Plant scented sheet for cigarette leaf group and preparation method thereof

A technology for cigarette leaves and plants, which is applied in the field of cigarette paper technology, can solve the problems such as non-prominent characteristic aroma, and achieve the effects of good coating consistency, uniform quantification, and stable fluctuation of physical indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A plant-flavored sheet for cigarette leaves, prepared from the following raw materials in parts by weight: 70-92 parts of superfine plant powder; 8-30 parts of cellulose fiber; 0.2-1 part of auxiliary agent; 1 to 5 parts of humectant; 0 to 5 parts of fragrance raw material; wherein: the superfine plant powder is characterized by: median particle size (D50) of 50.19um to 13.98um, particle size less than 20um in 25.26 %~64.05%. The auxiliary agent is an auxiliary agent comprising tamarind polysaccharide gum, modified starch and water-soluble polymer compound.

[0022] Modified starch includes: one or more combinations of oxidized starch, phosphate starch, hydroxyalkyl starch, acetate starch, and cationic starch; the water-soluble polymer compound includes: guar gum, xanthan gum, casein , one or more of polyvinyl alcohol.

[0023] Superfine plant powders are flowers represented by roses and chrysanthemums, fruits represented by plums, olives, and blueberries, diameters o...

Embodiment 2

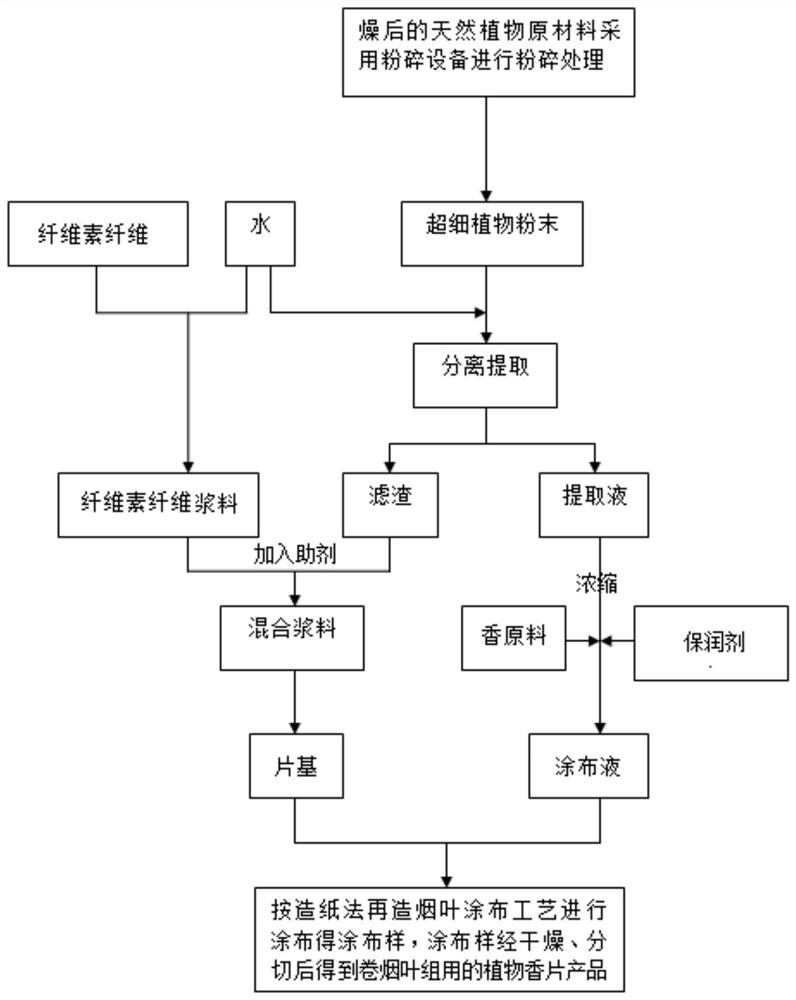

[0028] A method for preparing a plant-flavored sheet for cigarette leaves. The dried natural plant raw material is pulverized by a pulverizing device to obtain an ultrafine plant powder, which is then mixed with water for separation and extraction to obtain an extract and a filter residue; the cellulose After the fibers are mixed with water, pulping is carried out according to the pulping process. After the pulping is completed, the cellulose fiber slurry is prepared, the filter residue is mixed with the cellulose fiber slurry, and the mixed slurry is obtained after adding additives and fully mixing. The mixed slurry is prepared to obtain a film base; the extract is concentrated, and the flavor material and humectant are added to the concentrated liquid and mixed thoroughly to prepare a coating liquid, and the coating liquid and the film base are reconstituted tobacco leaves according to the papermaking method The coating process is carried out to obtain a coated sample, and th...

Embodiment 3

[0035] Embodiment 3: the herbal fragrance sheet that the cigarette leaf group is used for preparing

[0036] (1) The sun-dried and pitted plums are pulverized by crushing equipment to prepare superfine plum powder. The median diameter (D50) of the superfine tobacco powder is 26.49um, and the particle size content of less than 20um is 38.19%;

[0037] (2) Take 85 parts by weight (absolute dry mass) of the above-mentioned ultrafine plum powder and place it in an extraction tank, add 4 times the weight of water therein, extract at 70°C for 30 minutes, and filter to obtain the extract and filter residue after the extraction is completed;

[0038] (3) The extract is concentrated by a vacuum distillation concentration process to obtain a concentrated solution, and 3 parts by weight of a humectant is added to the concentrated solution to fully stir and mix evenly to prepare a coating solution for subsequent use;

[0039] (4) get the flax pulp of 15 parts by weight, carry out pulping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com