Stir-frying equipment for food processing

A technology for food processing and equipment, applied in the field of food processing stir-frying equipment, can solve the problems of low efficiency, poor stir-frying effect, increased labor intensity of staff, etc., and achieves the effect of good effect, reasonable structure and reduced labor amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

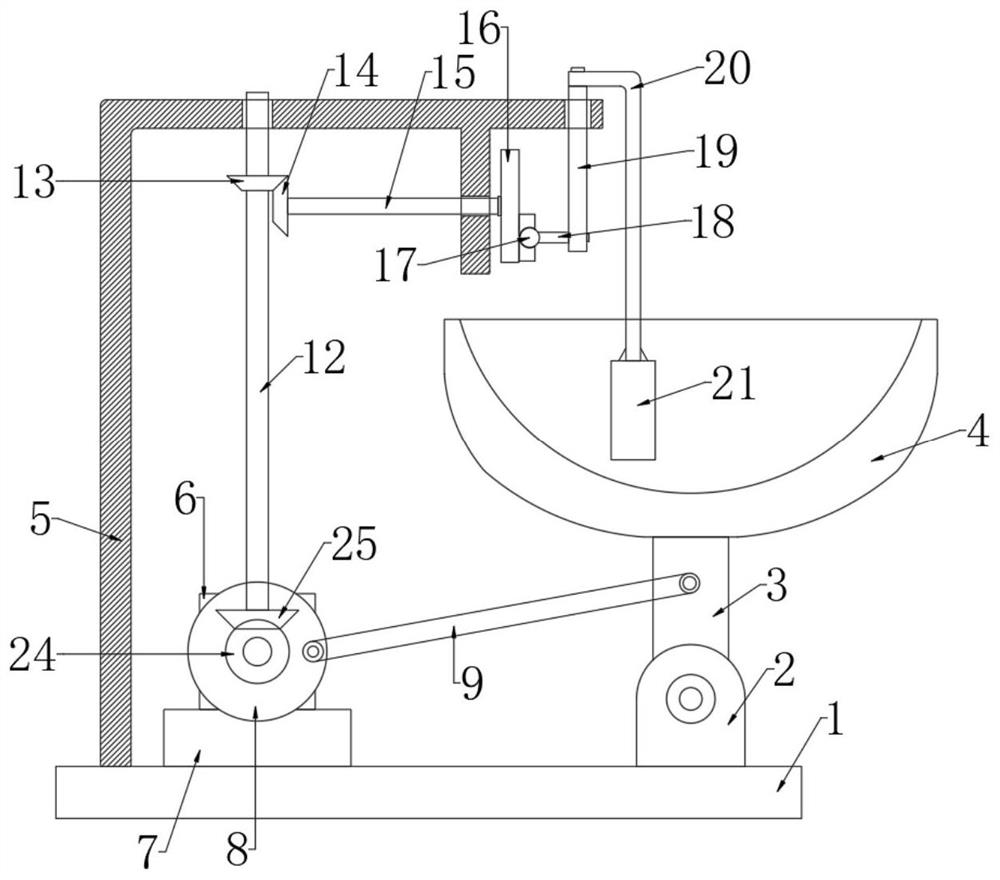

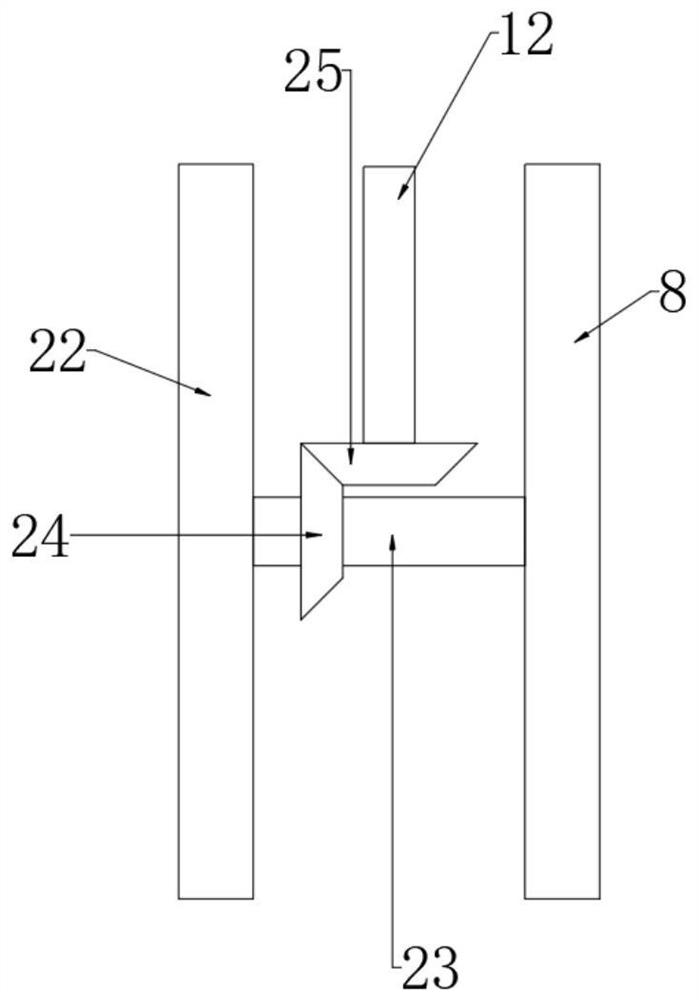

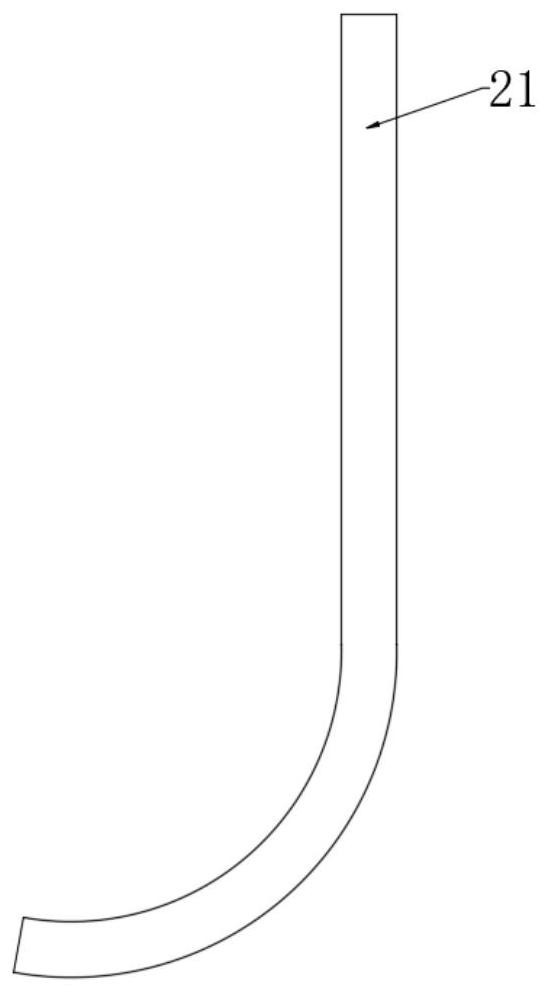

[0025] refer to Figure 1-3 , a food processing stir-fry equipment, comprising a base 1, a support base 2 is fixedly connected to the base 1, a swing rod 3 is hingedly connected to the support base 2, an electric frying pan 4 is fixedly connected to the upper end of the swing rod 3, and an electric frying pan 4 is fixedly connected to the base 1. A support plate 5 and a supporting platform 7 are fixedly connected, and a driving motor 6 and a supporting block 22 are installed on the supporting platform 7. The output end of the driving motor 6 is fixedly connected with a rotating rod 23, and the rotating rod 23 runs through the supporting block 22 and is connected to it in rotation. The first bevel gear 24 and the first circular plate 8 are successively installed on the rotating rod 23, and a pull rod 9 is hingedly connected between the first circular plate 8 and the swing rod 3, and one end of the pull rod 9 is hingedly connected with the swing rod 3. , the other end of the pul...

Embodiment 2

[0032] refer to Figure 4 The difference between this implementation and Embodiment 1 is that in this embodiment, the support plate 5 is provided with a long rod 28 connected to it in rotation up and down, a torsion spring is installed between the long rod 28 and the support plate 5, and the bottom of the long rod 28 is installed. There is a second shifting plate 10, the long rod 28 is fixedly connected with a gear lever 11, and the L-shaped bar 20 is fixedly connected with a baffle plate 26 matched with the gear lever 11; wherein the second dialing plate 10 is the same as the first dialing plate 21, The arcs of the two are oppositely arranged; the support plate 5 is provided with a through groove 27, and the L-shaped rod 20 is arranged through the through groove 27, which can ensure that the L-shaped rod 20 can swing within a certain range.

[0033]In this embodiment, when the driving motor 6 works, the L-shaped rod 20 can move upward and swing, and then the baffle 26 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com