Garden plant maintenance equipment

A plant and equipment technology, applied in the field of maintenance equipment, can solve the problems of difficult adjustment, manual mixing of water and fertilizer mixed nutrient solution, etc., and achieve the effect of preventing random rotation and enhancing the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

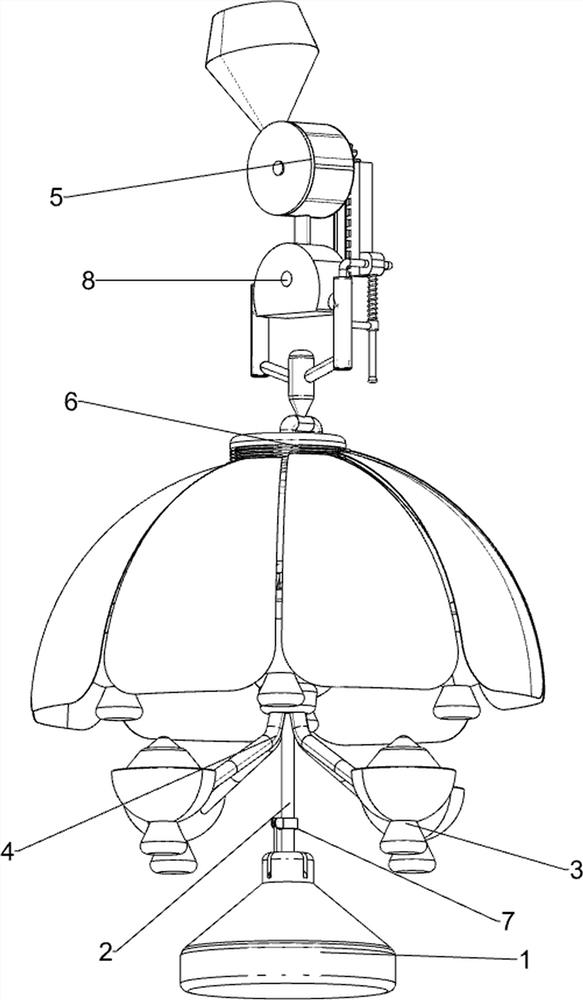

[0030] A garden plant maintenance equipment, such as figure 1 As shown, it includes a base 1, a support rod 2, a flowerpot 3, a diversion fertilization sprinkler mechanism 4 and a stirring mechanism 5, the base 1 is provided with a support rod 2 in a rotating manner, and the top of the support rod 2 is provided with a diversion fertilization sprinkler mechanism 4. Eight flower pots 3 are evenly arranged on the fertilization and watering mechanism 4 , and a stirring mechanism 5 is arranged on the top of the diverting fertilization and watering mechanism 4 .

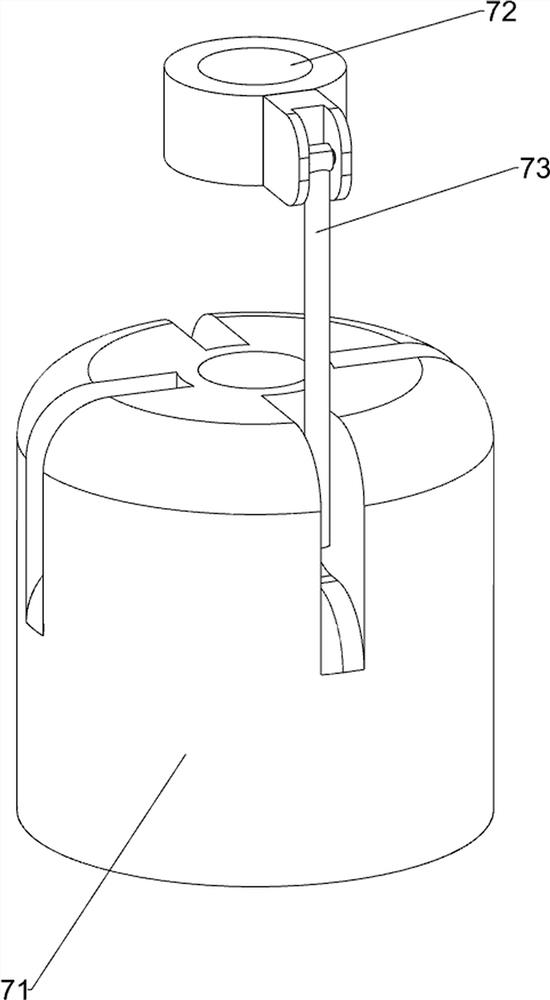

[0031] When it is necessary to uniformly fertilize and sprinkle multiple potted garden plants, this kind of maintenance equipment can be used. First, people pour the mixed nutrient solution of fertilizer and water into the stirring mechanism 5, and under the action of converting the potential energy of the liquid into kinetic energy, Stirring mechanism 5 starts to operate, so as to stir the mixed nutrient solution in it, a...

