Preparation of Ethyl Lactate by Catalyzed Esterification in Fixed Bed Reactor

A fixed bed reactor, catalytic esterification technology, applied in the preparation of carboxylate, the preparation of organic compounds, organic chemistry, etc., can solve the problems of large temperature difference stress, affecting the flow of heat exchange liquid, cracks and tubes, etc. The effect of thermal expansion and cold contraction, the effect of reducing the cross flow of heat exchange liquid and reducing the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

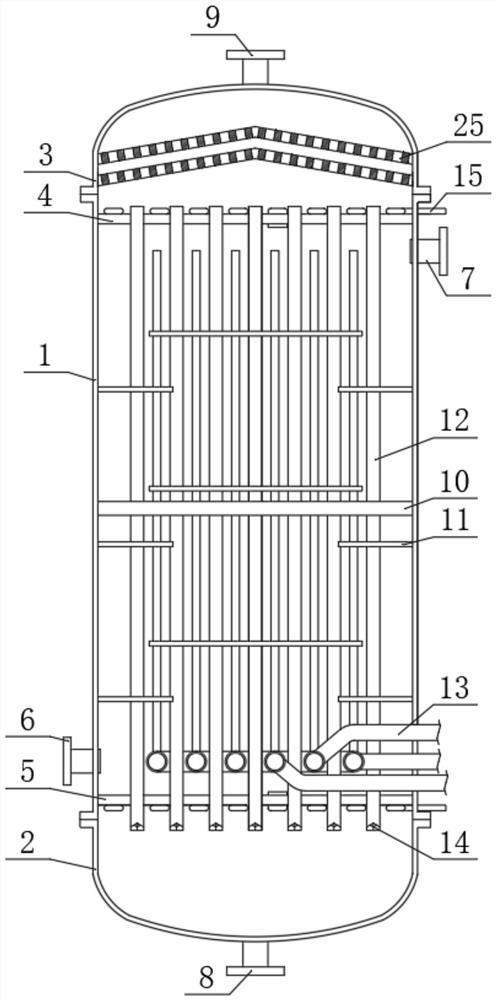

[0032] The process of catalyzing esterification by a fixed-bed reactor to prepare ethyl lactate consists of the following steps:

[0033] Step A: The material is input from the inlet port 9 of the fixed bed reactor into the fixed bed reactor;

[0034] Step B: the material entering the fixed bed reactor is input into the column tube 12 of the fixed bed reactor through the cloth plate 25 of the fixed bed reactor;

[0035] Step C: The material is reacted within the tube 12;

[0036] Step D: The material after the reaction is discharged from the column tube 12 and collected at the bottom of the fixed bed reactor, and discharged from the outlet 8 of the fixed bed reactor.

