A wind turbine blade clearance control method based on load detection

A wind turbine and control method technology, which is applied in the directions of engine control, engine control parameters, wind turbine control, etc., can solve the problems of the adverse effect of the power generation income level of the wind turbine, the reduction of the power generation performance of the wind turbine, and the inability to accurately identify the wind rotor, etc. Achieve the effect of avoiding power generation loss, reducing application restrictions, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

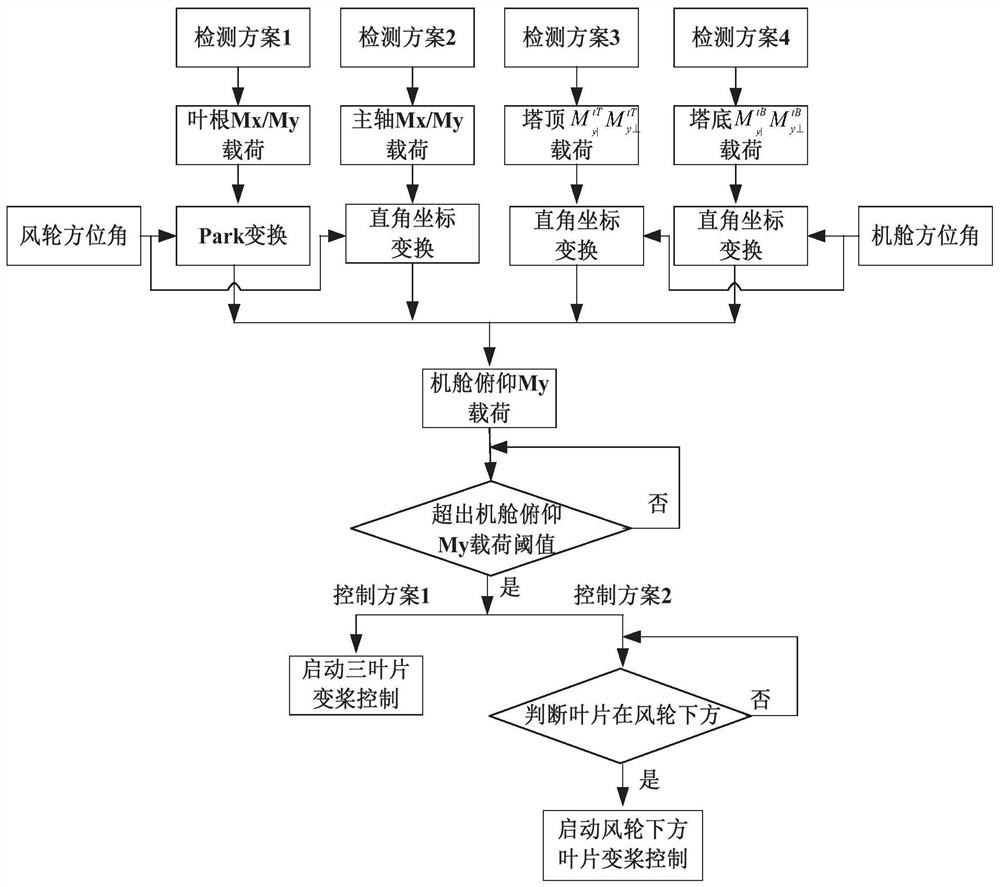

[0036] In a typical implementation of the present disclosure, such as Figure 1-Figure 4 As shown, a wind turbine blade clearance control method based on load detection is proposed.

[0037] Taking the three-blade wind turbine as an example, the following steps are included:

[0038] Select three load detection points of the blade root, the main shaft, the vertical direction of the top of the tower, and the vertical direction of the bottom of the tower to establish a load detection method for key parts;

[0039] Use sensing equipment to detect the azimuth angle of the wind wheel and nacelle yaw;

