Multifunctional shale geological exploration drill bit and working method thereof

A geological exploration and multi-functional technology, applied in drilling equipment and methods, drill bits, drilling equipment and other directions, can solve the problems of torsional deformation, direct torsion, low exploration degree of drill pipe, save cost, facilitate installation and disassembly, The effect of increasing the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

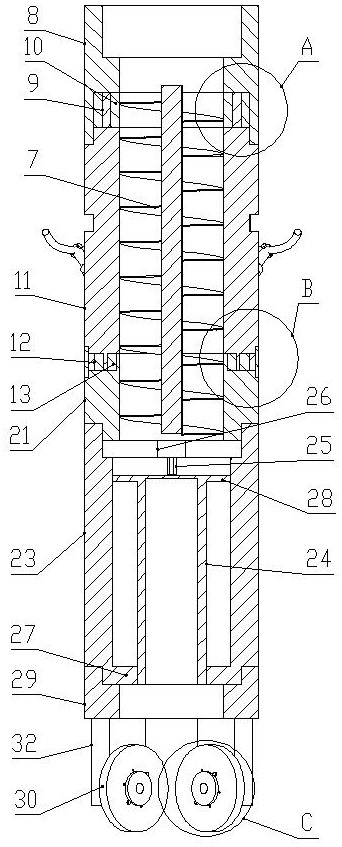

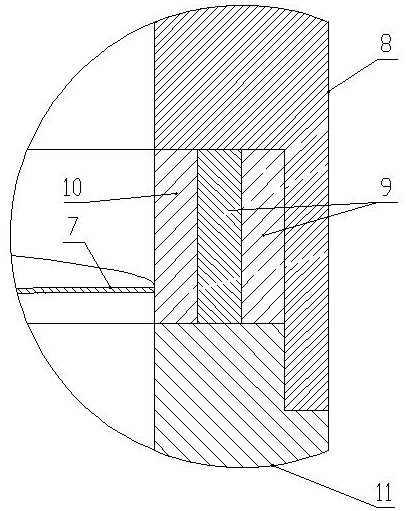

[0034] Such as Figure 1-Figure 9 As shown, a multi-functional shale geological exploration drill bit of the present invention includes a drill pipe connection system 1, an auxiliary power system 2, a transfer system 3, a sampling system 4 and a cutting system 5, which are sequentially connected coaxially from top to bottom. A locking system 6 is provided between the outer circles of the auxiliary power system 2 and the transfer system 3 , and a screw transmission impeller 7 is arranged coaxially inside the auxiliary power system 2 and the transfer system 3 .

[0035] The drill pipe connection system 1 includes a drill pipe connector 8, a first drive motor 9 and a drive sleeve 10. The upper end of the drill pipe connector 8 is coaxially connected to several sections of drill pipe until the wellhead of the exploration well. The first drive motor 9 is installed On the inner lower side of the drill pipe connector 8, the stator of the first drive motor 9 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com