Multi-stage transmission shaft device and system

A technology of transmission shaft and transmission bearing, applied in the field of shaft transmission, can solve the problems of high cost, difficult realization, complex structure of multi-station winding structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

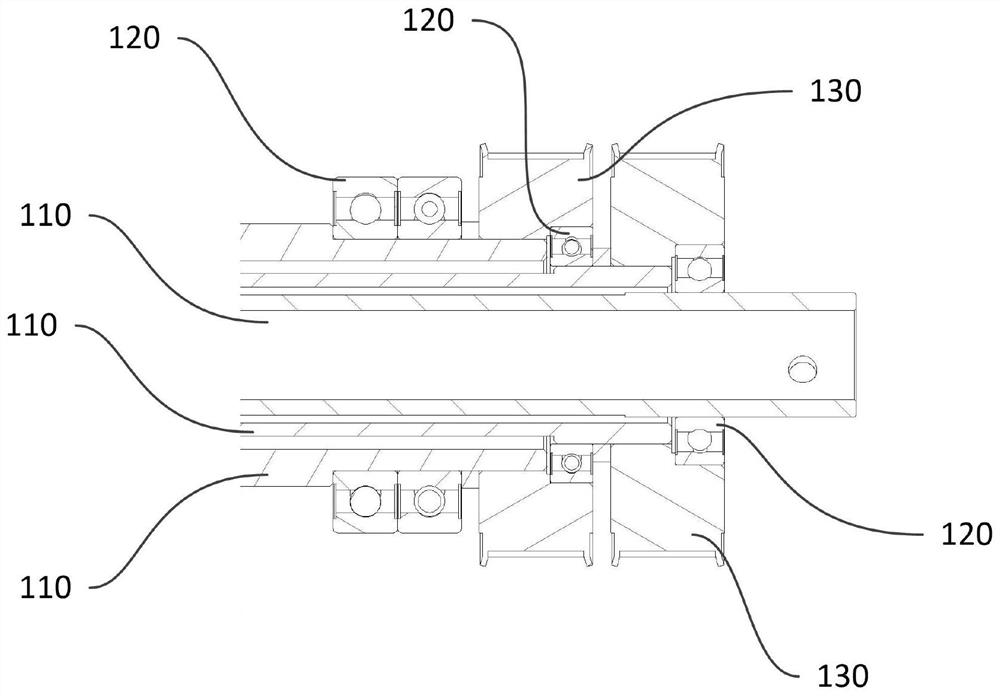

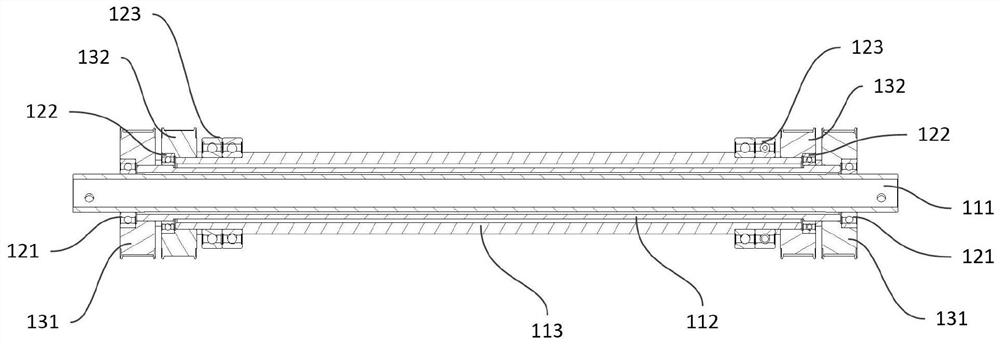

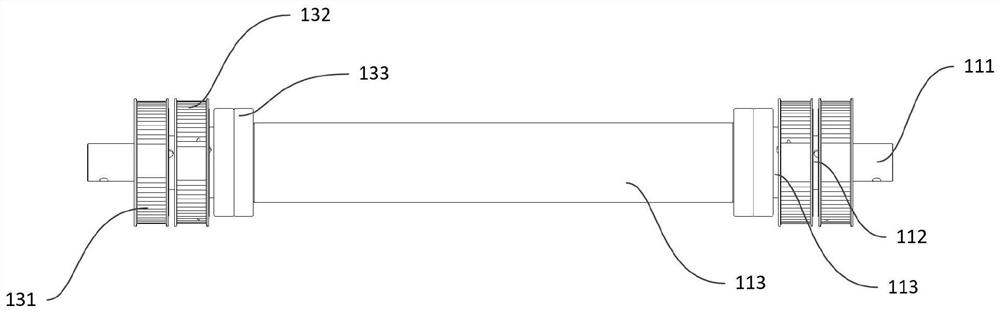

[0029] Such as Figure 1 to Figure 4 As shown, the present invention provides a preferred embodiment of a multi-stage drive shaft arrangement.

[0030] A multi-stage transmission shaft device, including a transmission shaft 110, a bearing 120 and a synchronous wheel 130, forming a multi-stage transmission structure. There are multiple transmission shafts 110, which are all coaxially stacked and sleeved. The two ends of each transmission shaft 110 Bearings 120 are provided on the sides, and the inner side of the bearing 120 is fixedly connected with the outer side of the corresponding transmission shaft 110, and the inner side of the synchronous wheel 130 is respectively connected to the outer side and adjacent side of the transmission bearing at one end of the adjacent inner transmission shaft 110. The outer side of the outer transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com