Embodiment 2

[0033] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the split fertilization and sprinkling mechanism 4 includes a first connection sprinkling frame 41, a lower water connection rod 42, a second connection sprinkling frame 43, a sprinkling connection pipe 44 and a water outlet pipe 45, and the top of the support rod 2 is provided with a first connection sprinkling frame 41 , the top of the first connection sprinkling frame 41 is provided with a water connection rod 42, the top of the water connection rod 42 is provided with a second connection sprinkling frame 43, the top of the water connection rod 42 is connected with the second connection sprinkling frame 43, and the bottom of the first connection sprinkling frame 41 Connect with the second sprinkling frame 43 bottoms and be evenly equipped with four sprinkling connecting pipes 44 around the bottom, the sprinkling connecting pipes 44 bottoms are all connected with the flowerpot 3, and the ...

Embodiment 3

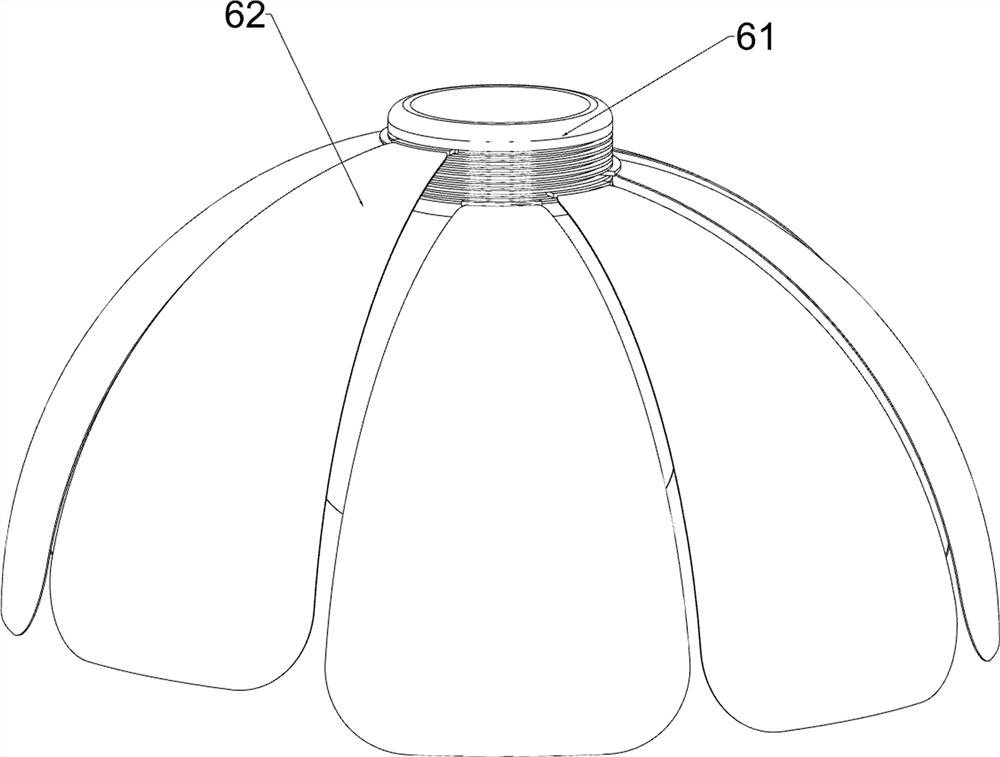

[0038] On the basis of Example 2, such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a retractable sunshade mechanism 6 is also included, and the second connection sprinkling frame 43 top is provided with a retractable sunshade mechanism 6, and the retractable sunshade mechanism 6 includes a layered connection block 61, a sunshade block 62, a sliding track 63 and a block. Block 64, the second connection sprinkling frame 43 top is provided with layered connection block 61, and the outer wall of layered connection block 61 is evenly provided with slide track 63 from top to bottom, and all sliding type is provided with stopper 64 in the slide track 63, Sunshade blocks 62 are provided on the outer sides of the block blocks 64 .

[0039] When the sun intensity is high, in order to avoid the plants from being burned, it is necessary to toggle the sunshade block 62 to make the stopper 64 slide along the sliding track 63, so that the sunshade blocks 62 are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com