A method and system for maintaining the tension of fiber yarns in groups

A technology of yarn tension and fiber, which is applied in the field of fiber yarn tension control, and can solve the problems of difficulty in controlling the consistency and stability of multi-strand yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

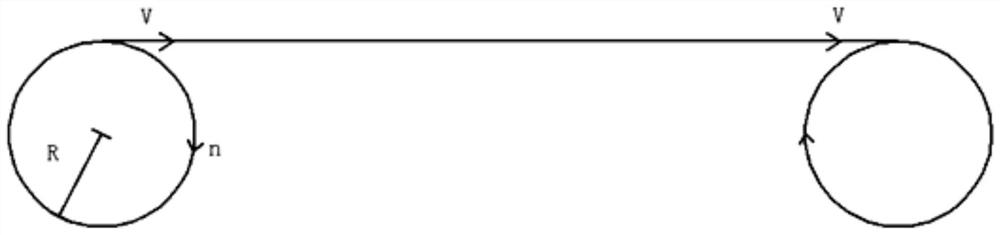

[0057] A method for maintaining the tension of fiber yarns in groups, comprising the following steps: supplying power to a group of motors through the same three-phase voltage regulator. In the present invention, a torque motor is used, and the synchronous motor of the contactor voltage regulator is used to control carbon The brush slides along the surface of the coil, and adjusts the turns ratio to output the effective value of the voltage. The output voltage waveform is a sine wave, which avoids the risk of harmonic interference; calculates the real-time roll diameter of the unwinding roller; according to the required yarn tension and Calculate the required output v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com