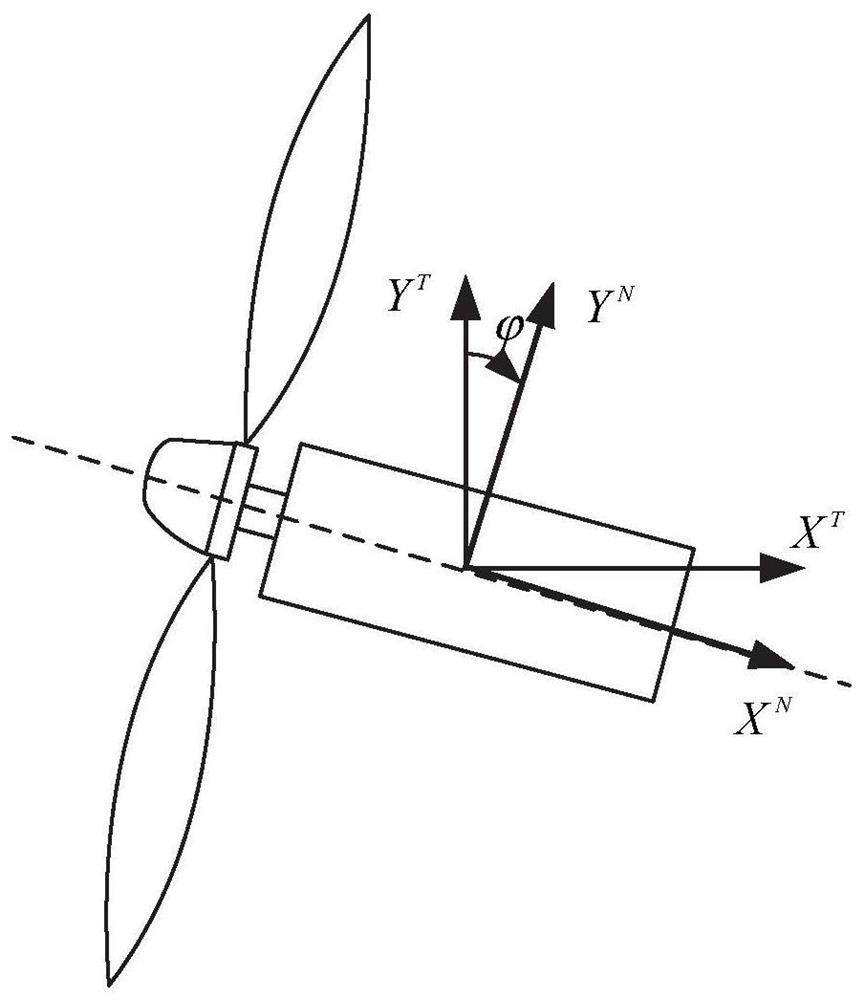

[0040] Transform the loads of key parts into the loads in the pitch direction of the nacelle in the stationary hub coordinate system;

[0041] Through the wind turbine simulation software and according to the design specifications, the negative load threshold is obtained, and the pitch protection angle is determined;

[0042] Adopt three-blade unified pitch or downwind blade indep...

Embodiment 2

[0073] In another typical implementation of the present disclosure, such as Figure 1-Figure 4 As shown, a wind turbine blade clearance control method based on load detection is proposed.

[0074] A 3.0MW wind turbine is especially suitable for high-power wind turbines with long blades. figure 1 As shown, the steps include:

[0075] (a) Select three load detection points on the blade root, the main shaft, the vertical direction of the top of the tower, and the vertical direction of the bottom of the tower. The detection methods include but are not limited to optical fiber gratings and resistive strain gauges.

[0076] (b) Use sensing devices such as encoders and proximity switches to detect the azimuth angle of the wind rotor and nacelle yaw.

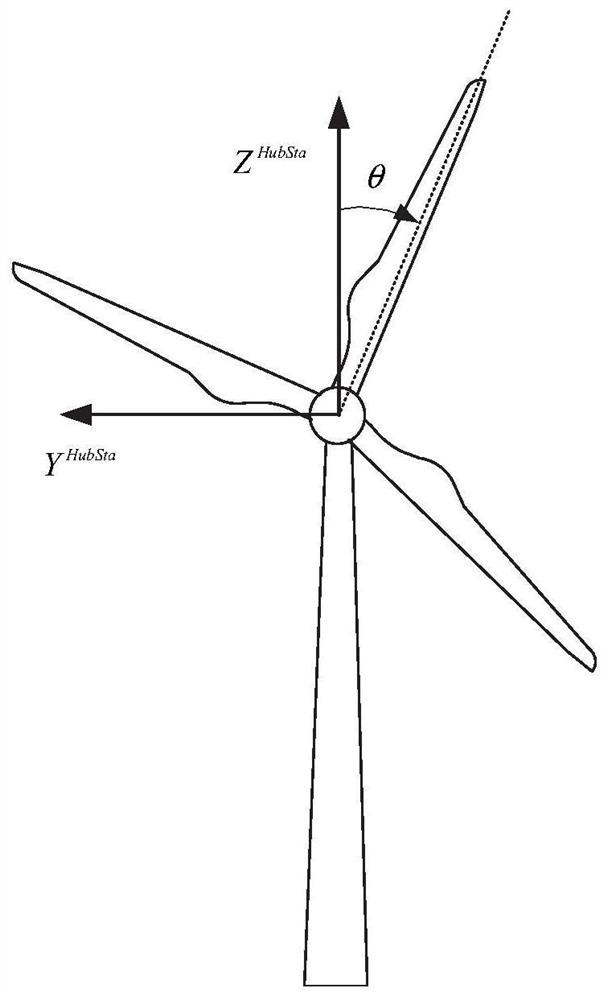

[0077] (c) For the detection scheme of the My load on the root of the three blades, the My load on the blade root of the three blades is transformed into the My load in the pitch direction of the nacelle in the static hub coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com