A high-speed combined seal for a gearbox

A combined seal and gearbox technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as scrapping, lubrication medium leakage, and gearbox damage, and achieve a wide range of applications, stable performance, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

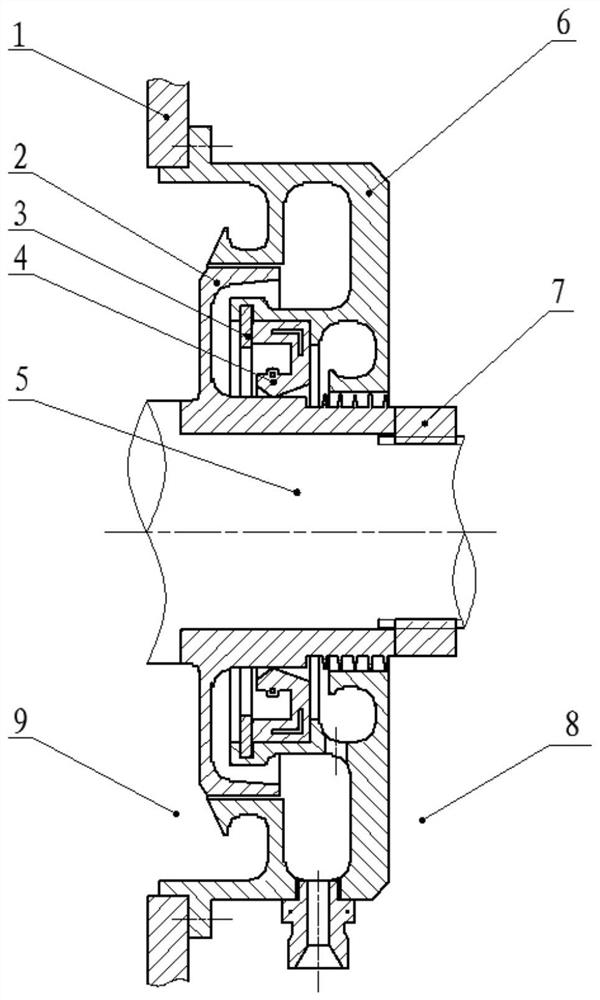

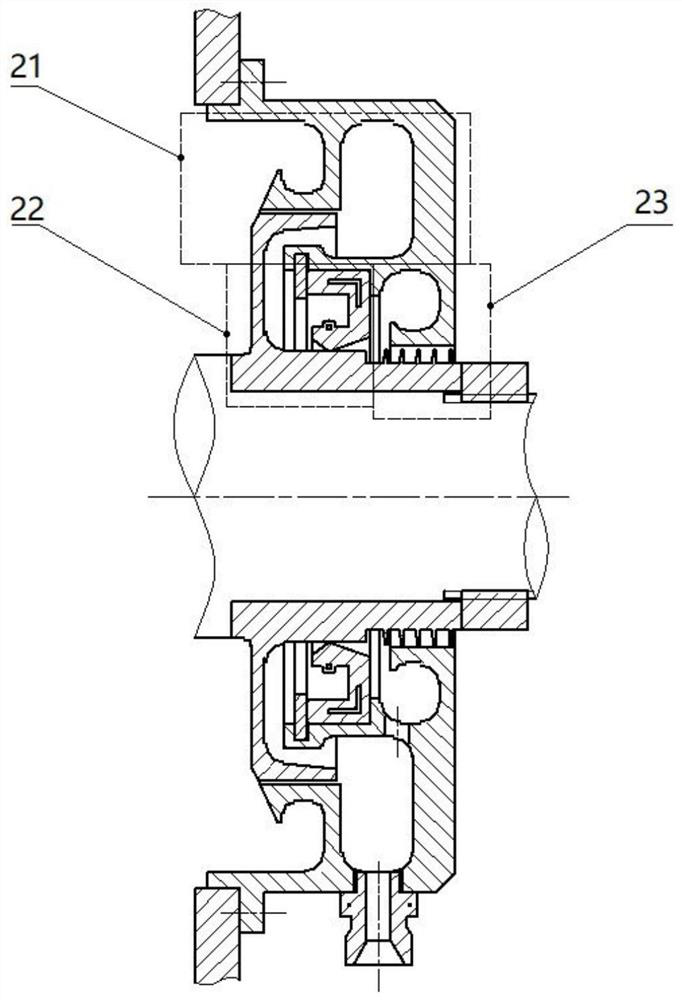

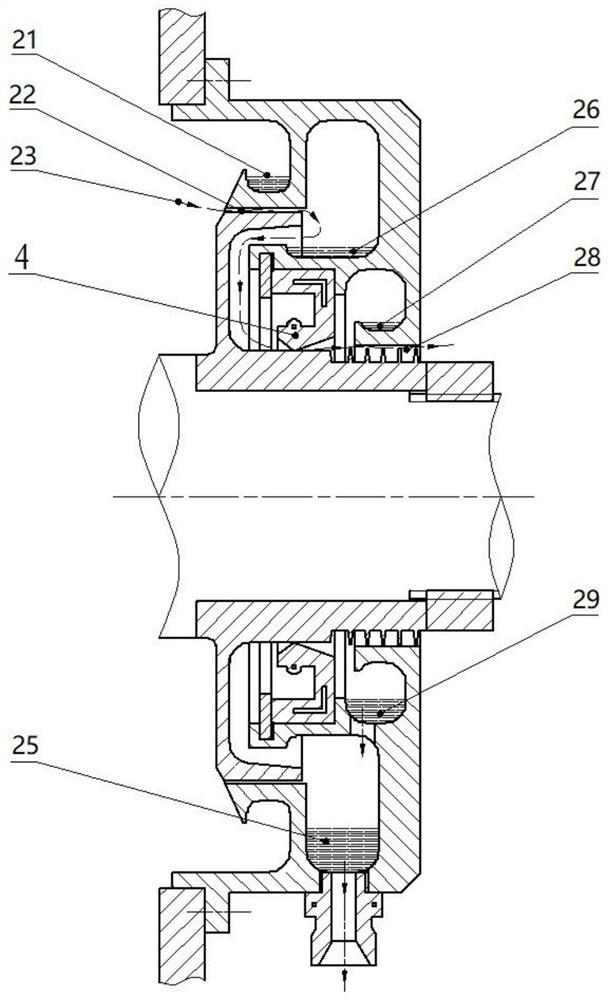

[0015] The technical scheme adopted by the present invention to solve the technical problem is: the seal adopts 13 kinds of sealing combinations of narrow gap oil collecting seal 11, lip seal 12, and oil collecting labyrinth seal. The moving ring 2 of this sealing structure is installed on the rotating shaft 5 of the gearbox, the narrow gap retaining ring 3 and the labyrinth sealing teeth are arranged on the moving ring 2, the static ring 6 of this seal is installed on the box body 1, and the static ring 6 The static ring of the narrow-gap oil-collecting seal 11 and the inner and outer two oil-collecting grooves are arranged on the top. The external oil-collecting groove can be divided into an upper groove body and a lower groove body. The third oil collection tank is set at the position, and the same oil collection tank can be divided into an upper tank body and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com