Feeding device

A feeding device and feeding technology, applied in the field of feeding, can solve the problem that the feed cannot be prevented from sticking to the inner wall of the feeding frame, so as to achieve the effect of increasing the feeding rate and ensuring the feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

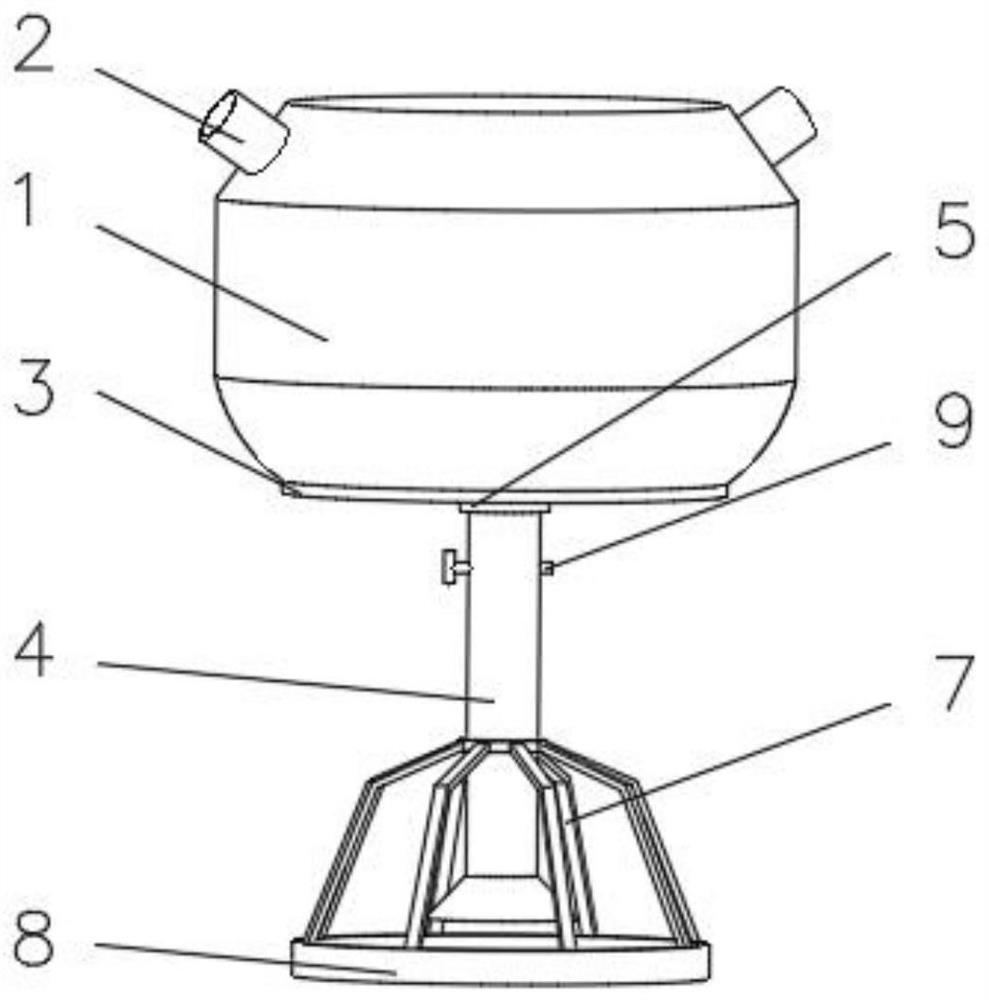

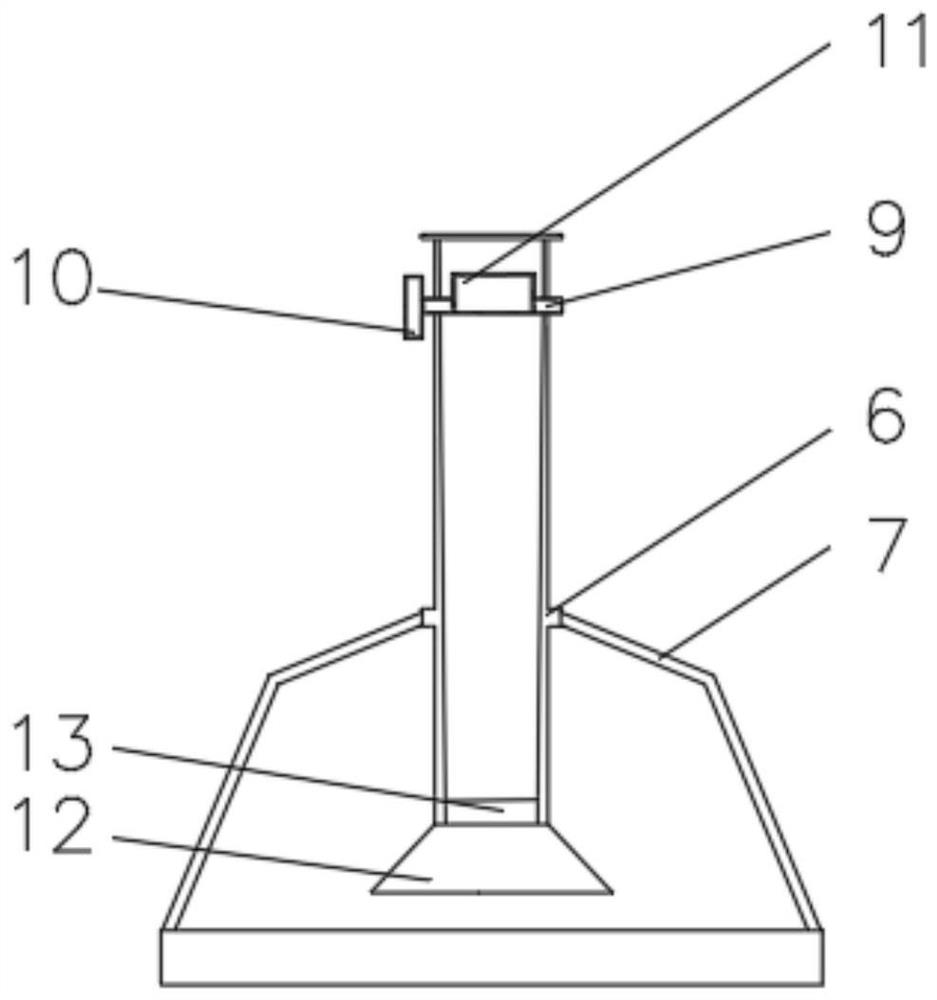

[0031] see Figure 1-3 , the present invention provides a technical solution: a feeding device, including a charging frame 1, one side of the charging frame 1 close to the top is connected with a feeding pipe 2, and one side of the charging frame 1 away from the feeding pipe 2 The bottom plate 3 is installed on the side, and the side of the charging frame 1 close to the bottom plate 3 is connected with the discharge pipe 4. The position of the discharge pipe 4 close to the bottom plate 3 is provided with a reinforcement ring 5, and the outer side of the discharge pipe 4 is provided with a fixed ring. 6. A bracket 7 is evenly installed on the side of the fixed ring 6 away from the discharge pipe 4, and the end of the bracket 7 away from the fixed ring 6 is fixedly connected with the feeding frame 8, and the side of the discharge pipe 4 is installed near the reinforcement ring 5. Rotating rod 9, one end of rotating rod 9 runs through the discharge pipe 4 and is fixedly connected...

Embodiment 2

[0038] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, an arc-shaped baffle 17 is installed on the inner wall of the discharge pipe 4 close to the position of the rotating rod 9, and a scraper 18 is evenly installed on the inner side of the arc-shaped baffle 17 .

