A kind of trash can and cleaning and drying method thereof

A technology of trash cans and barrels, applied in the field of trash cans, can solve the problems of affecting garbage disposal, inconvenience of taking out garbage, and high labor costs, so as to ensure the effect and area of wetting, improve the efficiency and effect of cleaning, and improve the moistening effect. The effect of wet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

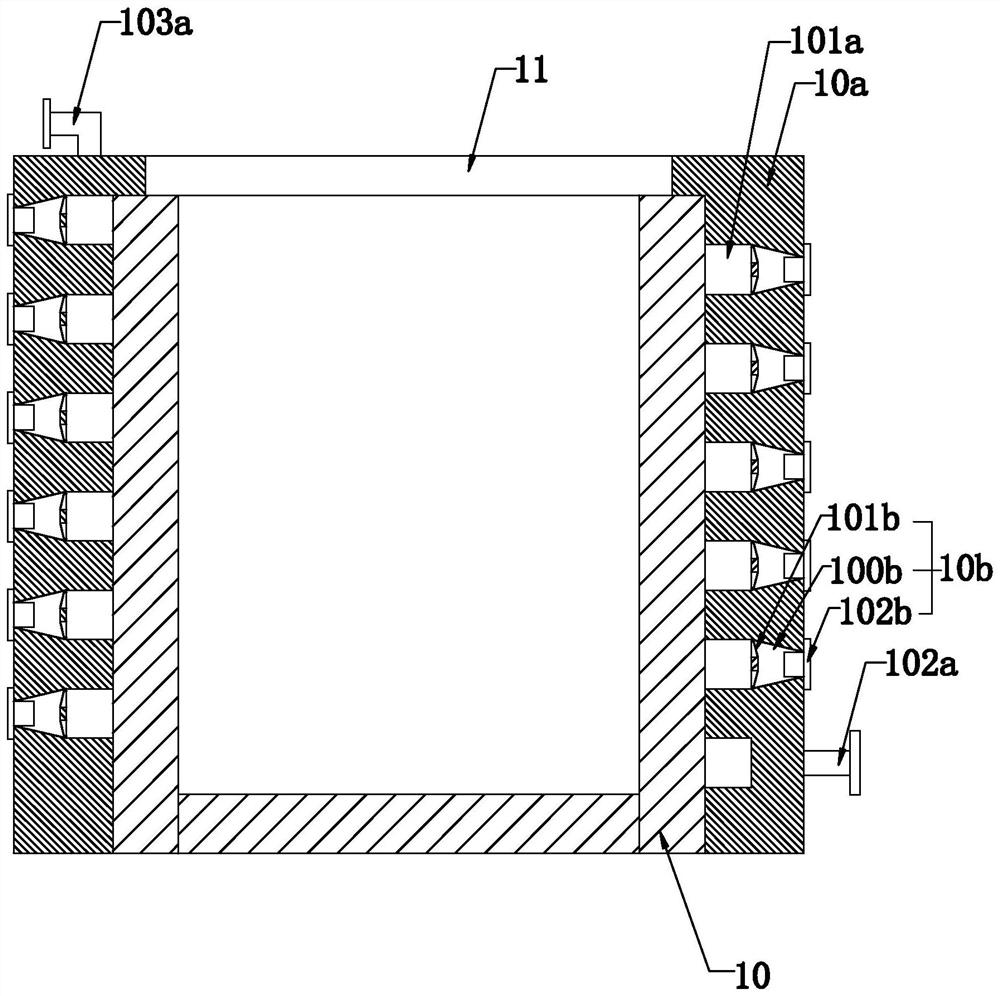

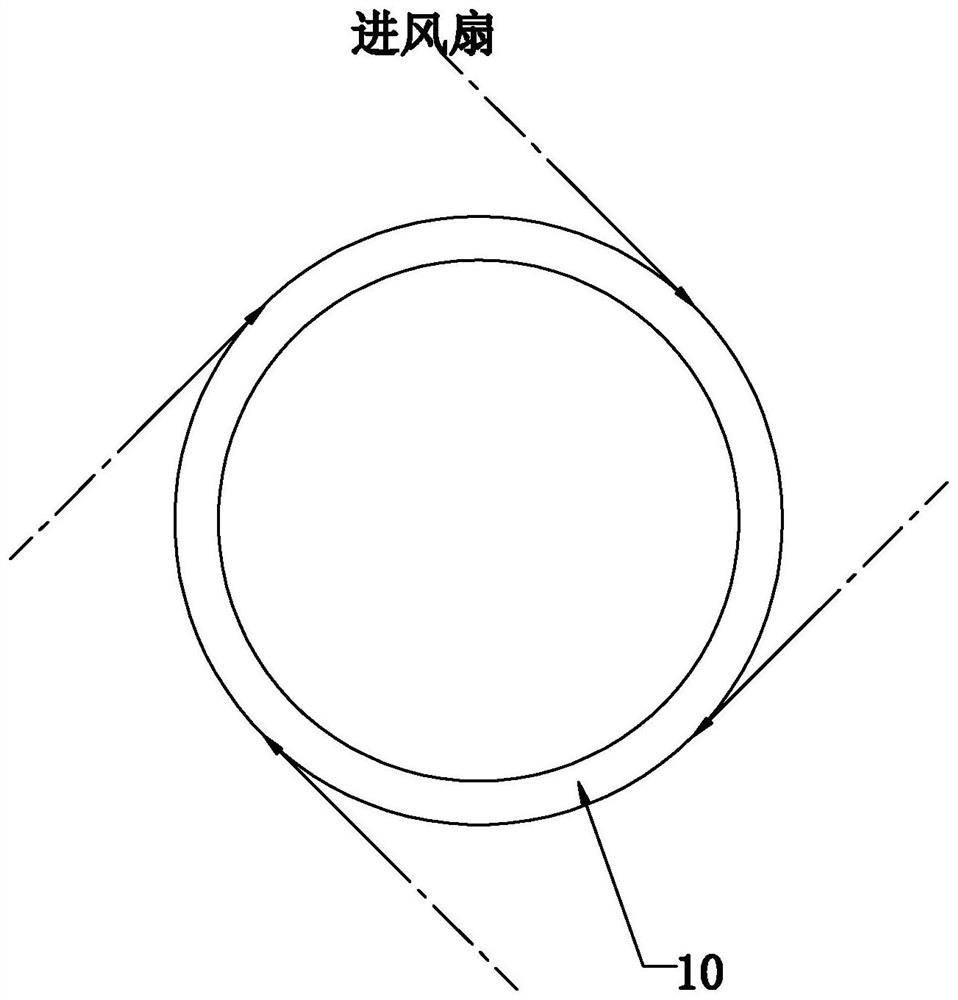

[0047] like Figure 1 - Figure 2 As shown, the present invention provides a trash can, including a bucket 10, and a barrel cover 11 mounted at the top of the bucket 10, in the specific embodiment of the present invention, including a bucket having a bucket 10; The outer barrel includes a hull body 10a having a chamber having a compatible chamber with the bucket 10, which is formed on the wall of the outer wall of the outer barrel body 10a and a helical extending heat exchange groove 101a, which is provided. The barrel body 10a and the air intake port 102a and the air opening 103a communicating with the transfer tank 101a and a plurality of spaced spaces 101a and the air in the heat exchange tank 101a toward the outer wall of the barrel 10 The flush module 10b guided in the direction; wherein the fluid module 10b includes an opening 100B disposed on the outer barrel body 10a and a fitting fan 101b attached to the opening 100b, and in the opening. A closure cover 102b is provided wit...

Embodiment 2

[0050] Example 2 The difference between the embodiment 1 is

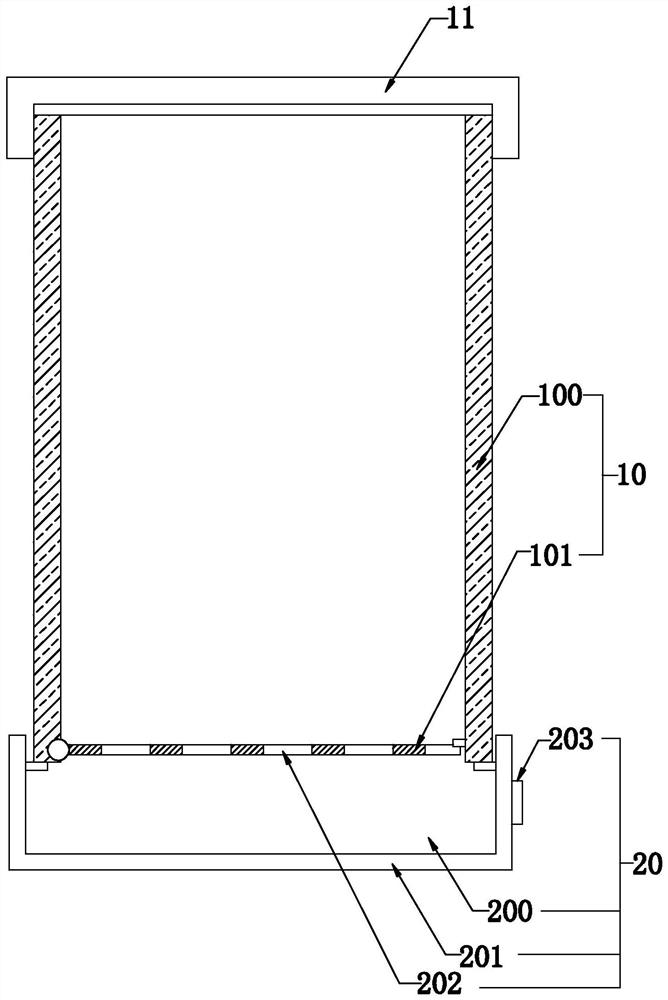

