A kind of integrated production method of water-glue lamination and assembly of display and display

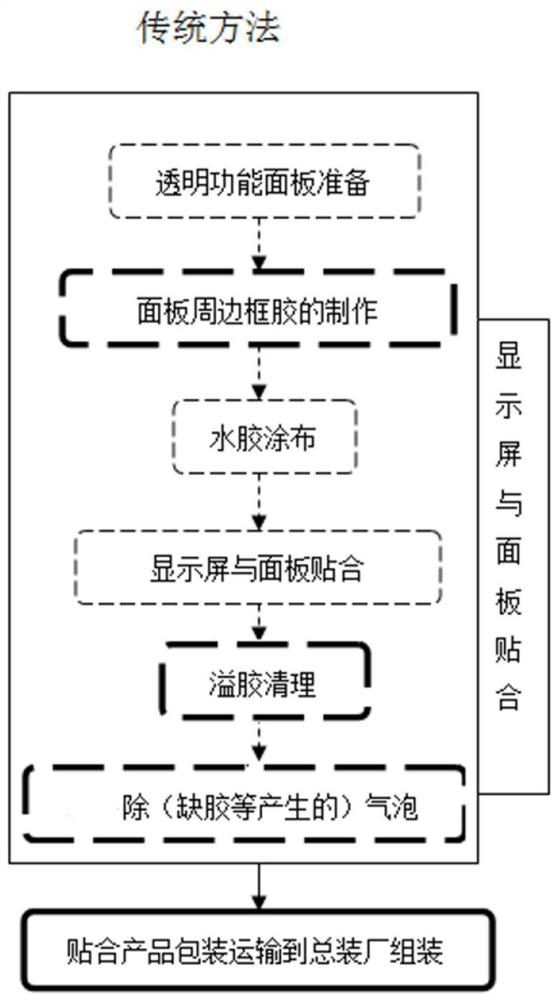

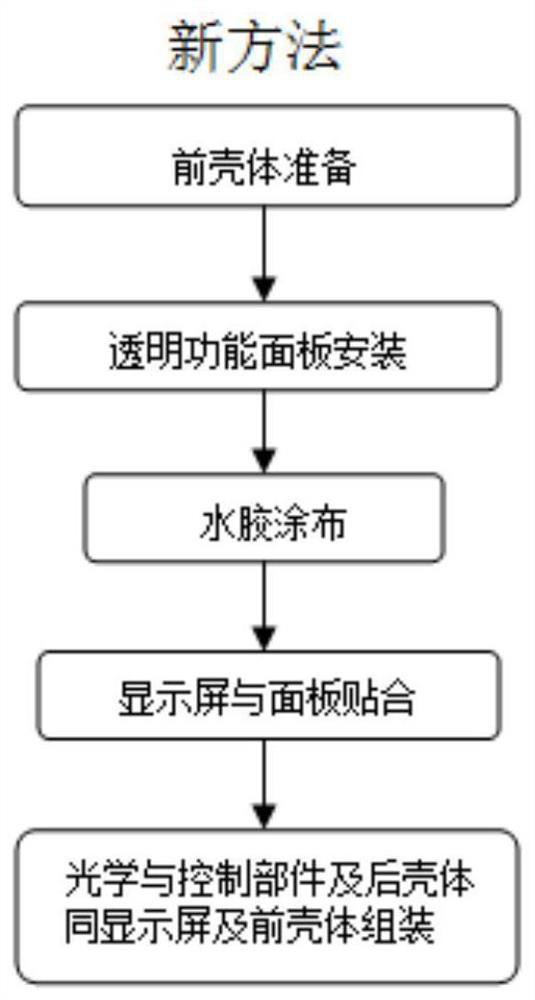

A technology of display and water glue, which is applied in the direction of instruments, identification devices, etc., can solve the problems of unavoidable cleaning of overflow glue in frame glue production, increase of production equipment and labor costs, and perfect control of glue overflow and lack of glue, so as to save glue overflow The effect of cleaning process, shortening of production cycle and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

