Introducing screw for biogas plants

A technology for conveying screws and screws, which is applied to conveyors, conveyor objects, biochemical equipment and methods, etc., can solve the problems of complex conveying screws, error-prone support and operation, etc., and achieve high-efficiency compaction and reliable conveying. Effective for compaction and reliable conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

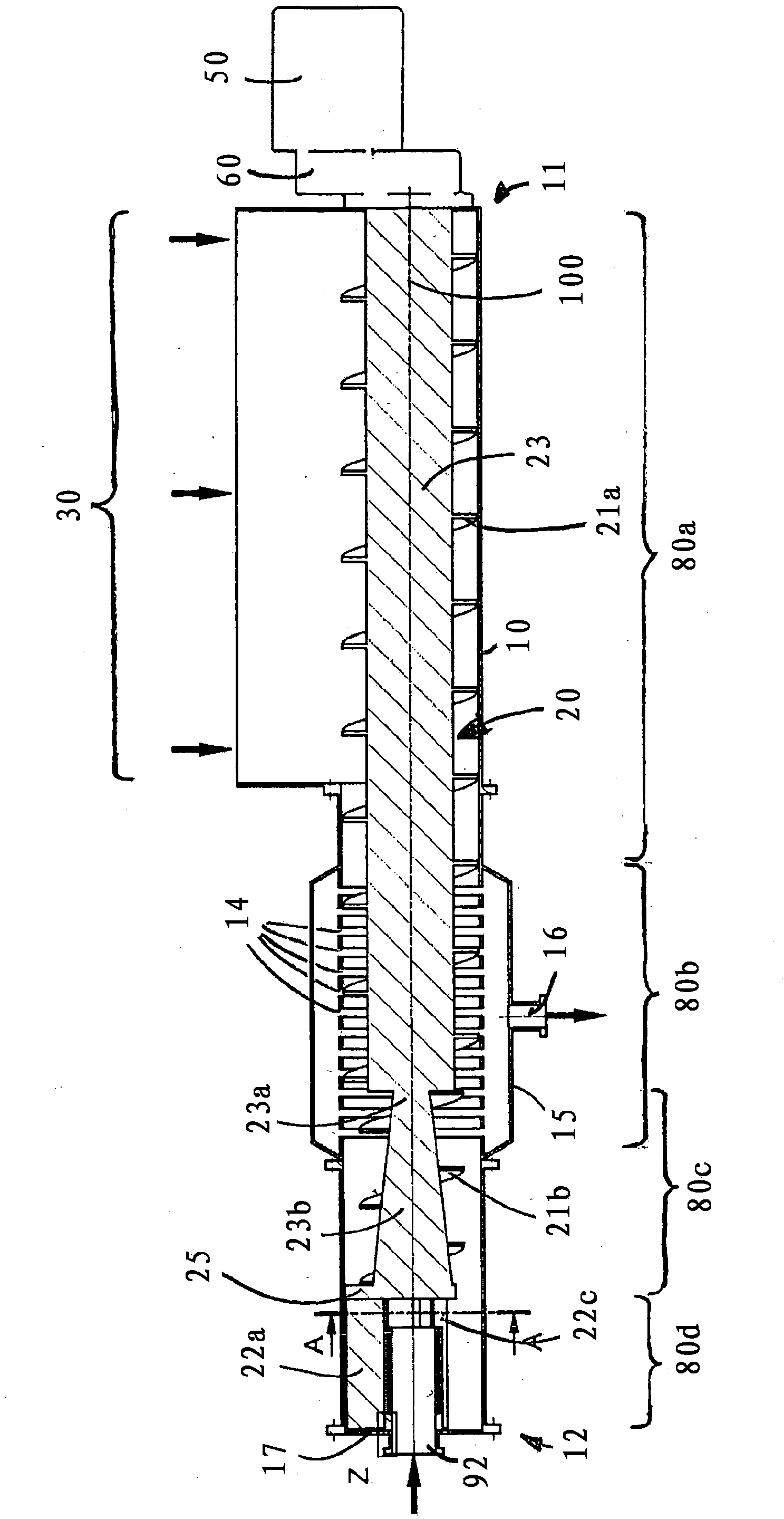

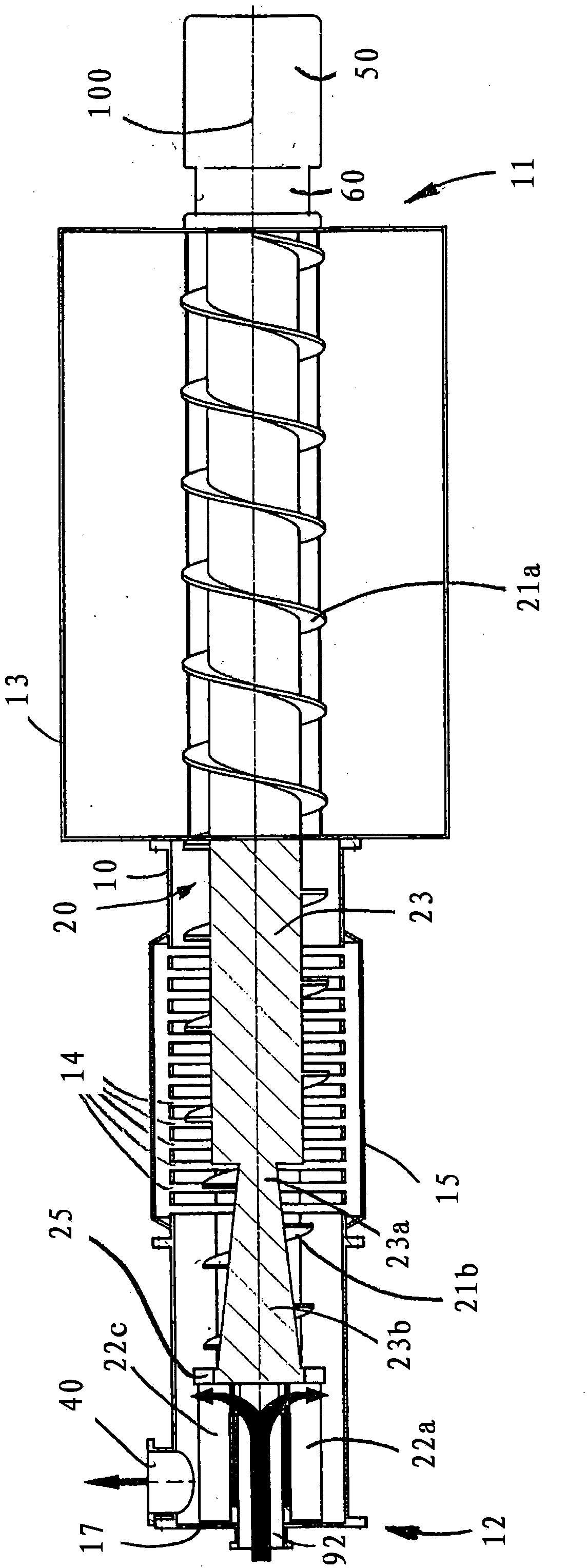

