Low-grade waste heat recovery system and process of coking production system

A technology of waste heat recovery system and production system, applied in the direction of preheating, steam superheating, steam generation, etc., can solve the waste of low-temperature waste heat resources, increase energy consumption of enterprises, and fail to achieve recycling, etc., to achieve recycling and improve waste heat The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

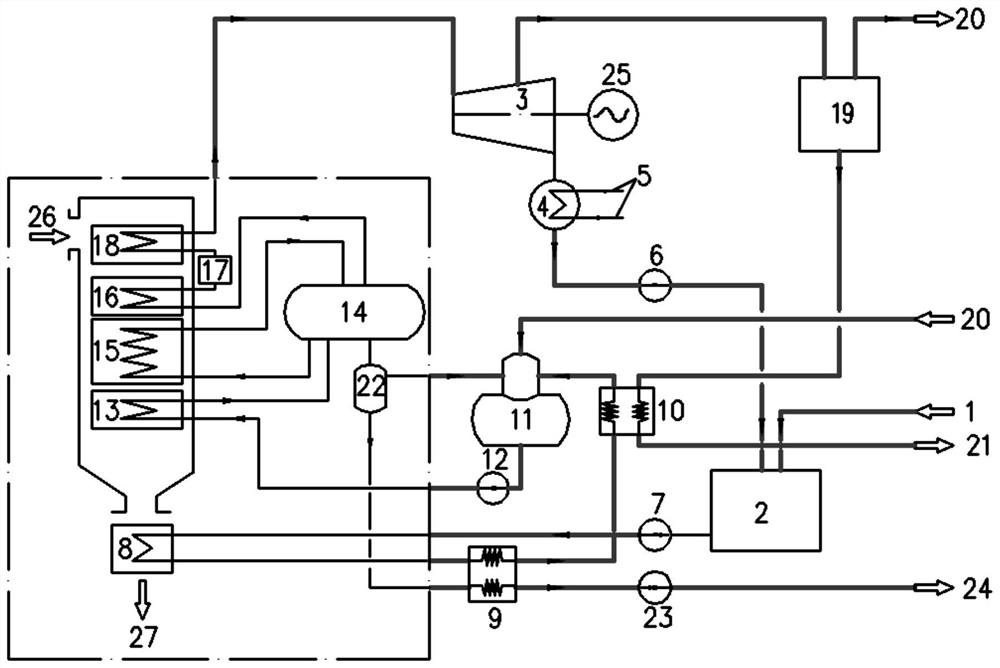

[0025] The working principle of the low-grade waste heat recovery system of a coking production system described in the present invention is:

[0026] 1) Indirect heat exchange between the condensed water in the crude benzene distillation unit and the deoxygenated return water, increase the temperature of the deoxygenated return water, save the heating steam of the deaerator, and recover the waste heat of the condensed water in the crude benzene distillation unit;

[0027] 2) The flash steam of the crude benzene distillation unit is sent to the low-pressure steam pipe network in the factory area (not limited to this method), and the waste heat of the flash steam of the crude benzene distillation unit is recovered;

[0028] 3) Indirect heat exchange between the blowdown water of the continuous blowdown expander and the deoxygenated backwater can increase the temperature of the deoxygenated backwater, save the heating steam of the deaerator, and recover the waste heat of the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com