Fast bed reaction method and fast reaction bed for ultrafine particles

A technology of ultra-fine particles and rapid response, applied in chemical instruments and methods, microcapsule preparations, microsphere preparation, etc., to achieve the effect of preventing uneven reaction, ingenious and simple structure, and realizing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

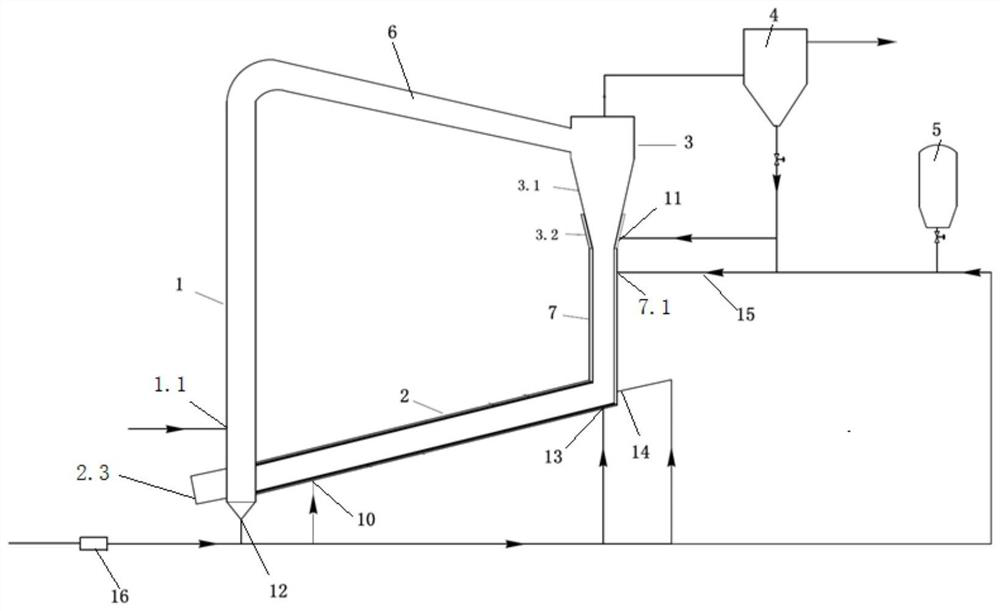

[0032] The structure of the present invention will be further explained below in conjunction with the accompanying drawings:

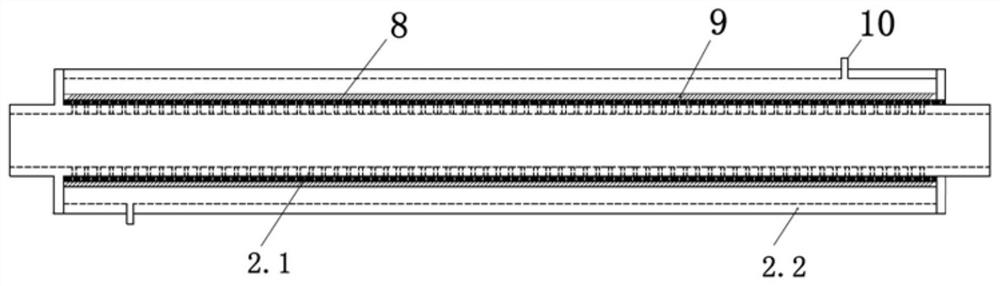

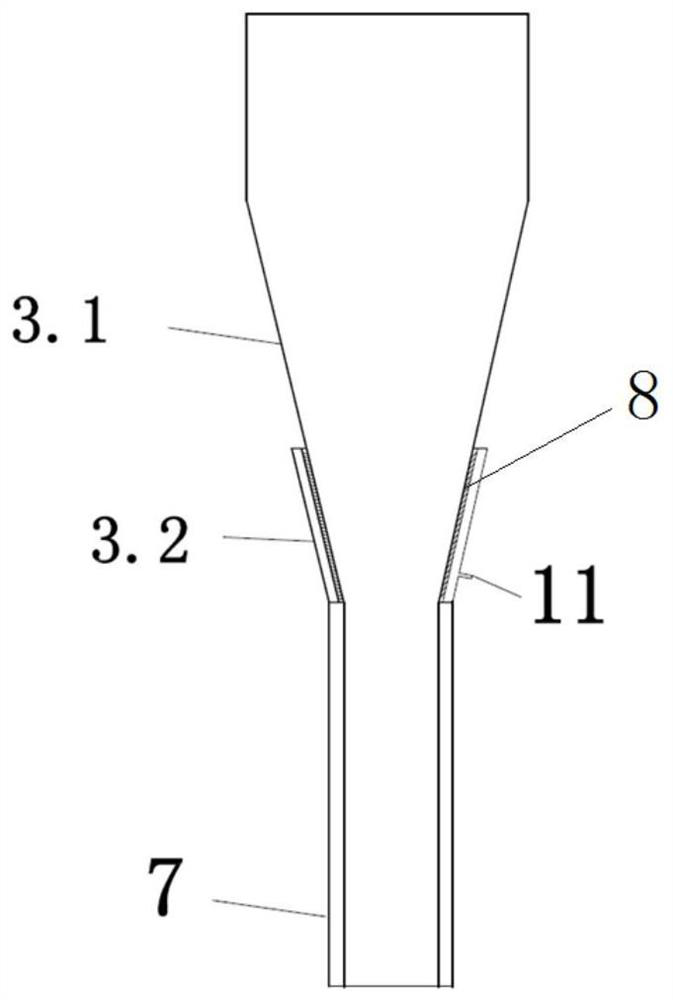

[0033] see Figure 1 to Figure 3 , the fast reaction bed of the present invention comprises a cyclone separator 3, and the bottom outlet of the cyclone separator 3 is communicated with the top inlet of the cyclone separator 3 through a descending pipe 7, a conveying pipe 2, a rising pipe 1, and a connecting pipe 6, wherein , the upper section of the descending pipe 7 is provided with a feeding port 7.1, the conveying pipe 2 is a heating pipe and a discharge port 2.3 is provided at the end, and the lower section of the rising pipe 1 is provided with an air inlet 1.1. The lower end of the riser 1 is provided with a first driving gas inlet 12 with an opening facing the direction of the centerline of the riser 1; The front end of the conveying pipe 2 is provided with a third driving gas inlet 14 whose opening faces the direction of the center line of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com