Injection machine IO module and injection machine

A technology of injection molding machine and control module, applied in the field of IO module of injection molding machine and injection molding machine, can solve the problems of low universality of safety relays, high cost of safety relays, complicated wiring, etc., to achieve simple and clear troubleshooting problems and avoid wiring confusion , the effect of enhanced versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

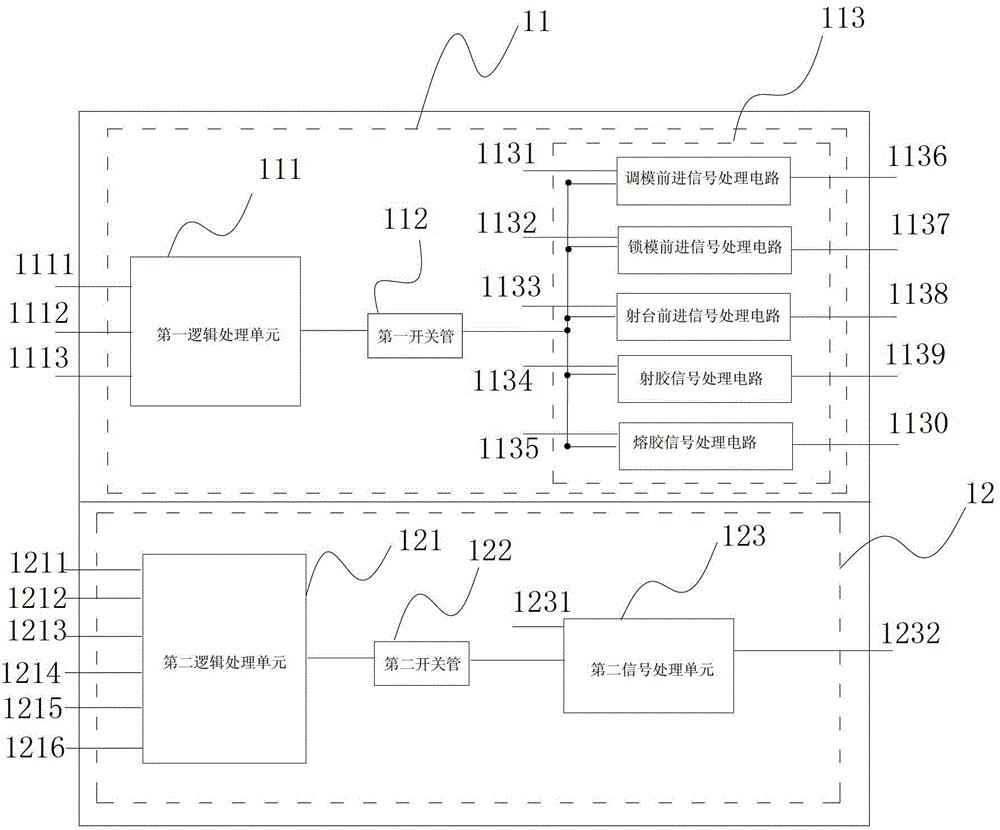

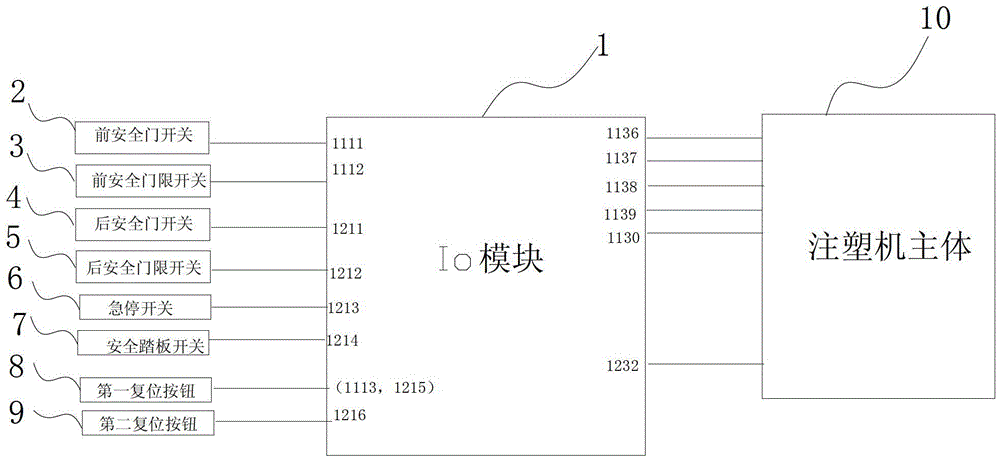

[0022] See figure 1 , An injection molding machine IO module 1, comprising: a first security level control module 11 and a second security level control module 12.

[0023] The first security level control module 11 includes: a first logic processing unit 111, a first switch tube 112, and a first signal processing unit 113.

[0024] See figure 1 with figure 2 , The input terminals (1111, 1112, 1113) of the first logic processing unit 111 are respectively connected to the front safety door switch 2, the front safety threshold switch 3 and the first reset button 8 of the injection molding machine, and the control terminal of the first switch tube 112 is connected to the first The output terminal of the logic processing unit 111, the input terminal of the first signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com