Coal mine fire-fighting equipment

A fire-fighting equipment and coal mine technology, applied in mining equipment, dust prevention, fire prevention, etc., can solve the problems of not being able to extinguish the fire in time, the distance between the fire point and the fire extinguishing equipment is too large, and achieve the effect of ensuring timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

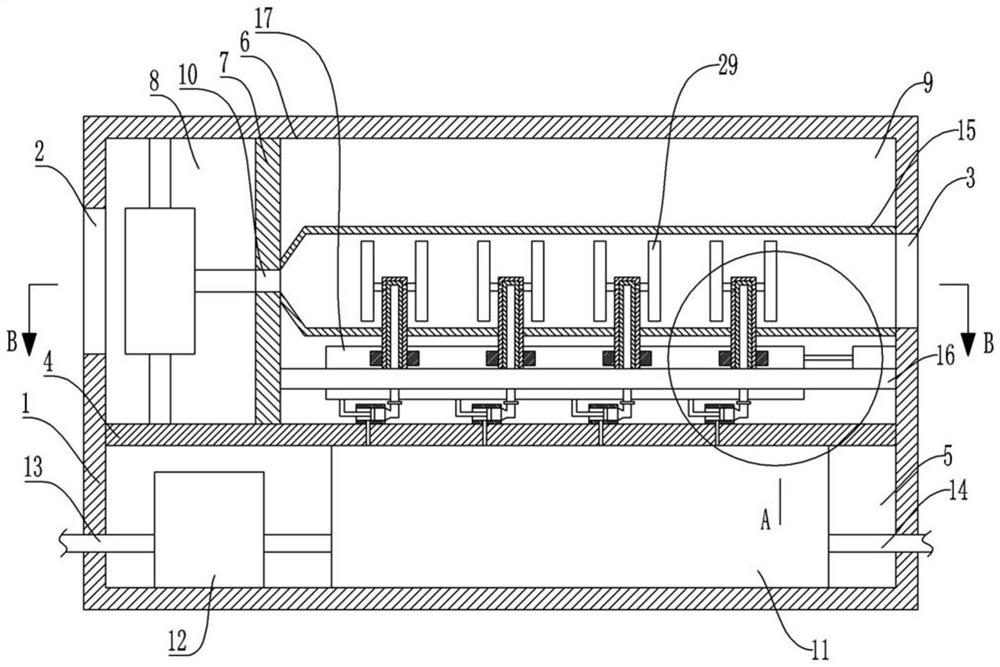

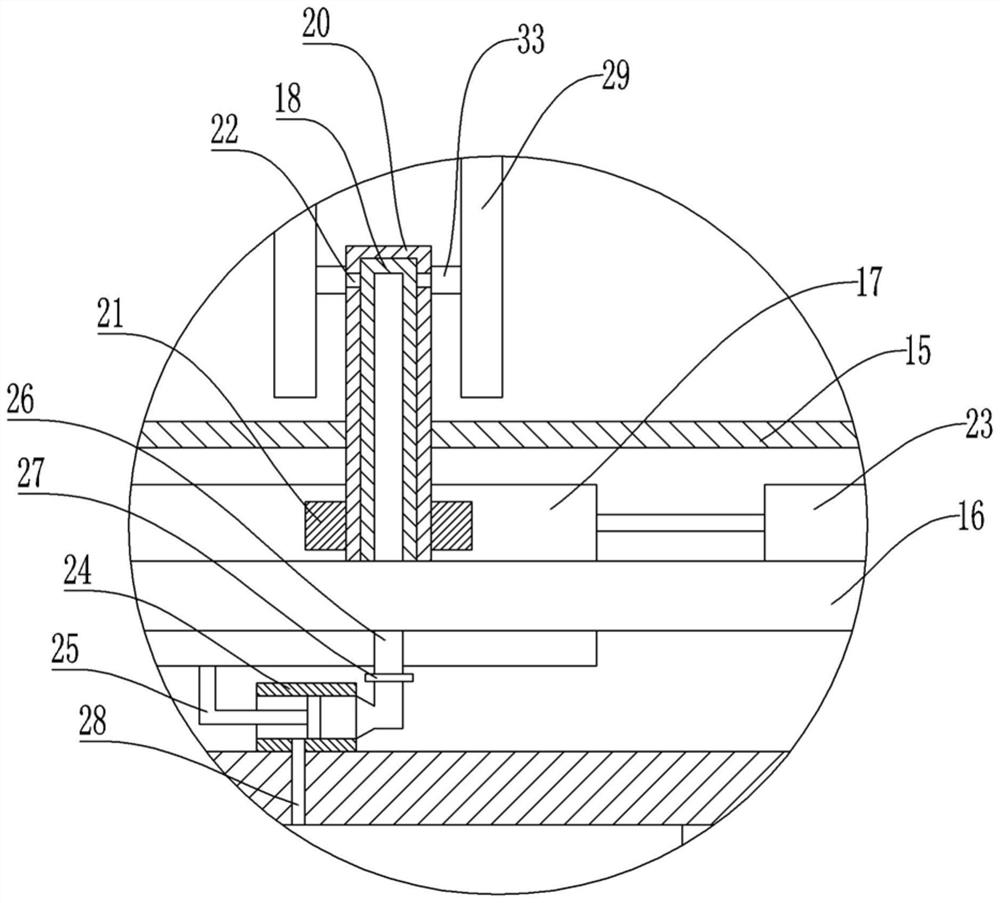

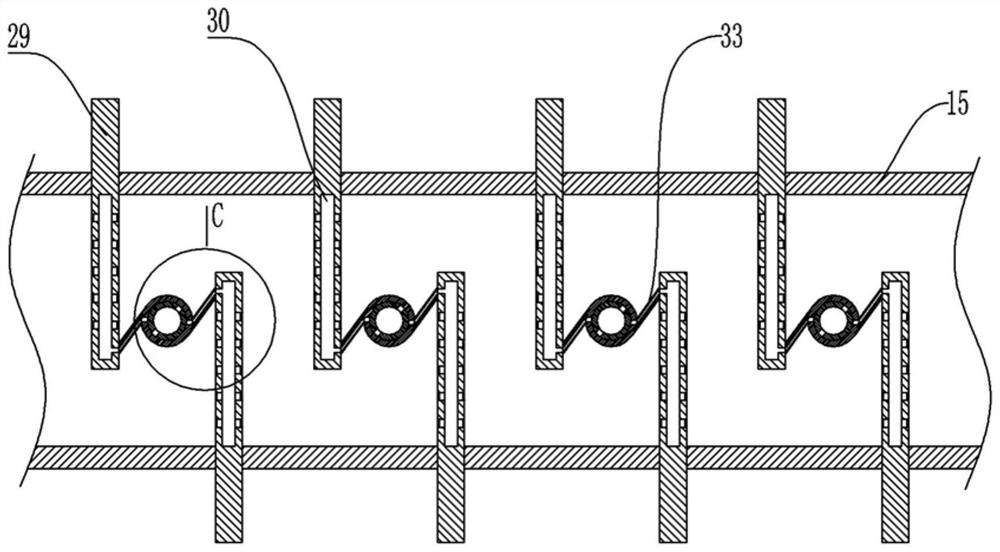

[0029] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 Shown: a coal mine fire-fighting equipment, including a box 1, the bottom of the box 1 is equipped with driving wheels, through which the box 1 is driven to move to the desired destination; the box 1 is provided with an inlet 2 and an outlet 3. A partition plate 4 is fixed horizontally in the box body 1, and the partition plate 4 divides the box body 1 into a fire protection area 5 and a dust reduction area 6; a fire protection mechanism for fire extinguishing is arranged in the fire protection area 5; the fire protection mechanism includes a fixed connection The water tank 11, the water pump 12 and the water gun 13 extending out of the box body 1 in the fire zone 5, the water pump 12 communicates with the water tank 11 and the water gun 13 respectively, and the water tank 11 is communicated with a water pipe 14 passing through the box body 1, and the water pipe 14 is threaded. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com