Steak processing shape trimming device

A trimming device and shape technology, which is applied in the field of steak processing shape trimming devices, can solve the problems of low work efficiency, heavy workload, and increased steak edge loss, etc., and achieve the goals of reducing labor, low surface friction coefficient, and convenient trimming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

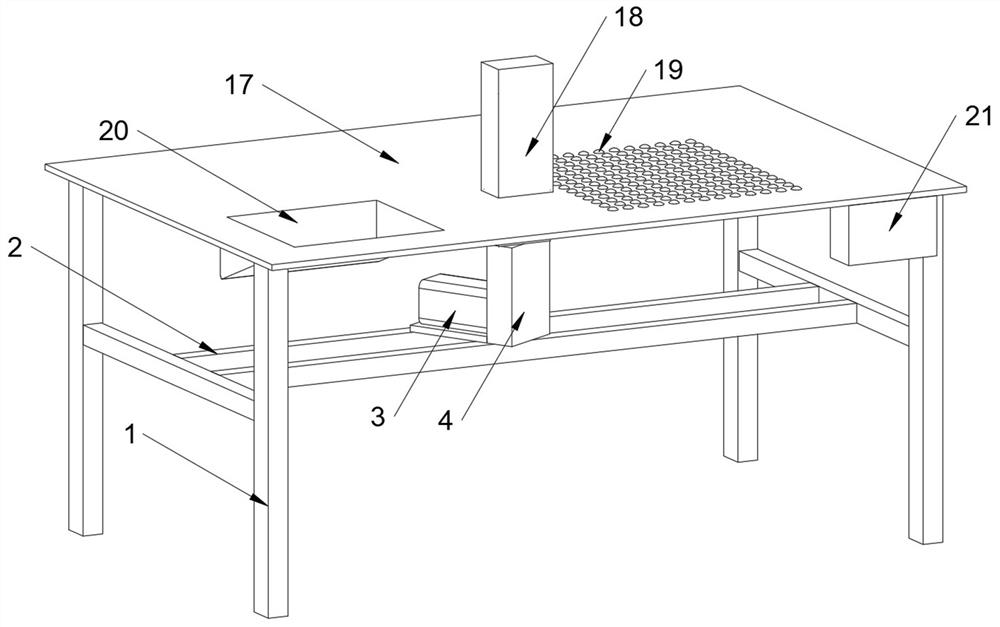

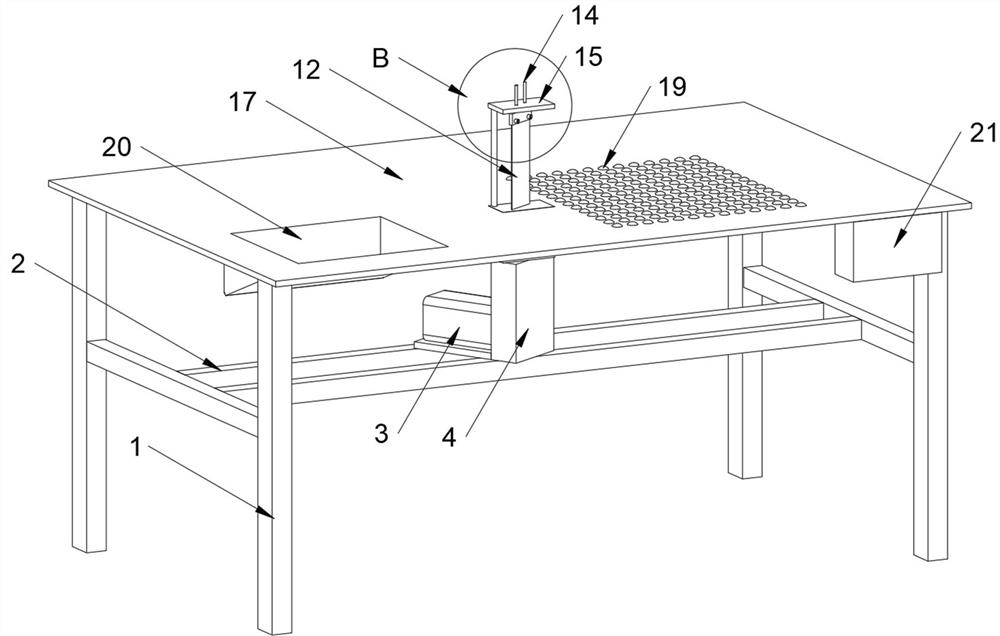

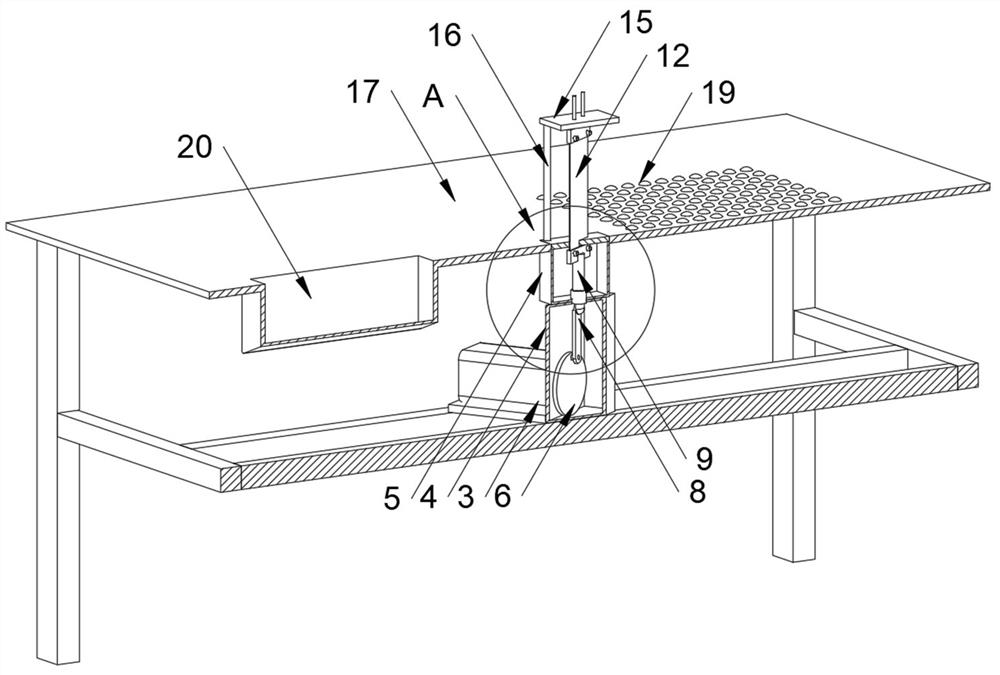

[0029] see Figure 1-Figure 9 , the present invention provides the following technical solutions: a trimming device for steak processing, including a leg 1, the legs 1 are fixedly connected to the two ends of the crossbeam 2, the top surface of the crossbeam 2 is fixedly installed with a trimming motor 3, the One side of trimming motor 3 is fixedly installed with lower casing 4, and the top surface of described lower casing 4 is fixedly installed with upper casing 5, and the output shaft of described trimming motor 3 is fixedly installed with turntable 6, and described turntable 6 passes through Rotating pin 7 rotates and connects one end of rocking bar 8, and the other end of described rocking bar 8 rotates and connects one end of slide bar 9, and described slide bar 9 slidably connects the inner wall of fixed sleeve 10, and the other end of described slide bar 9 is fixed A lower connector 11 is connected, and the lower connector 11 is fixedly connected to the bottom end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com