Small motor closed-slot cast-aluminum rotor

A technology for cast aluminum rotors and small motors, which is applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of increasing the cost of maintenance and use of cast aluminum rotors, the inability to disassemble and assemble, and the inability to replace parts and components. Facilitate popularization and avoid high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

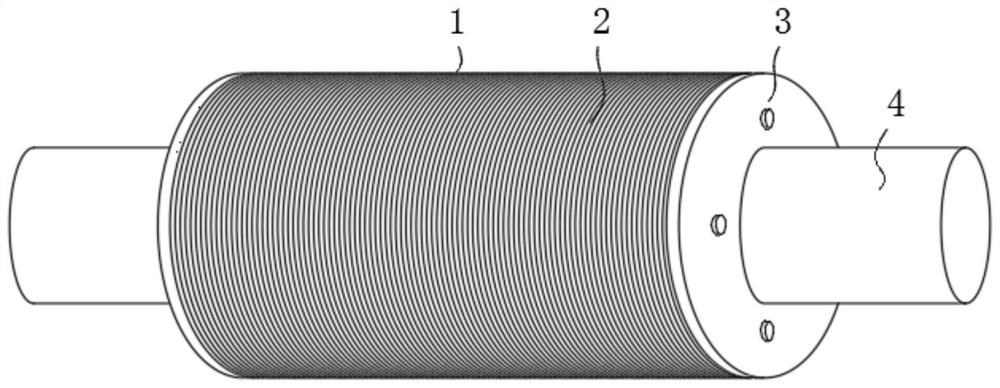

[0036] Such as Figure 1-Figure 3 As shown, a closed-slot cast aluminum rotor of a small motor includes a rotor core 1:

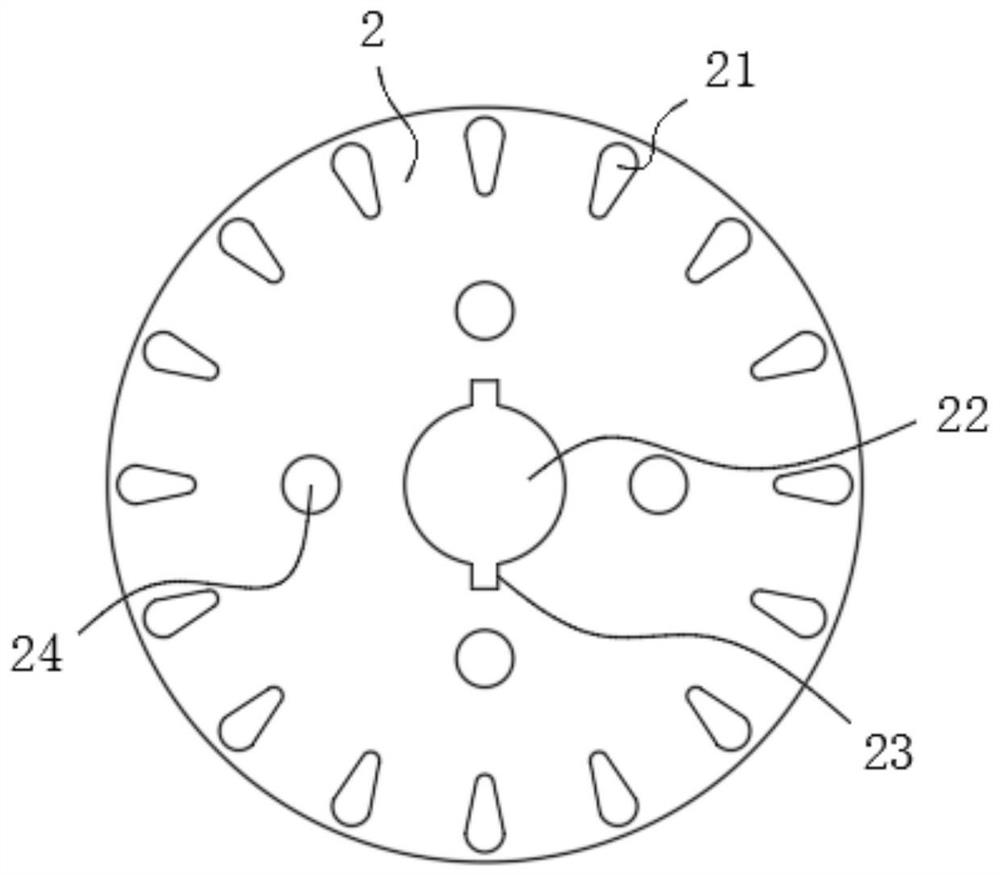

[0037] The rotor core 1 is formed by stacking several rotor punches 2, and the rotor punches 2 are made of circular silicon steel sheets, which are laminated one by one and accurately;

[0038] A shaft hole 22 is provided at the center of the rotor punching plate 2, and a rotating shaft 4 is provided through the shaft hole 22 along its axial direction;

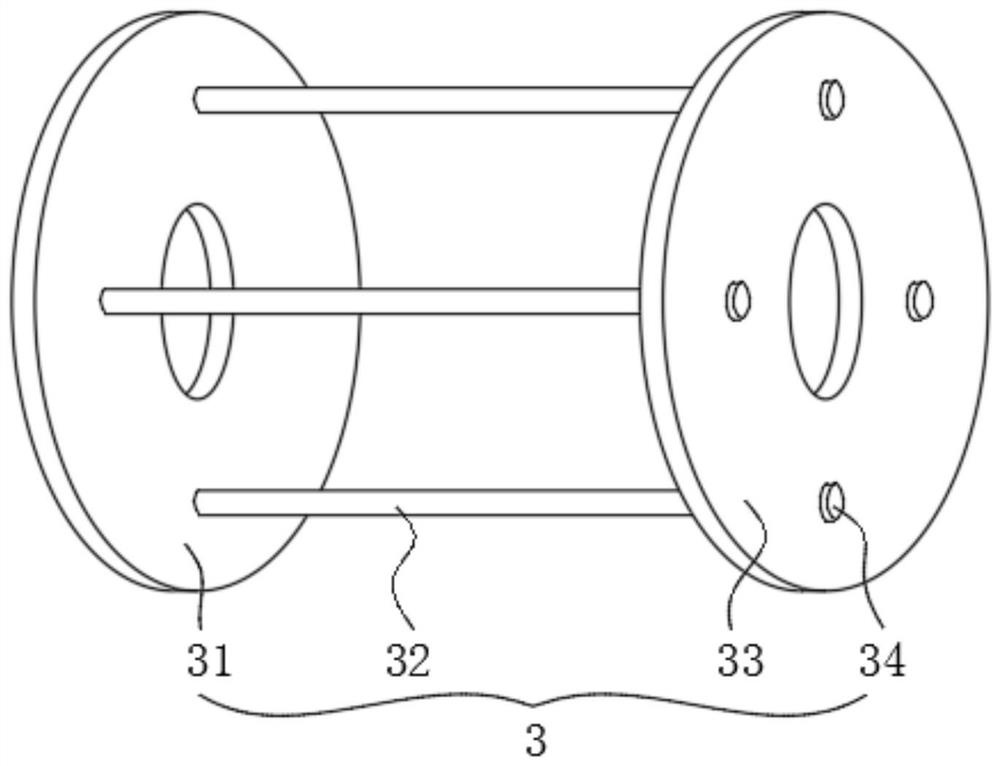

[0039] It also includes a squirrel cage 3. The squirrel cage 3 includes several cast aluminum rods 32 that pass through the upper limit hole 24 of the rotor punch 2. A rear end cover 33 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com