A kind of hub motor drive vehicle suspension system

An in-wheel motor and automobile suspension technology, applied in the field of vehicles, can solve the problems affecting comfort, driving smoothness and control stability, increasing the unsprung mass of the car and the moment of inertia of the wheel hub, poor heat dissipation conditions of the in-wheel motor, etc. The inner space of the hub, the possibility of large space, the effect of improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

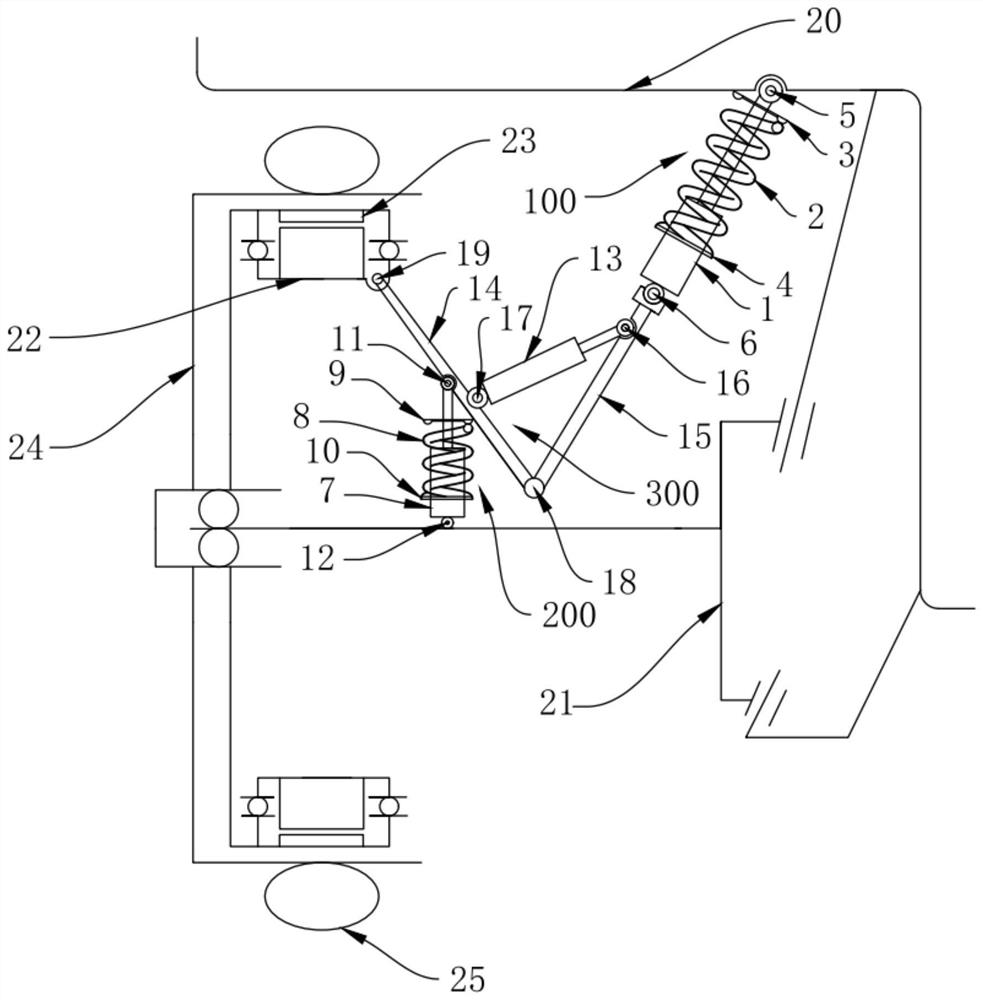

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] In the wheel hub motor-driven automobile suspension system of the embodiment of the present invention, the main suspension system 100 includes a shock absorber A1, a spring A2, an upper support A3 and a lower support A4, an upper lifting lug A5 and a lower lifting lug A6, and the shock absorber A1 is hinged on the vehicle body 20 through the upper lug A5, and the other end of the shock absorber A1 is connected with the rod B15 through the lower lug A6. The spring A2 is sleeved on the shock absorber A1 through the upper support A3 and the lower support A4. The V-shaped link mechanism 300 includes a connecting rod A14 and a connecting rod B15 , the other end of the connecting rod B15 is connected to the connecting rod A14 through a rotatable pivot point 18 , and the other end of the connecting rod A14 is hinged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com