[0039] A rotating ring 19 is sleeved on one side of the rotating rod 9 close to the scraper blade 18 , and a fixing plate 20 is installed on one side of the rotating ring 19 .

[0040] A crushing device 11 is installed on one side of the rotating rod 9, and the crushing device 11 includes an outer frame 111, and one side of the outer frame 111 is provided with a groove 112, and the inner wall of the groove 112 is slidably connected with an extension plate 113 by a sliding rod 115, Blades 114 are evenly installed on one side of the extension plate 113 close to the groove 112 , and a discharge hole 116 is opened at the bottom of the outer frame 111 .

[0041] Duri...

Embodiment 3

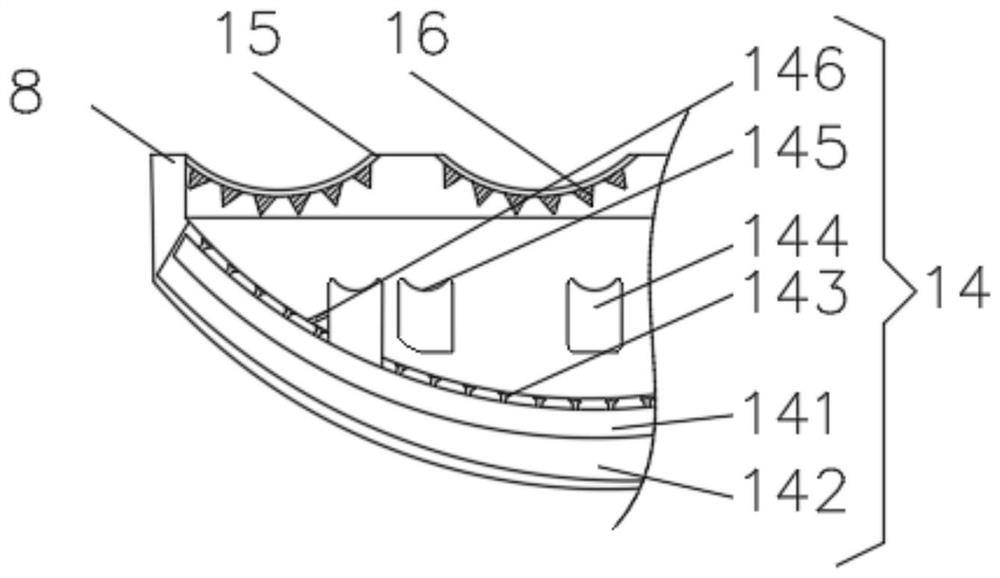

[0044] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 2, a stripping device 13 is installed on the inner wall of the discharge pipe 4 close to the baffle plate 12, and the stripping device 13 includes a first touch lever 131, the first One end of the touch lever 131 is rotatably connected to the discharge pipe 4, and a second touch lever 132 is installed on the inner wall of the discharge pipe 4 near the first touch lever 131, and the second touch lever 132 is close to the first touch lever. One side of 131 is equipped with a spring 133, and the end of the spring 133 away from the second touch bar 132 is fixedly connected with an elastic plate 134, and the side of the second touch bar 132 away from the spring 133 is equipped with an elastic bar 135, which is far away from the first One end of the two touch rods 132 is fixedly connected with the discharge pipe 4 .

[0045] When in use, when the feed falls into the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com