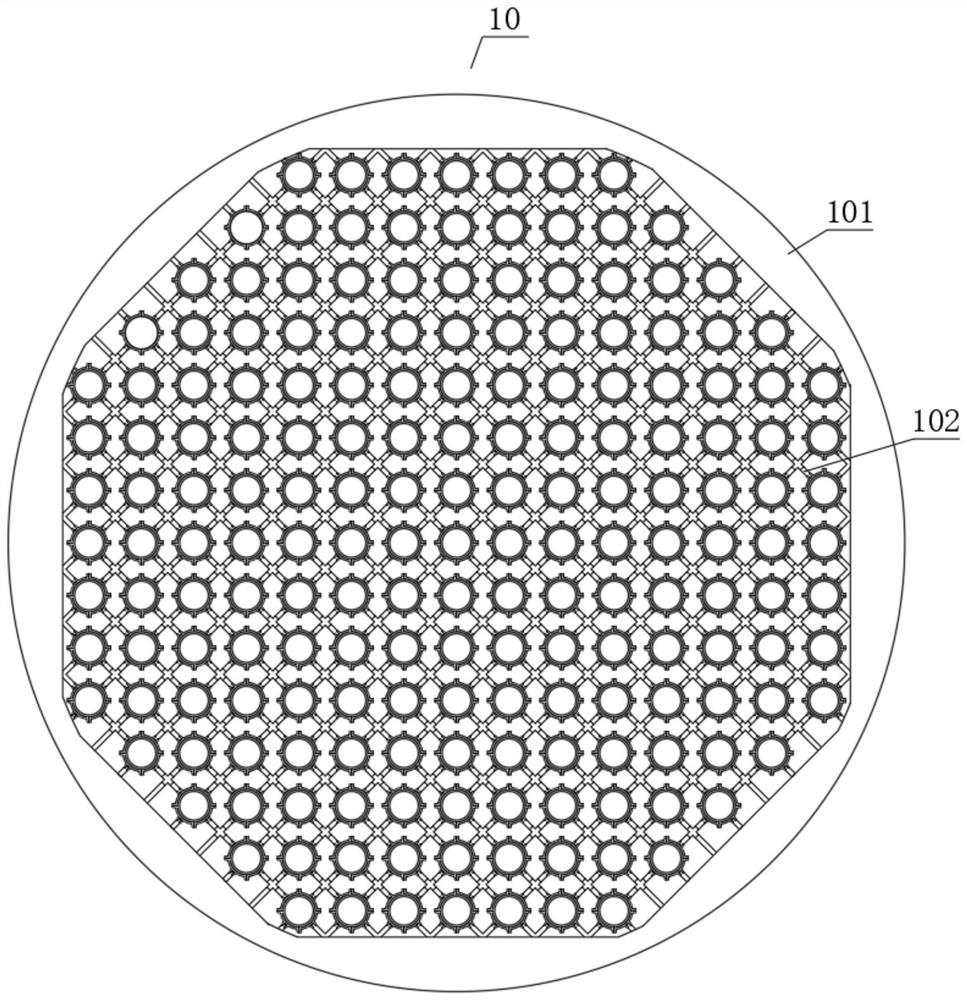

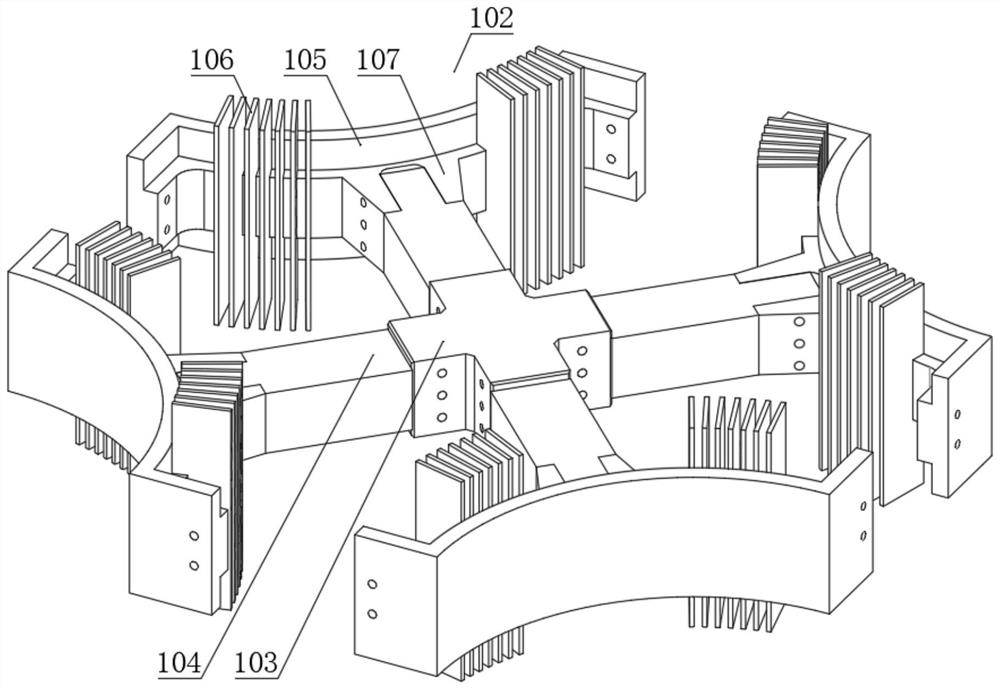

[0037] See Figure 1 , the fixed bed reactor further comprises a tank 1, respectively, disposed in the tank 1 at both ends of the upper tube plate 4 and the lower tube plate 5, respectively and the tank 1 two ends fixed connection of the upper sealing head 3 and the lower sealing head 2 and located inside the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com