Freeze-dried reagent manufacturing process for preventing deliquescence of freeze-dried reagent balls and freeze-dried reagent

A manufacturing process and freeze-dried preparation technology, which is applied in the freeze-dried preparation manufacturing process and the field of freeze-dried preparations, can solve the problems of deliquescence and inconvenience of freeze-dried balls, and achieve the effects of easy transportation, reconstitution and prevention of deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

[0037] A manufacturing process of freeze-dried preparations to prevent deliquescence of freeze-dried preparation balls. Since paraffin wax has certain hydrophobicity and certain airtight properties, the surface of freeze-dried preparation balls is coated with paraffin wax to protect the freeze-dried preparation balls. .

[0038] In order to realize the coating of lyophilized preparation spherical paraffin, the present invention discloses two technical schemes:

[0039] Option One

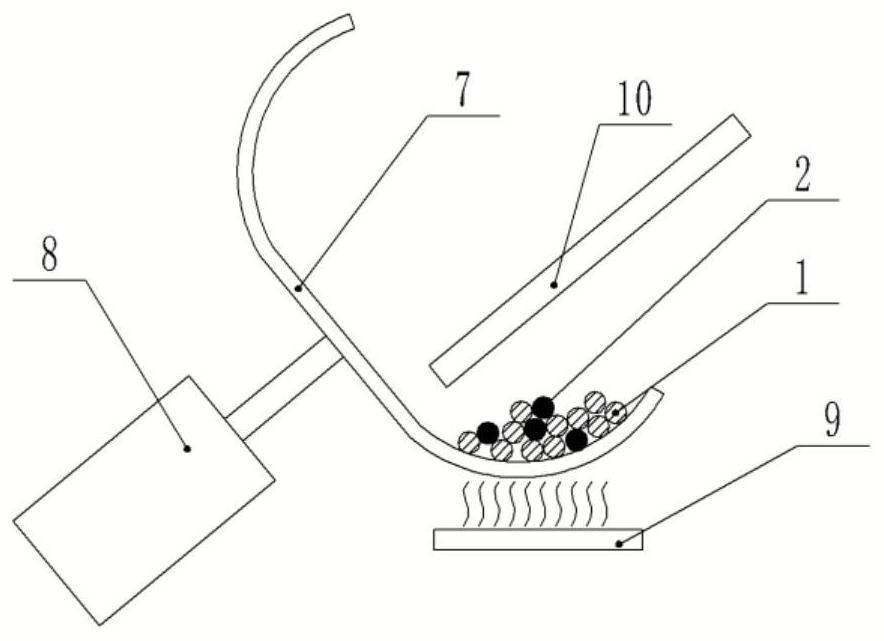

[0040] like figure 1 shown, including the following steps:

[0041] Step A, adding freeze-dried preparation balls and paraffin particles into an inclined rotating container. Put the freeze-dried preparation ball and paraffin particles into the arc-shaped rotating container, such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com