High-stability pipe welder set

A high-stability, welded pipe technology, applied in the field of metal pipe diameter reduction, can solve problems such as vertical roll offset and shaking, upturning or sideways, stability requirements, etc., to improve utilization efficiency, increase utilization rate, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

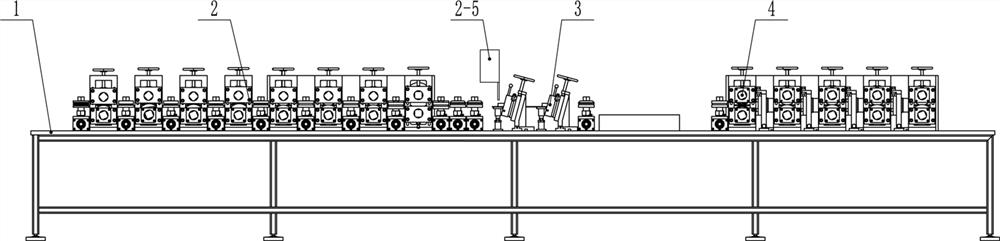

[0041] like figure 1 As shown, a high-stability welded pipe unit includes a platform 1 and a welded pipe unit 2, a deburring mechanism 3, and a diameter reducing unit 4 sequentially arranged on the platform;

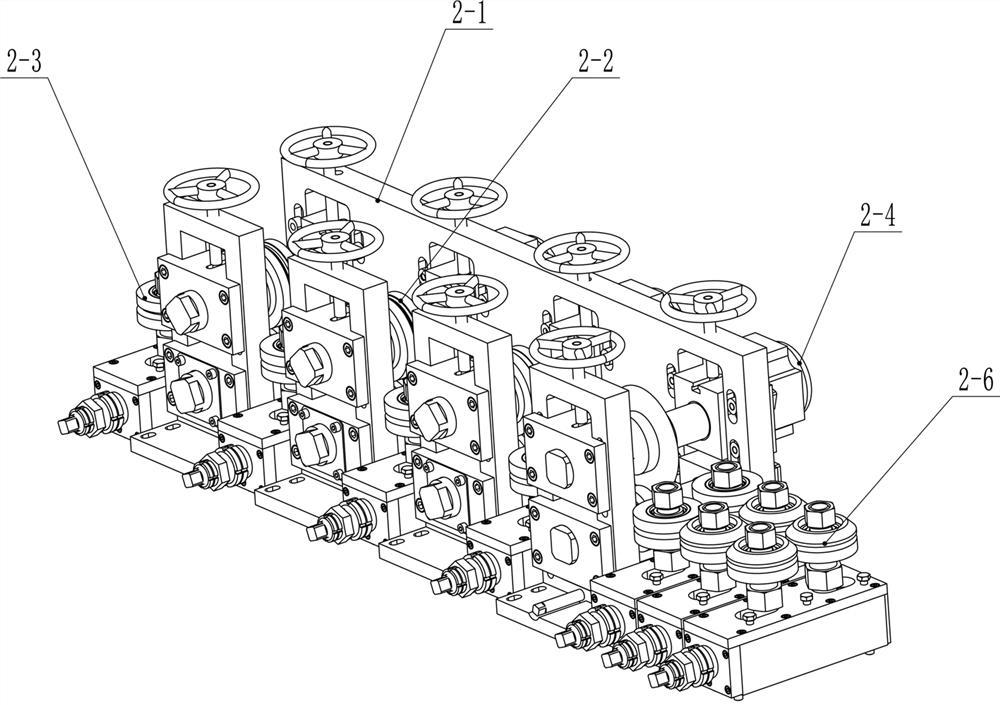

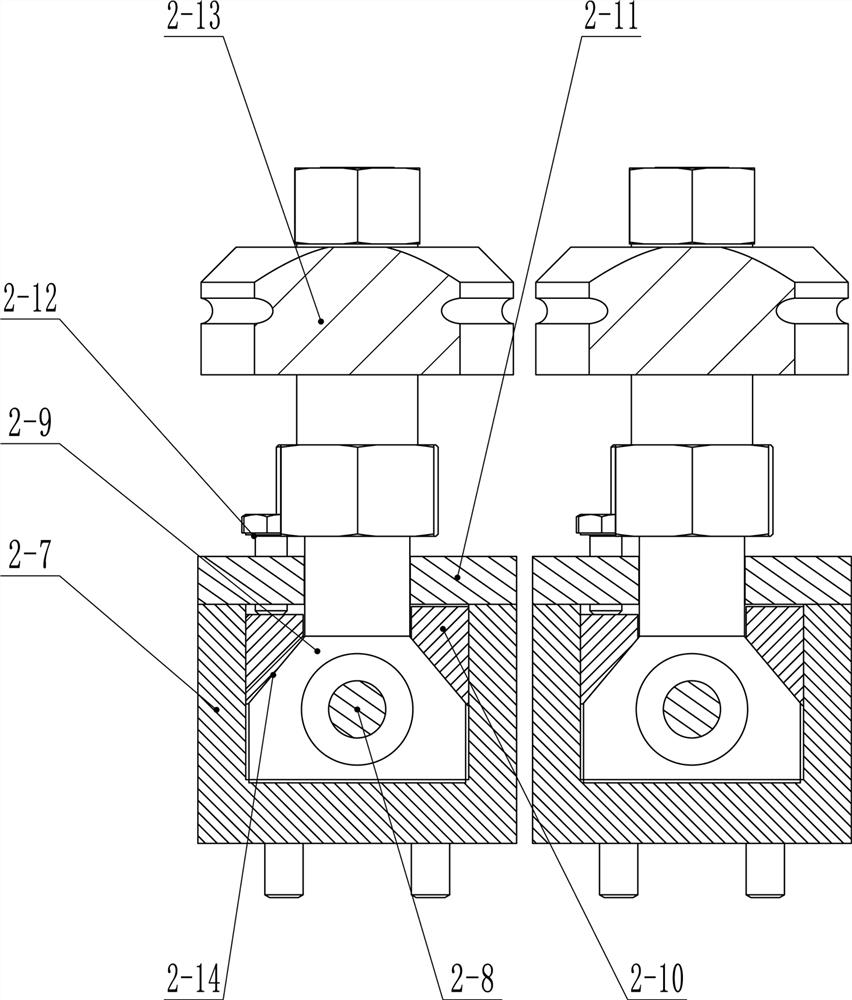

[0042] like figure 2 and image 3As shown, the welded pipe unit 2 includes a welded pipe archway 2-1, several forming roller groups 2-2, several vertical roller roller groups 2-3, several forming gear motors 2-4, welded pipe machine 2-5 and vertical roller output rollers Group 2-6, the welded pipe archway 2-1 is fixed on the platform 1 in two rows facing each other, several forming roller groups 2-2 are sequentially installed on the welded pipe archway, and the forming gear motor 2-4 Drive the forming roller group 2-2 to rotate, the pipe welding machine 2-5 is arranged at the tail end of the forming roller group 2-3, and the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com