrude from the two ends of the main casing 101, and one end of the screw body 102 is connected with the power source 103 , the power source 103 drives the screw body 102 to rotate, the power source 103 is specifically a driving motor, and the screw body 102 is specifically composed of a cylindrical shaft and a helical blade spirally arranged on the outer peripheral wall of the cylindrical shaft.

[0040] The end of the main casing 101 away from the power source 103 is fixedly installed with a tail casing 104, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com