Thermal diaphragm preforming method suitable for Z-shaped structure composite material

A composite material and preforming technology, which is applied in the field of thermal diaphragm preforming, can solve the problem of difficult to achieve accurate positioning and fixing measures for blanks and tooling, difficult to meet the expanded application of composite material structures, low laying efficiency and quality stability, etc. problems, to achieve the effect of controllable transfer, avoiding surface instability and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

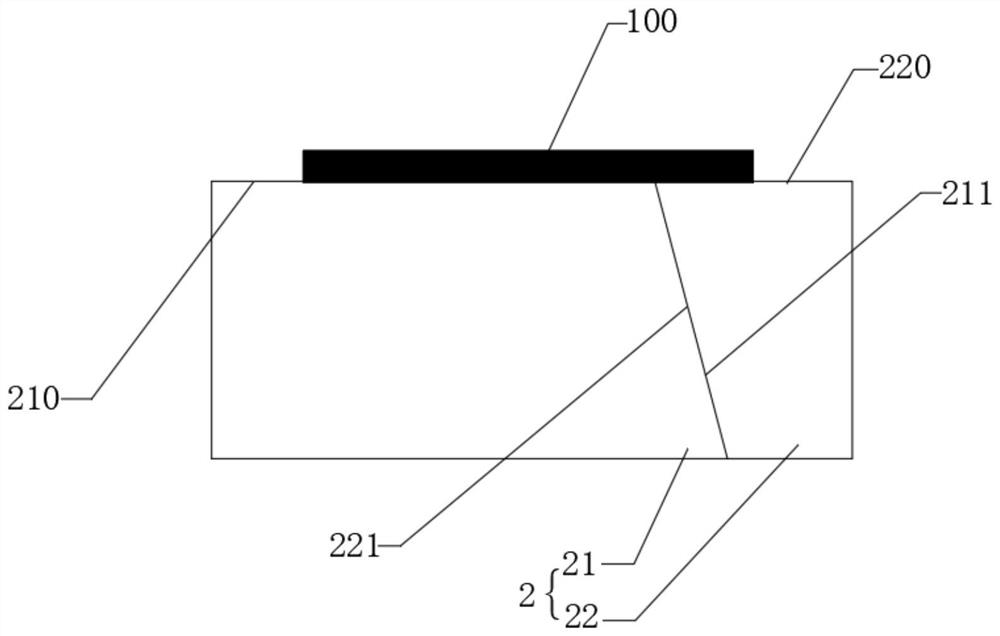

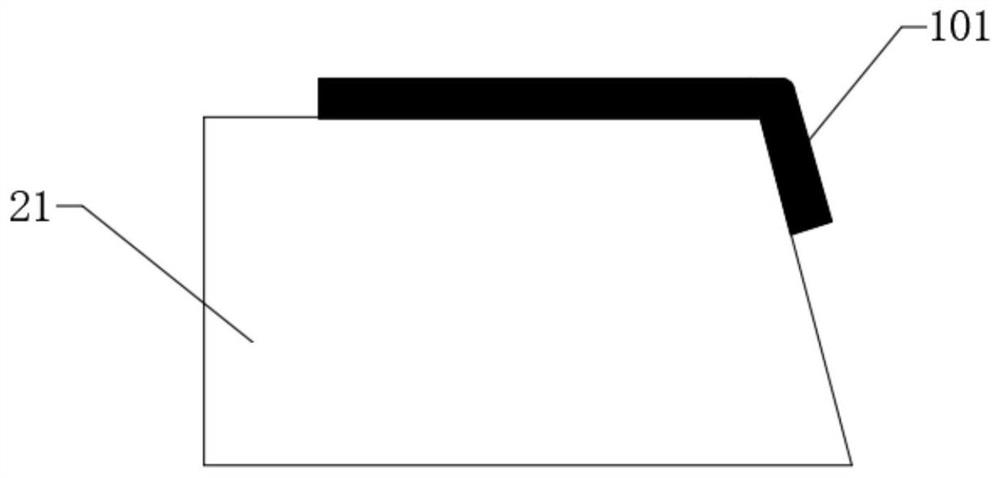

[0033] Please refer to Figure 1 to Figure 8 . The present invention proposes a thermal diaphragm preforming method suitable for Z-shaped structural composite materials. The Z-shaped structure 1 made of composite materials includes a main body 10 and edge parts bent and arranged at both ends of the main body 10 11, please refer to Figure 8 , the Z-shaped preform 1 has an inner diameter α and an outer diameter R1 on the left, and an inner diameter β and an outer diameter R2 on the right, the two inner diameters are sharp corners, and the two outer diameters are rounded corners.

[0034] The thermal diaphragm preforming method for forming the above-mentioned Z-shaped structure comprises the following steps:

[0035] Primary molding: This process is completed with the primary preforming tooling 2, the primary preforming toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com