980MPa-grade cold-rolled dual-phase steel with yield strength exceeding 700MPa and production method thereof

A technology of yield strength and production method, which is applied in the field of iron and steel smelting, can solve the problems of low yield strength and achieve the effects of avoiding plasticity reduction, improving strong plasticity, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

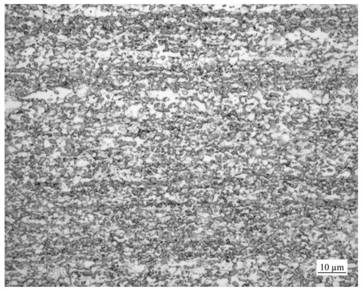

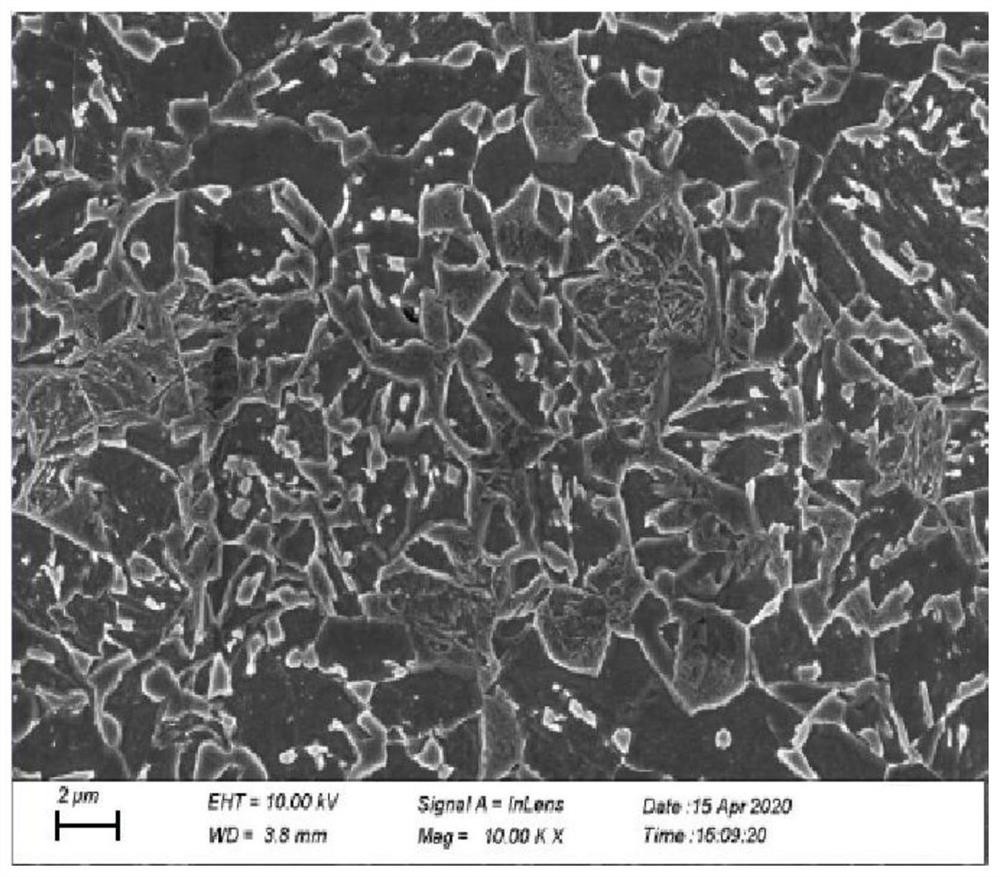

[0041] This example provides two groups of 980 MPa grade cold-rolled dual-phase steels with a yield strength exceeding 700 MPa as Example 1 and Example 2, the chemical composition of which is shown in Table 1.

[0042] Table 1 Chemical composition of cold-rolled dual-phase steel (wt.%)

[0043]

[0044]

[0045] The production method of the above-mentioned 980MPa-grade cold-rolled dual-phase steel with a yield strength exceeding 700MPa, the specific process is as follows:

[0046] a. Smelting process: through the smelting process, a dual-phase steel slab with the chemical composition shown in Table 1 is prepared, wherein the V content of the original molten iron is controlled in the converter, instead of additionally adding ferro-vanadium;

[0047] b. Hot rolling process: the slab is heated, dephosphorized, hot rolled and laminar cooled to obtain a hot rolled coil. The specific hot rolling process parameters are shown in Table 2.

[0048] Table 2 Main process parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com