Beef ball making device for food processing

A technology of food processing and production equipment, which is applied in the direction of processed meat, meat processing equipment, applications, etc., can solve the problems of affecting the use of machines and the inability to clean minced beef in time, so as to improve the taste of food and improve the quality of crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

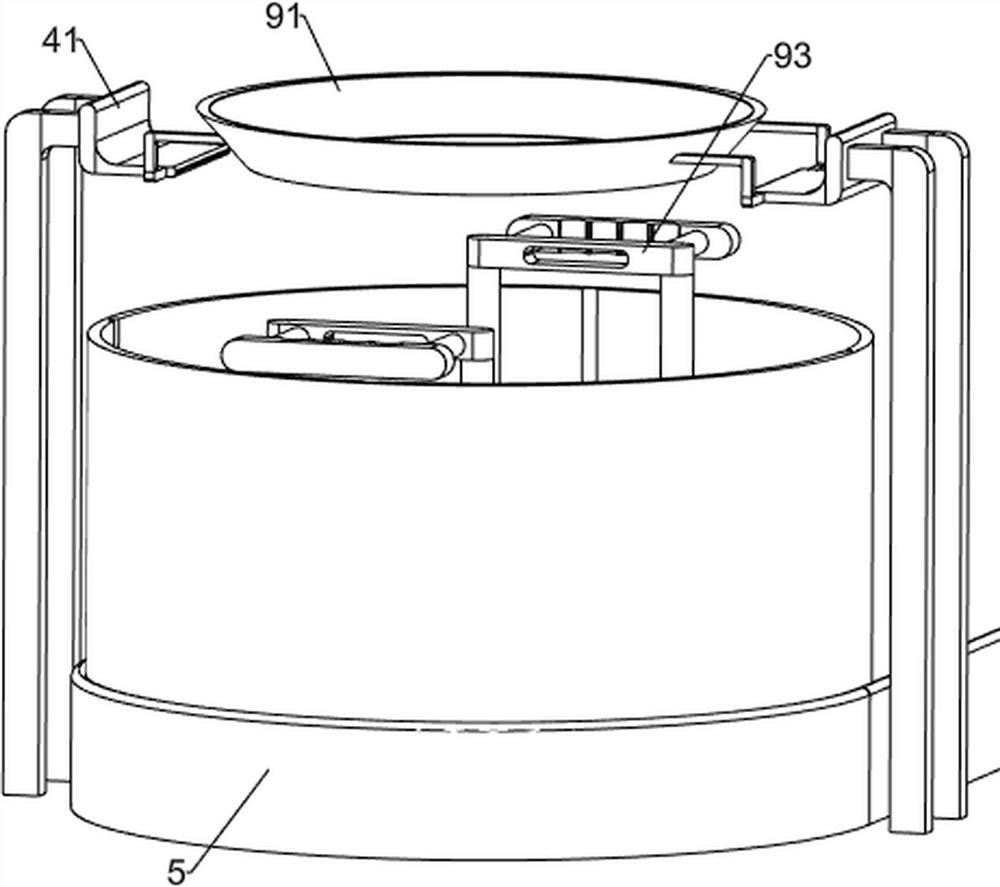

[0053] A kind of making device of beef ball for food processing, such as figure 1 , figure 2 with Figure 9 As shown, it includes a base 1, a support seat 2, a minced meat stirring mechanism 3, a meatball cutting mechanism 4, and a hot water storage bucket 5. Mechanism 3, the minced meat stirring mechanism 3 is connected with a meatball cutting mechanism 4, and the bottom of the base 1 is provided with a hot water placement bucket 5, and the hot water placement bucket 5 is located below the meatball cutting mechanism 4.

[0054] Minced meat stirring mechanism 3 includes feeding plate 31, mounting seat 32, servo motor 33, first rotating shaft 34, bevel gear set 35, second rotating shaft 36, working chamber 37, first minced meat cutter 38 and the second minced meat Cutter 39, mounting base 32 is provided on the left front side of the top of the support base 2, a servo motor 33 is provided on the top of the mounting base 32, a first rotating shaft 34 is connected to the output...

Embodiment 2

[0058] On the basis of Example 1, such as Figure 4 to Figure 8 Shown, also include coarsely minced meat mechanism 6, coarsely minced meat mechanism 6 includes mounting bracket 61, second sector gear 62, second rack 63, first return spring 64, pressed meat block 65 and minced meat net 66 , the rear side of the top of the support seat 2 is connected with a mounting frame 61, and the front side of the mounting frame 61 is symmetrically slidably provided with a second rack 63, and the top of the second rack 63 is connected with the mounting frame 61 with a first return spring 64, The second sector gear 62 is symmetrically arranged on the first rotating shaft 34, and the second sector gear 62 is engaged with the second rack 63 on the same side. The working cavity 37 is slidingly connected, and a minced meat net 66 is connected between the upper inner walls of the working cavity 37 , and the minced meat net 66 is located above the first minced meat cutter 38 .

[0059] The rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com