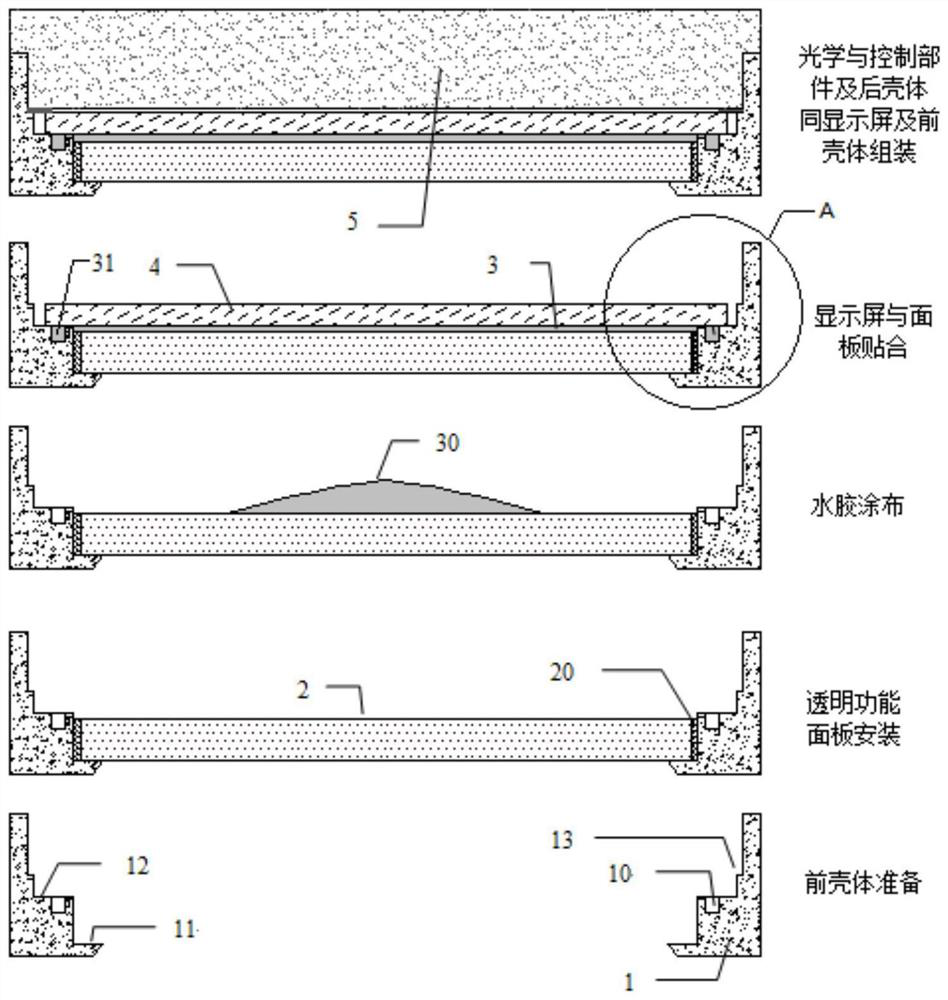

[0054] like image 3 , an integrated production method of water-glue lamination and assembly of a display, the above-mentioned display comprises: a transparent functional panel 2, a display screen 4 and a front shell 1 structure for installing and fixing the above-mentioned transparent functional panel and the display screen; The control part and the rear casing 5; the water-adhesive lamination layer 3 for laminating the transparent functional panel and the display screen, and between the inner side of the front structure of the display screen and the display screen and the transparent function panel, a groove body 100 and overflow are designed. The special water glue overflow groove 10 composed of the glue channel 101, the above-mentioned water glue lamination and assembly integrated production method, such as figure 2 shown, including:

[0055] First, turn the front shell structure 1 of the display upside down on the operating platform;

[0056] Then, face down the transp...

Embodiment 2

[0067] In the above embodiment, if the glue overflow channel 101 is on the functional isolation layer 20 between the front case and the panel, and the groove body 100 is on the front case, for example Figure 5 , constitutes the second embodiment of the present invention.

Embodiment 3

[0069] In the above embodiment, if the glue overflow channel 101 and the groove body 100 are both on the functional isolation layer 20 between the front case and the panel, such as Image 6 , constitutes the third embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com