Automatic speed change electric tractor wheel edge driving device, system and method

A wheel-side drive and tractor technology, which is applied to electric devices, electric vehicles, control drives, etc., can solve problems such as the inability to meet the power requirements of electric tractors, the immaturity of products and related supporting services, and achieve light weight and compact structure. , strong anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

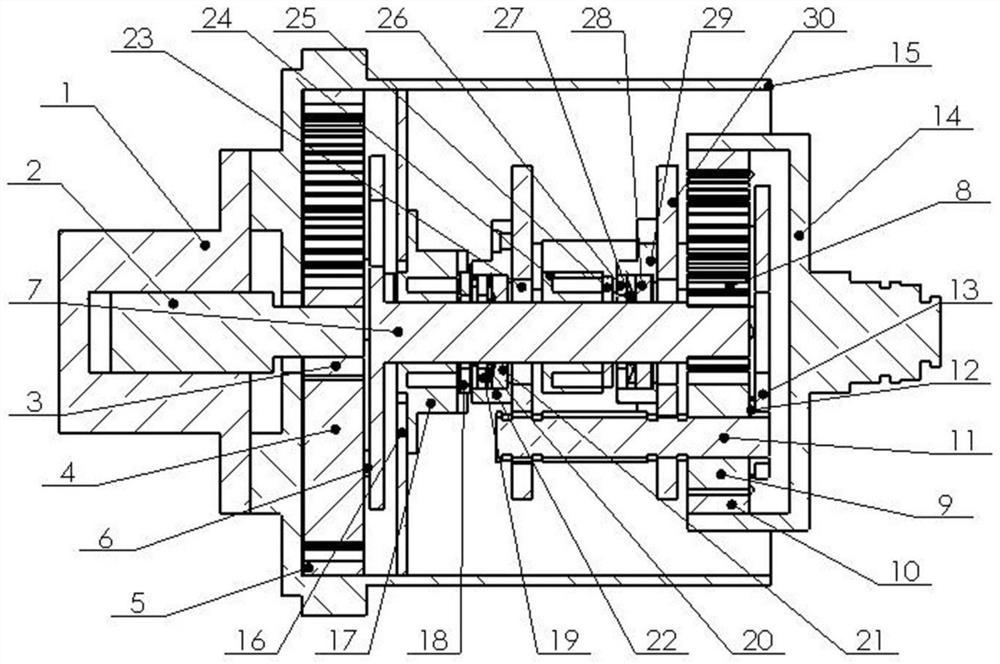

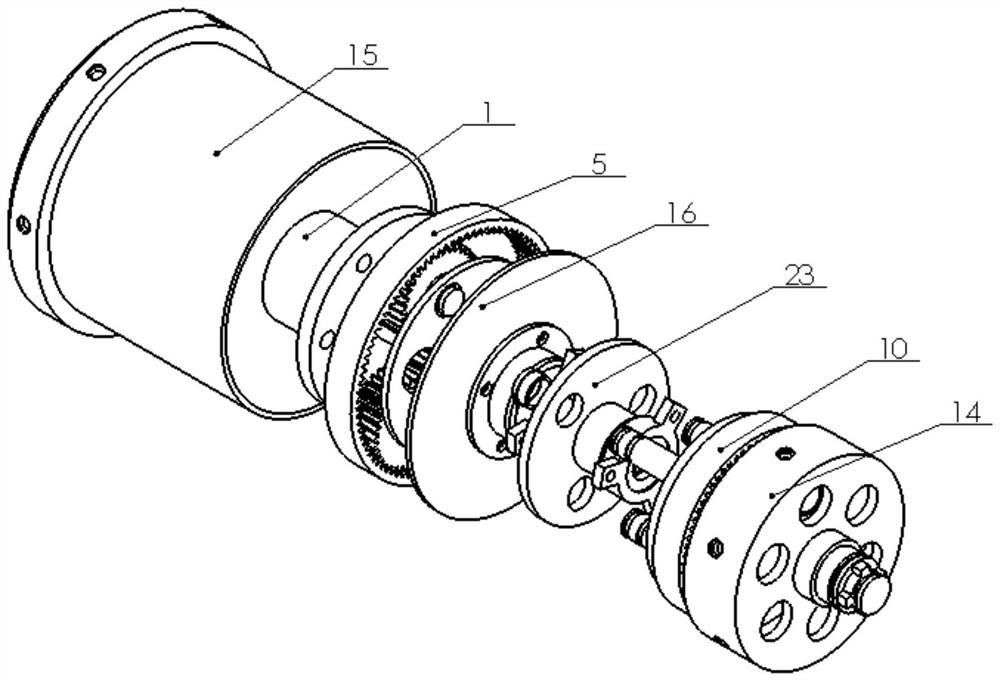

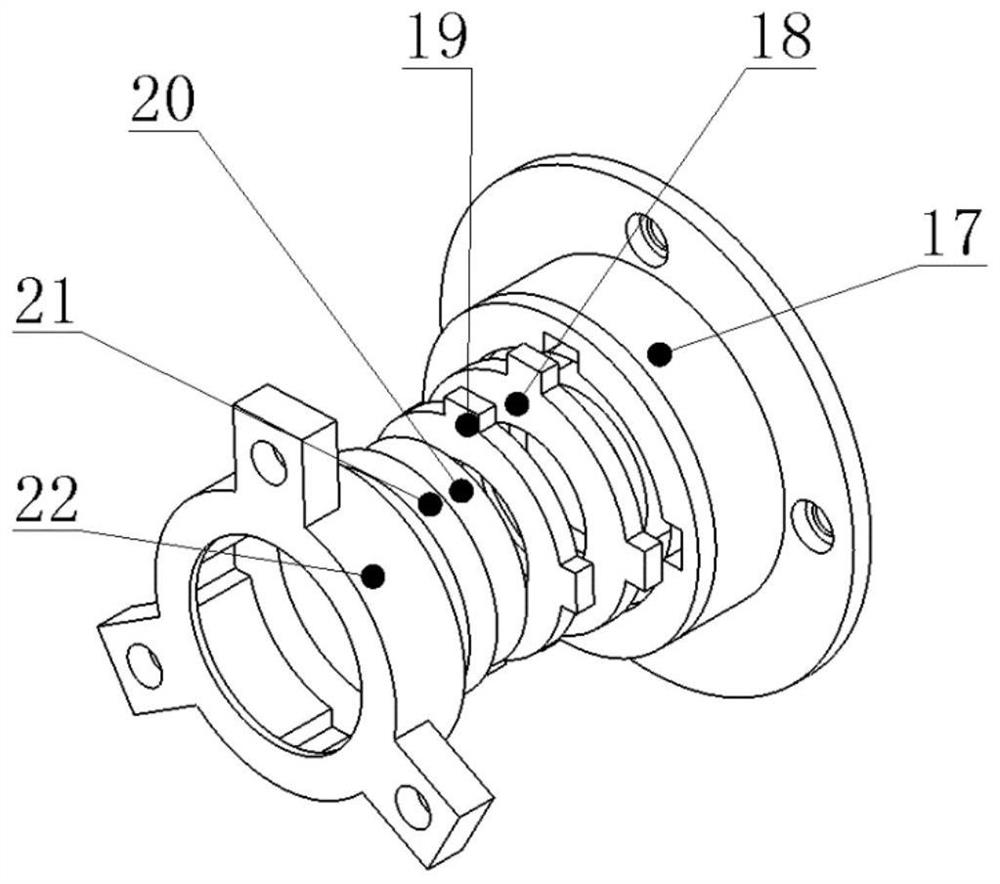

[0029] Such as figure 1 , figure 2 Shown, a kind of electric tractor wheel edge driving device, comprises high-speed stage planetary gear mechanism, low-speed stage planetary gear mechanism, first electromagnetic clutch and second electromagnetic clutch; The sun gear 3 is connected through a flat key transmission, and the first planet carrier 7 of the high-speed planetary gear mechanism is connected with the second sun gear 8 of the low-speed planetary gear mechanism through a flat key transmission connection; the second sun gear 8 is connected with a plurality of second planetary gears 9 are respectively meshed, and a plurality of second planetary gears 9 are respectively meshed with the second ring gear 10, the second ring gear 10 is drilled with screw holes, the second ring gear 10 is fixedly connected with the output hub 14 by screws, the second The number of planetary wheels 9 is determined according to specific deceleration requirements; each second planetary wheel 9 i...

Embodiment 2

