A flexible and adjustable steam curing device for concrete components

A steam curing and concrete technology, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of inconvenient use, large volume, and limited curing space, and achieve the effects of convenient assembly and disassembly, simple device structure, and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

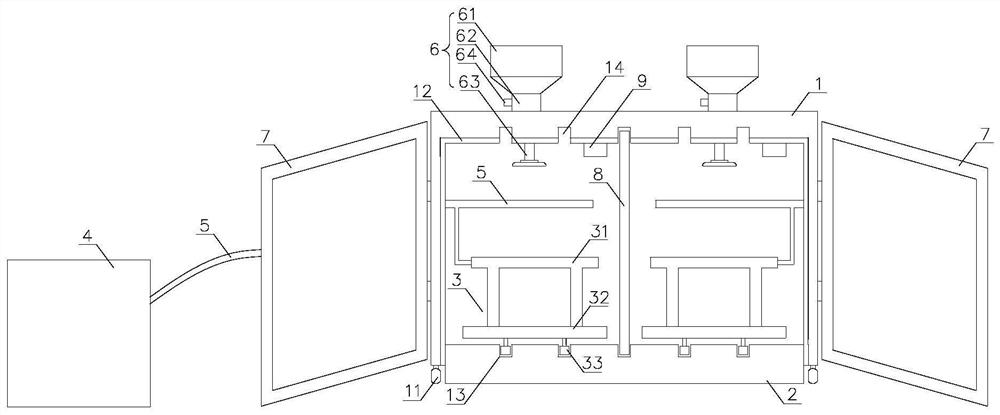

[0032] Such as Figure 1 to Figure 3 As shown, a flexibly adjustable steam curing device for concrete components includes a curing body 1 with an inverted U-shaped cross section, a base 2 adapted to the curing body 1, a plurality of support assemblies 3 for supporting concrete components, The steam equipment 4, the steam pipe 5, and the nutrient feeding mechanism 6, the temperature and humidity monitoring assembly 9 and the interactive panel 10, which are the same in number as the support assembly 3 and correspond to each other and equipped with fly ash, at least one end of the maintenance body 1 is open set, and the opening is provided with a maintenance door 7 for opening or closing the opening, the maintenance bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com