Tractor whole vehicle loading test device and test method

A test device, tractor technology, applied in the direction of measuring device, vehicle test, engine test, etc., can solve the problems of unable to reproduce the working condition of the tractor, high development cost, large investment in equipment, etc., to meet product development needs , low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

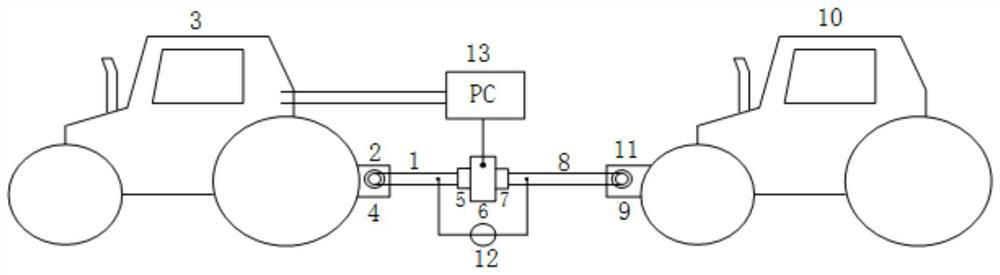

[0036] like figure 1 As shown, a tractor vehicle loading test device for loading test in the forward direction includes a power loading unit 10 , a connection measurement unit, a tractor 3 to be tested and a data acquisition unit 13 .

[0037] Wherein, the power loading unit 10 adopts a loading tractor, which applies load to the entire device according to the change of the forward working condition of the tractor 3 to be tested, so as to meet the loading requirements of the tractor 3 to be tested in changing working conditions.

[0038] The tractor 3 to be tested provides a source of driving force for the entire device, meeting the test requirements for its traction force and the like.

[0039] The connection measurement unit includes a traction force sensor 6 , a first traction rod 1 , a second traction rod 8 , a first connecting piece 2 , and a second connecting piece 11 . The first connector 2 is installed on the rear of the tractor 3 to be tested, and is hinged with one e...

Embodiment 2

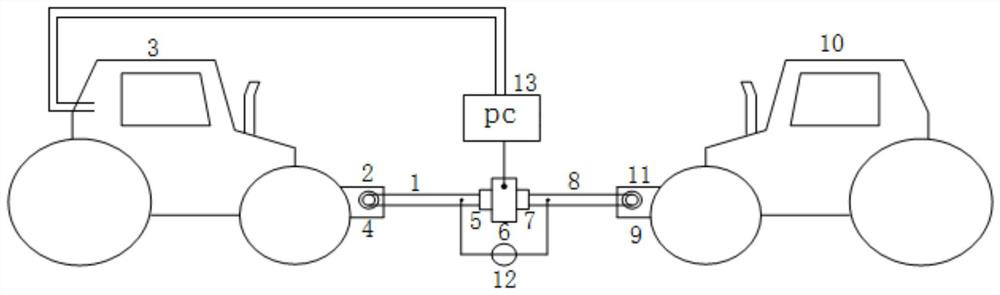

[0044] like figure 2As shown, a kind of tractor vehicle load test device for the load test in the backward direction is different from Embodiment 1 in that the first connecting piece 2 is installed on the front of the tractor 3 to be tested, and during the test, the tractor to be tested 3 sets a backward speed, and correspondingly, the loading tractor applies a load to the entire device according to the change of the backward working condition of the tractor 3 to be tested, so as to meet the loading requirements of the tractor 3 to be tested in changing working conditions. Set a forward speed to the loading tractor tractor, and this forward speed is less than the backward speed set by the tractor 3 to be measured (this forward speed is relative to the backward direction of the tractor 3 to be measured, if the second connecting member 11 is installed on the loading tractor At the rear of the vehicle, the forward speed is the speed in the forward direction of the loading tracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com