[0038] Based on the electric tractor wheel drive device described in Embodiment 1, this embodiment provides an electric tractor wheel drive system, such as image 3 As shown, it includes: a road condition identification module, which is used to obtain current road condition information; a working condition selection module, which is used to judge and select matching working condition information according to the current road condition information obtained by the road condition identification module; The working condition information output by the condition selection module controls the working states of the first electromagnetic clutch and the second electromagnetic clutch in the wheel drive device of the electric tractor in the first embodiment.

[0039] Such as Figure 4 As shown, the road condition recognition module includes an independent selection module, a mobile phone positioning module and a state observer; the independent selection module is the first priority, and t...

Embodiment 3

[0059] Based on the electric tractor wheel drive device described in Embodiment 1 and the electric tractor wheel drive system described in Embodiment 2, this embodiment provides an electric tractor wheel drive method, including: acquiring current road condition information; Information judgment selects the matching working condition information; according to the working condition information, the working states of the first electromagnetic clutch and the second electromagnetic clutch in the wheel drive device of the electric tractor described in the first embodiment are controlled. The current road condition information includes: the first road condition information acquired according to the driver's input, the location information of the electric tractor during operation obtained in real time according to the positioning software, and compared with the map database, the second road condition information acquired; During the operation of the electric tractor, the longitudinal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com