Self-aligning roller bearing capable of adjusting clearance

A self-aligning roller bearing and clearance technology, applied in the field of bearings, can solve the problems of reducing the use effect of self-aligning roller bearings, it is difficult to improve production and processing efficiency, and the clearance cannot be adjusted, so as to improve the use stability and use effect, prevent the entry of external magazines, prevent the effect of external impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

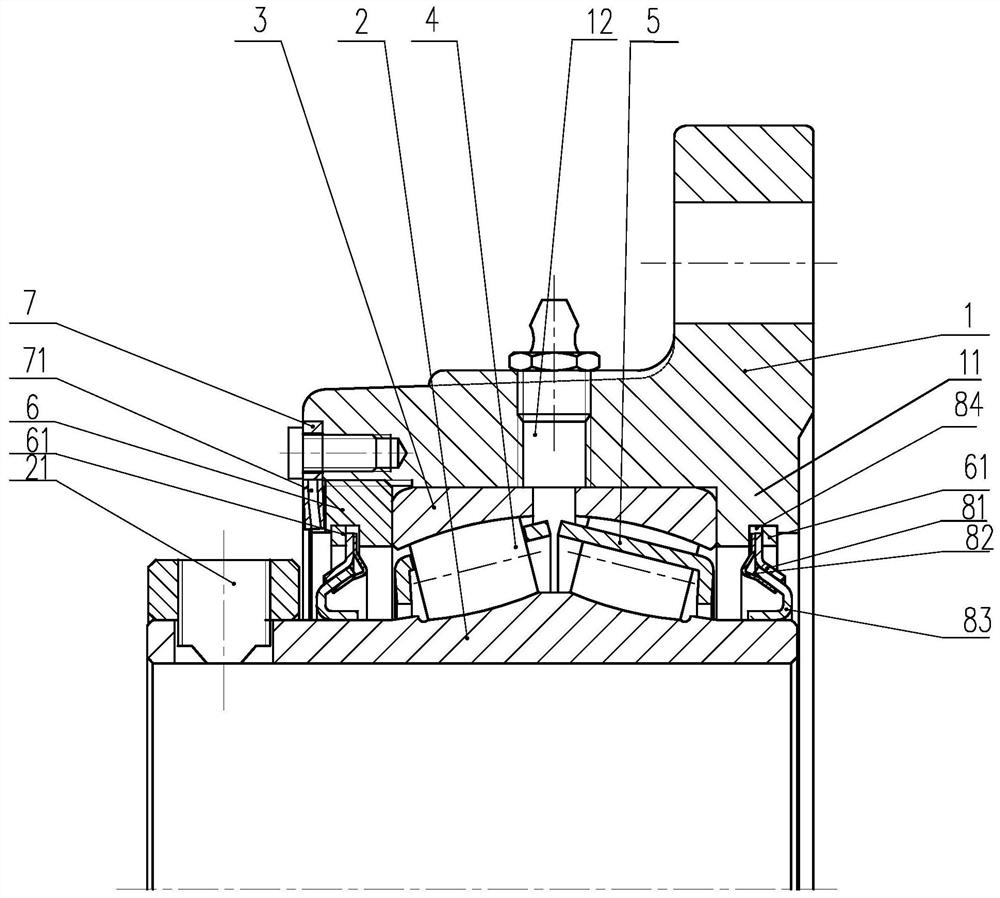

[0021] Examples of spherical roller bearings with adjustable clearance in the present invention are figure 1 As shown: it includes a bearing seat 1 and an inner ring 2 and an outer ring arranged coaxially. A positioning step 11 is formed at one end of the bearing seat 1. The outer ring is separately arranged to form two sub-outer rings 3. The two sub-outer rings 3 are Installed on the bearing seat 1, one of the sub-outer rings 3 is set in conflict with the positioning step 11, and the outer wall of the inner ring 2 is provided with raceways corresponding to the positions of the two sub-outer rings 3, and the two sub-outer rings 3 and the inner A cage 5 is arranged between the rings 2, and a roller 4 is arranged in the cage 5, and the roller 4 is rotatably matched with the raceway, and the other end of the bearing seat 1 is threaded with an adjusting retaining ring 61, so The adjustment retaining ring 61 is set against the side wall of the sub-outer ring 3, and the bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com