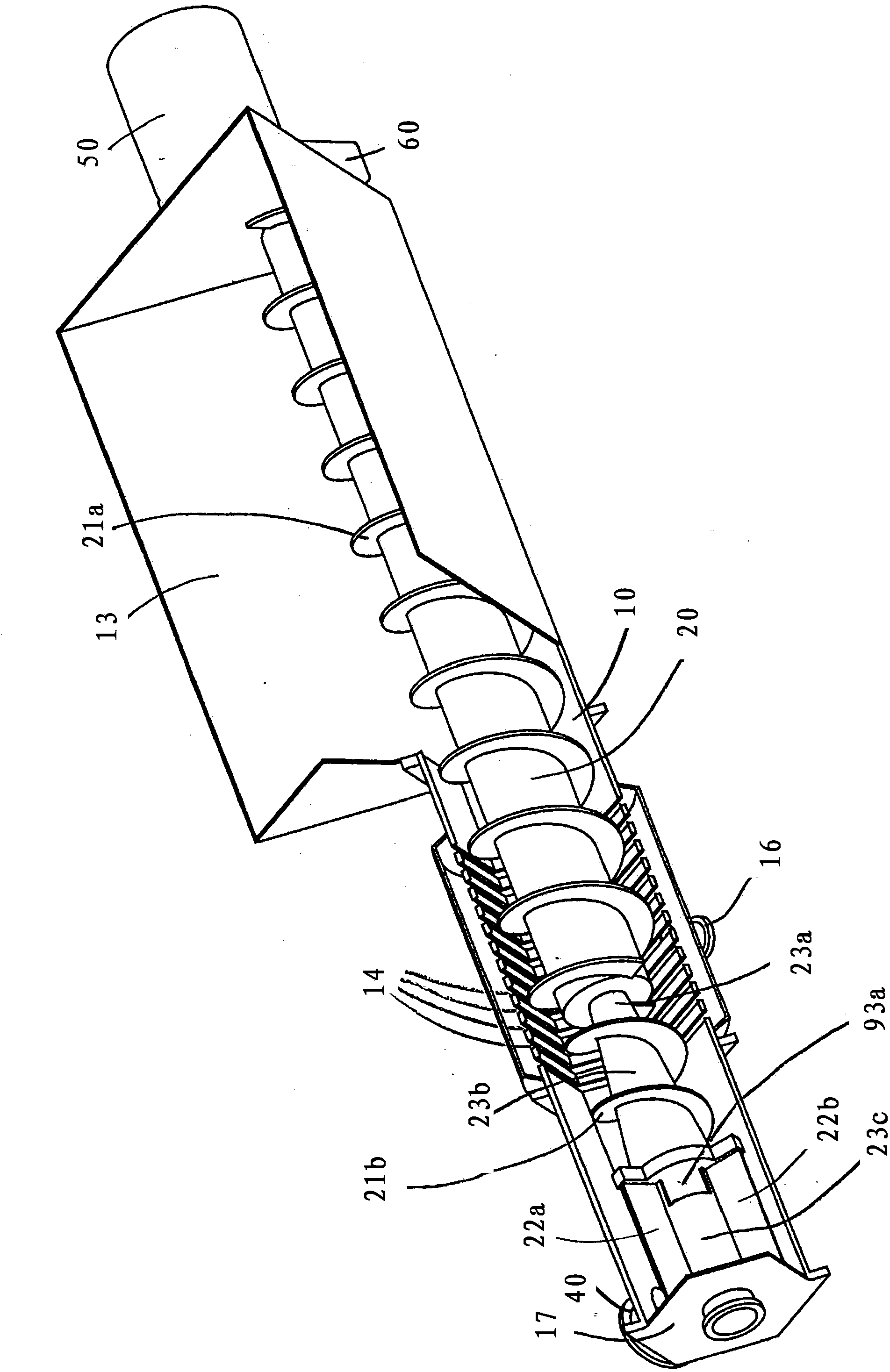

[0039] figure 1 , 2 and 3 show a screw conveyor 1 which basically comprises a screw tube 10 in which a conveyor screw 20 is mounted rotatably about a longitudinal axis 100 . The conveyor screw has a conveyor screw core 23 and screw wings 21a, 21b, 22a-c.

[0040] The inlet 30 extends from the first end 11 of the screw tube 10 over approximately half the total length of the screw tube 10 in the axial direction in the direction of the second end 12 of the screw tube 10 . The inlet 30 is designed as a screw chute 13 and enables the radial introduction of organic solids into the screw tube 10 .

[0041] In the region of the second end 12 there is an outlet 40 configured as a pipe flange, which also extends radially and whose discharge direction is rotated by 90° relative to the longitudinal axis 100 relative to the direction of entry of the organic solids into the inlet 30 .

[0042] At the first end 11 of the screw tube 10 , the electric drive motor 50 is flanged to the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com