Fluid mixing unit and fluid mixing method

A technology of fluid mixing and fluid, applied in the direction of mixing methods, fluid mixers, mixers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

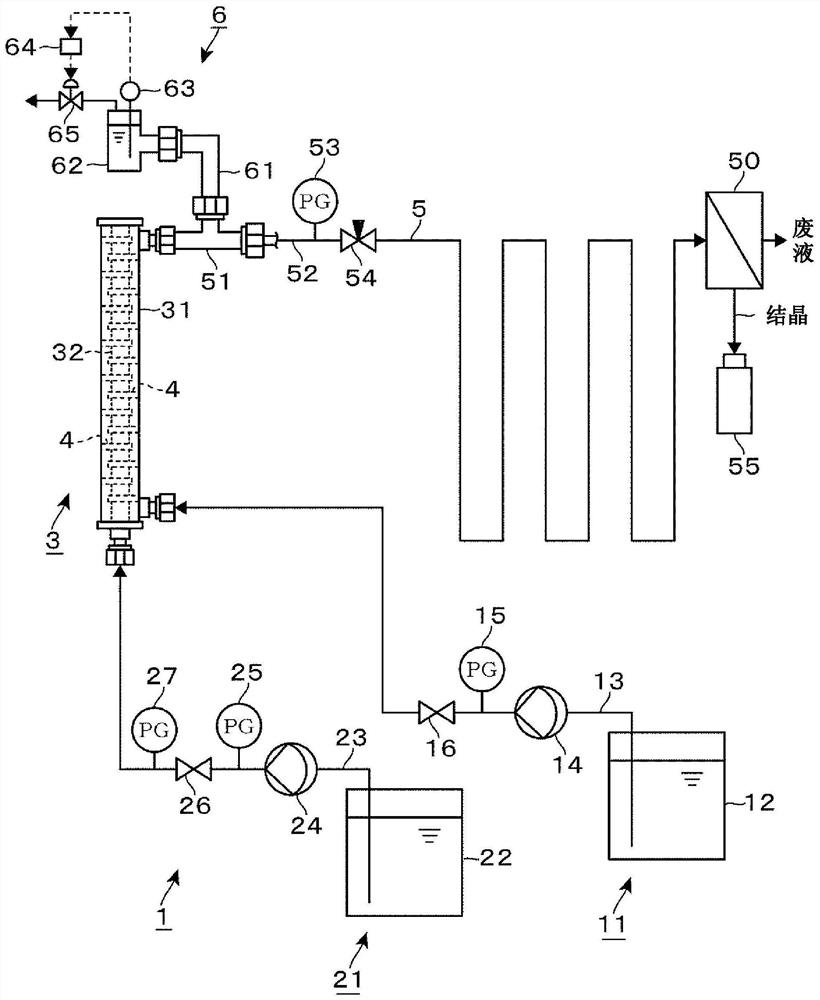

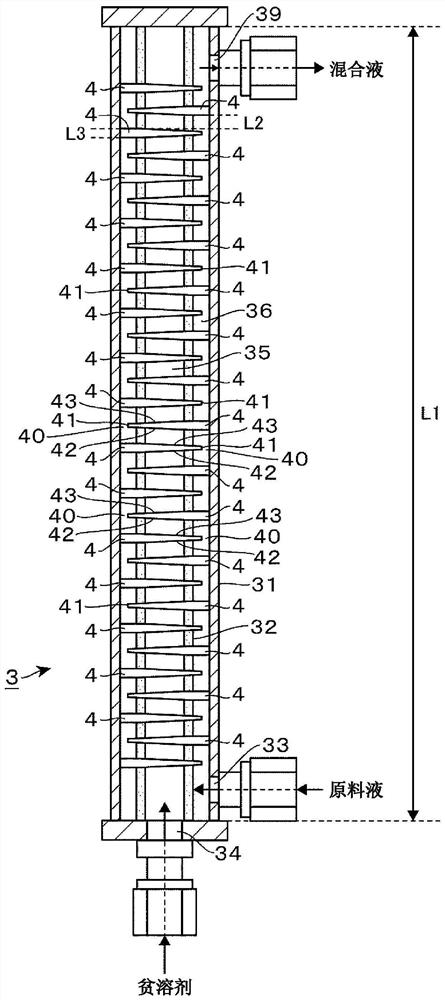

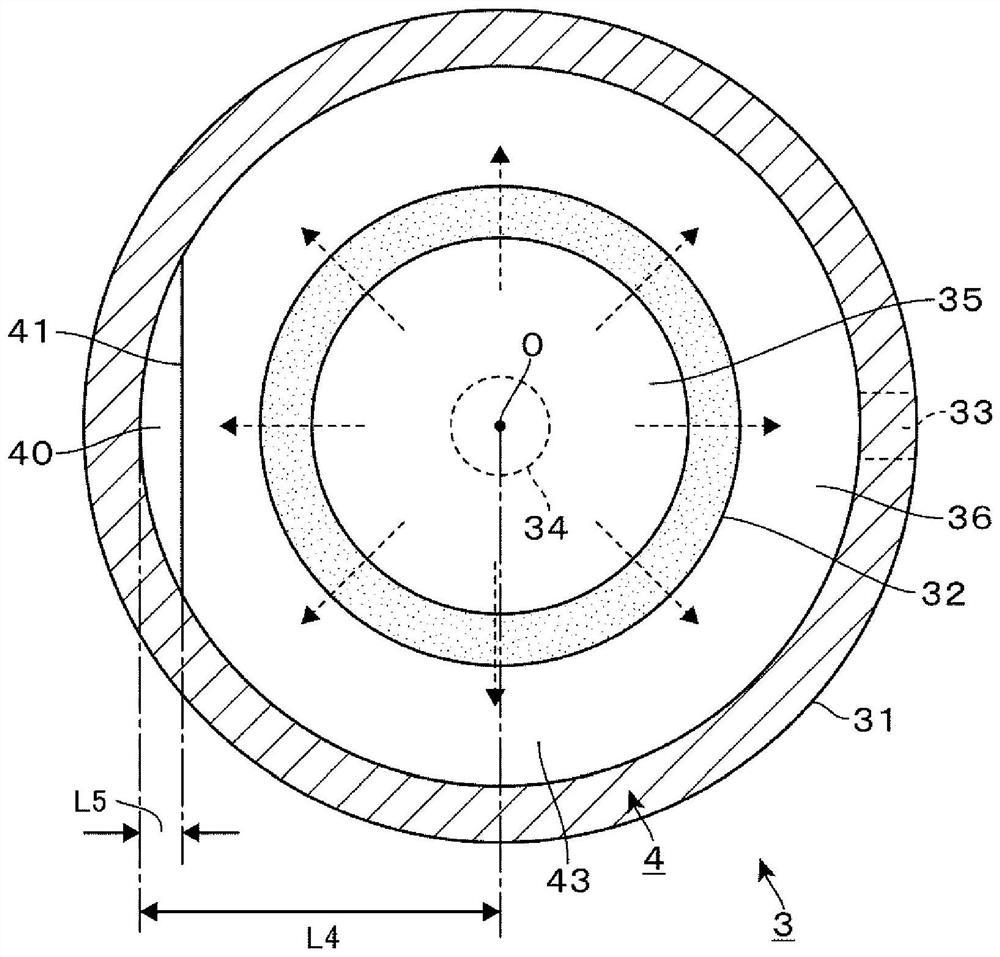

[0036] figure 1 The crystallization apparatus 1 provided with the fluid mixing unit 3 which concerns on 1st Embodiment of this invention is shown, This crystallization apparatus 1 is comprised so that a poor solvent (poor solvent, poor solvent) crystallization may be continuously performed. The crystallization device 1 is equipped with: a raw material liquid supply part 11; a poor solvent supply part 21; a fluid mixing unit 3, which mixes a raw material liquid and a poor solvent to generate a mixed liquid (mixed fluid); an aging tube 5, which makes the crystallization of the target substance Precipitation / growth from the mixed liquid flowing out from the fluid mixing unit 3; solid-liquid separation part 50, which separates the crystals grown in the aging tube 5; exhaust part, which captures and removes the mixed liquid towards the aging tube 5 bubbles. In addition, the crystallization apparatus 1 is configured as a downward flow type device in which the raw material liquid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com