Micro LED chip and display panel

A technology of micro-LEDs and chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor display effect of micro-LEDs, and achieve the effect of improving display effect and avoiding optical crosstalk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

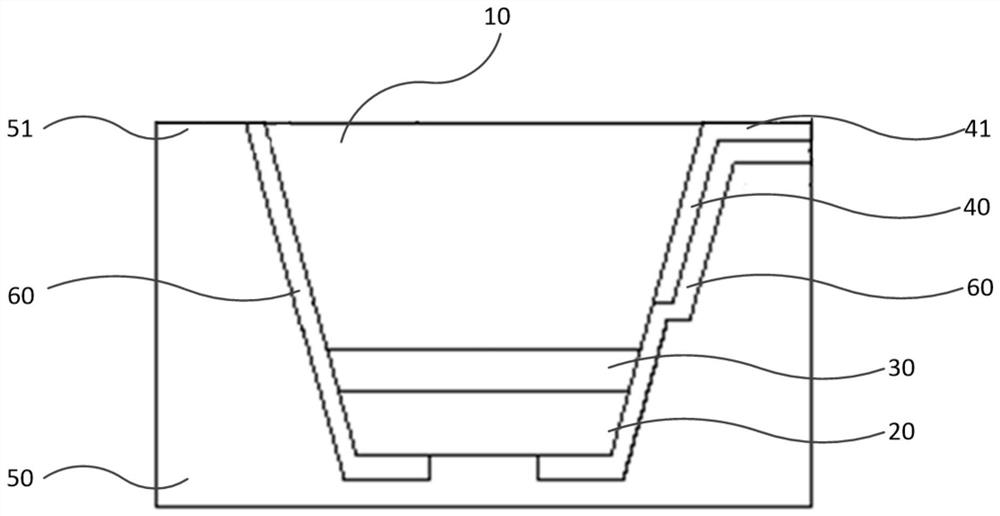

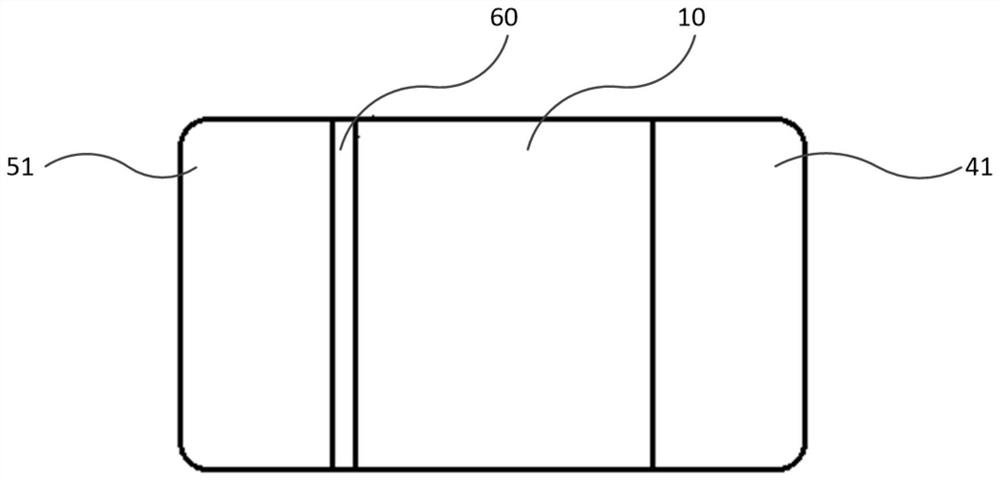

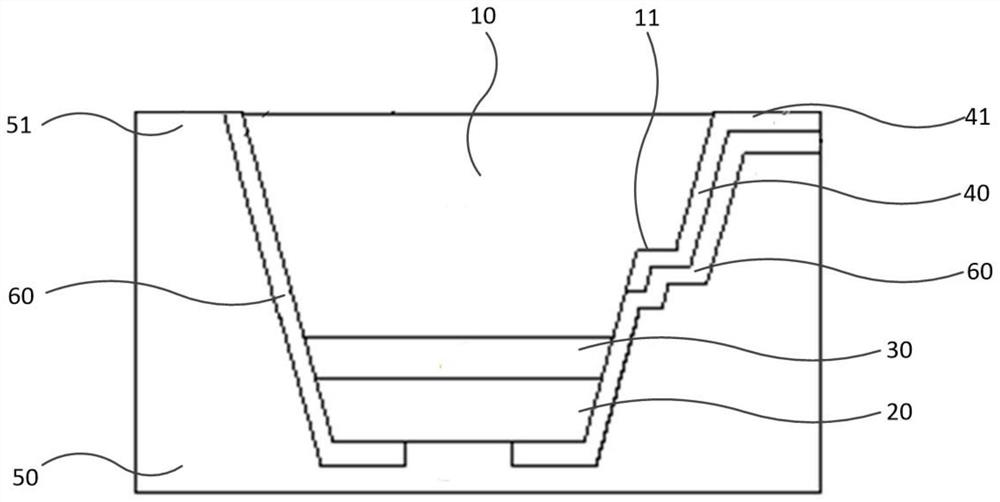

[0042] see Figure 1-Figure 3 , the micro light-emitting diode chip provided by the first embodiment of the present invention includes a first-type semiconductor layer 10, a light-emitting layer 30, a second-type semiconductor layer 20, a first-type electrode layer 40, a second-type electrode layer 50 and an insulating passivation layer 60 , wherein the first type semiconductor layer 10, the light emitting layer 30, and the second type semiconductor layer 20 are stacked in sequence; the first type electrode layer 40 is located on the sidewall of one side of the first type semiconductor layer 10, 10 ohm contact; the insulating passivation layer 60 covers part of the sidewalls of the first type semiconductor layer 10, the sidewalls and bottom surfaces of the first type electrode layer 40, the sidewalls of the light emitting layer 30, the sidewalls of the second type semiconductor layer 20 and Part of the bottom surface; the second type electrode layer 50 covers the insulating pa...

Embodiment 2

[0059] The display panel provided in the second embodiment of the present invention includes the micro-LED chip provided in the above-mentioned embodiment 1, wherein the structure, function and implementation of the micro-LED chip can refer to the specific description in the above-mentioned embodiment, and will not be repeated here.

[0060] The display panel provided in this embodiment can be applied to any display device with a display function including a micro-LED chip, such as a mobile phone, a tablet computer, a smart watch, an e-book, a navigator, a TV, a digital camera, and the like. The display panel provided in this embodiment also has the same advantages as the micro-LED chip provided in the first embodiment, and details are not described herein again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com