[0051] like image 3 As shown in the specific embodiment of the present invention, the bucket 10 includes an upper end and the lower end, and the lower end is provided and provided at the lower end opening of the body 100 and any side and the body 100 hinges and at least one side. A support plate 101 that is detachably coupled to the body 100; when the support plate 101 is flipped with the body 100 hinges and open the opening of the lower end of the body 100, the underbody 100 can pass through the lower end of the body 100. The opening is discharged.

[0052] In a particular embodiment of the invention, it is also included in the bottom portion of the body 100 and is used to support the drain structure 20 of the body 100; wherein the drainage structure 20 includes a recess 200 and a base 201 for supporting the body 100. The drain hole 202 is provided on the support plate 101 and an exhaust source 203 mounted on the base ...

Embodiment 3

[0057] Example 3, the same embodiment is:

[0058] like Figure 4 - Figure 10 As shown in the specific embodiments of the present invention, it is also included in the storage body 30 mounted on the body 100 and a cleaning device mounted on the tub cover 11 and by water storage body 30; wherein the cleaning device comprises At least three turning on the tub 11 and the drive wheel 310 driven by the motor 311 by the motor 311, the transmission wheel 310 driven by the motor 311, and several mounted The water supply portion 313, which is attached to the synchronous transmission belt 312 and is located between the adjacent transmission wheel 310 and is mounted on the tub 11 and is used to simultaneously provide water supply portion 314 to each watering device 313; wherein the water supply Part 314 includes a water pump 3140 mounted on the tub 11 and a water supply pipe 315 for delivering water in the water storage body 30 to the input of the water spray device 313.

[0059] In a particu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com