High-tensile-resilience heat-resistant pressure-sensitive adhesive and preparation method thereof

A technology of resilience and heat resistance, which is applied in the field of preparation of high tensile resilience heat-resistant pressure-sensitive adhesives and high-stretch resilience heat-resistant pressure-sensitive adhesives, which can solve the deformation of pressure-sensitive adhesives and unstable performance of electronic products , poor heat resistance and other problems, to achieve the effect of good initial adhesion and holding force, high market application prospects, and good stretching resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

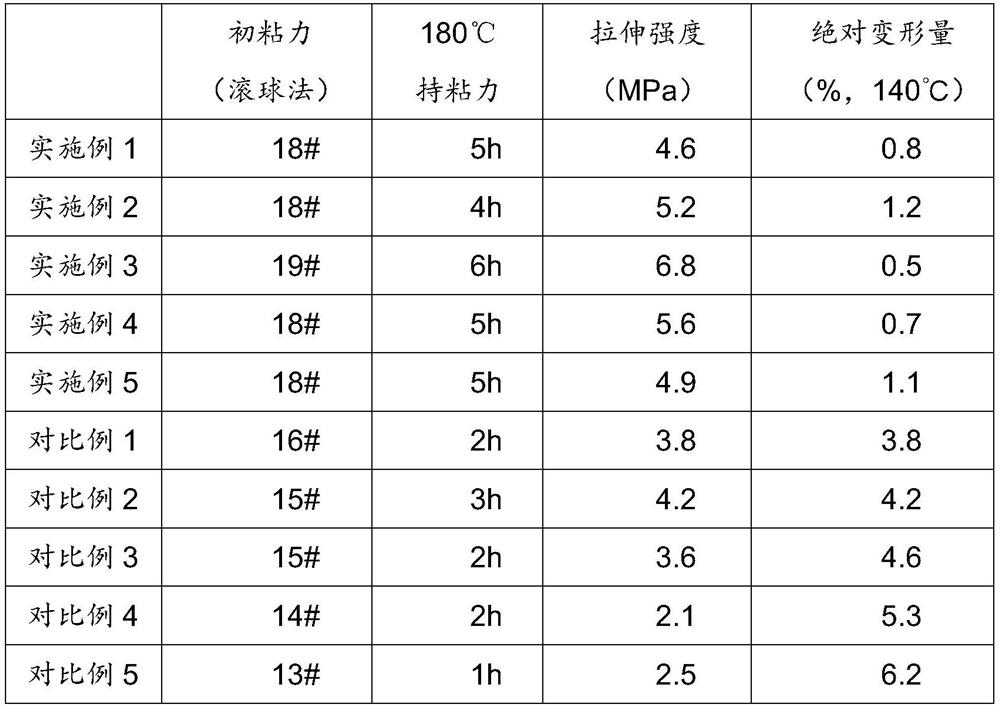

Examples

Embodiment 1

[0059] A heat-resistant pressure-sensitive adhesive with high tensile resilience, by weight components, comprising the following components:

[0060] 20 parts of alkoxyalkyl (meth)acrylate

[0061] 3 parts of 2-acrylamide-2-methylpropanesulfonic acid

[0062] 2,4-toluene diisocyanate 2 parts

[0063] 5 parts of 1,4-butanediol diacrylate

[0064] 3 parts of 2,2'-azobisisobutyronitrile

[0065] 1 part melamine formaldehyde resin

[0066] SEBS0.2 copies

[0067] Acrylonitrile 4 parts

[0068] 2 parts isooctyl acrylate

[0069] 0.8 parts of O-(7-azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium hexafluorophosphate

[0070] 0.5 parts of methyl ethyl ketone peroxide

[0071] 30 parts of ethyl acetate.

[0072] The preparation method of the above-mentioned high tensile resilience heat-resistant pressure-sensitive adhesive comprises the following steps:

[0073] (1) Add alkoxyalkyl (meth)acrylate, 2,4-toluene diisocyanate, 1,4-butanediol diacrylate, isooctyl acrylate, ethyl...

Embodiment 2

[0077] A heat-resistant pressure-sensitive adhesive with high tensile resilience, by weight components, comprising the following components:

[0078] 25 parts of alkoxyalkyl (meth)acrylate

[0079] 5 parts of 2-acrylamide-2-methylpropanesulfonic acid

[0080] 3 parts of 2,4-toluene diisocyanate

[0081] 7 parts of 1,4-butanediol diacrylate

[0082] 4 parts of 2,2'-azobisisobutyronitrile

[0083] 2 parts melamine formaldehyde resin

[0084] SEBS0.5 parts

[0085] Acrylonitrile 5 parts

[0086] 3 parts isooctyl acrylate

[0087] 0.8 parts of O-(7-azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium hexafluorophosphate

[0088] 0.6 parts of methyl ethyl ketone peroxide

[0089] 35 parts of ethyl acetate.

[0090] The preparation method of the above-mentioned high tensile resilience heat-resistant pressure-sensitive adhesive comprises the following steps:

[0091] (1) Add alkoxyalkyl (meth)acrylate, 2,4-toluene diisocyanate, 1,4-butanediol diacrylate, isooctyl acrylate, et...

Embodiment 3

[0095] A heat-resistant pressure-sensitive adhesive with high tensile resilience, by weight components, comprising the following components:

[0096] 30 parts of alkoxyalkyl (meth)acrylate

[0097] 8 parts of 2-acrylamide-2-methylpropanesulfonic acid

[0098] 4 parts of 2,4-toluene diisocyanate

[0099] 8 parts of 1,4-butanediol diacrylate

[0100] 5 parts of 2,2'-azobisisobutyronitrile

[0101] 3 parts melamine formaldehyde resin

[0102] SEBS0.6 copies

[0103] Acrylonitrile 6 parts

[0104] 4 parts isooctyl acrylate

[0105] 1 part of O-(7-azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium hexafluorophosphate

[0106] 0.8 parts of methyl ethyl ketone peroxide

[0107] 40 parts of ethyl acetate.

[0108] The preparation method of the above-mentioned high tensile resilience heat-resistant pressure-sensitive adhesive comprises the following steps:

[0109] (1) Add alkoxyalkyl (meth)acrylate, 2,4-toluene diisocyanate, 1,4-butanediol diacrylate, isooctyl acrylate, ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com